Catalog excerpts

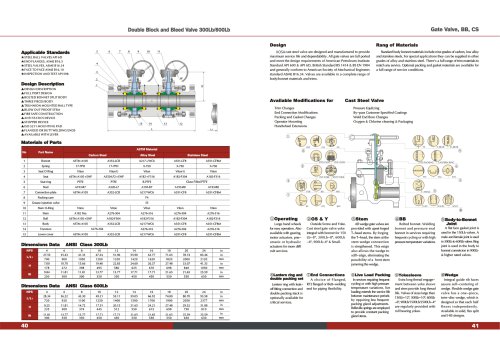

Cast Steel Ball Vavle 2500Lb Ball Vavle, FS, TM (Trunnion Mounted) Cast Steel Ball Vavle 2500Lb Ball Vavle, FS, TM (Trunnion Mounted) Applicable standards: Steel ball valves, API 608/API 6D Steel ball valves, ISO 14313 Fire durable, API 607 Anti static, API 608 Steel valves, ASME B 16.34 Face to face, ASME B 16.10 End flanges, ASME B16.5 Butt welding ends, ASME B16.25 Inspection and test, API 598/API 6D Design description: Full port design BB, Bolted bonnet, split body Three piece body for 12" & above Trunnion mounted ball type Blow-out proof stem Fire durable construction Anti static device Stopper device ISO 5211 Mounting pad Flanged or butt welding ends Available with wg operator Available Modifications for Cast Steel Valve (DOperting Extended lever for easy operation. Also available with gearing, motor actuators, pneumatic or hydraulic actuators for more difficult services. ©End connections A choice of flange, RTJ flanged or butt welding end for piping flexibility. Note: a A 105+ENP optional; 2). Spiral wound construction. Design KOSASteel ball valve are designed and manufactured to provide maximum service life and dependability. All ball valves are full ported and meet the design requirements of American petroleum institute standard API 608 & API 6D, British standard BS 5351 and generally conform to American society of mechanical engineers standard ASME B16.34. Valves are available in a complete range of body/ bonnet materials and trims. Trim changes End connection modifications Packing and gasket changes Operator mounting Flandwheel extensions (©Body & bonnet Split or 3-piece, split body & bonnet for 8" & small. Disassembles easily for repair or replacement of internal components. Rang of Materials Standard body/bonnet materials include nine grades of carbon, low alloy and stainless steels, For special applications they can be supplied in other grades of alloy and stainless steel. There's a full range of trim materials to match any service. Optional packing and gasket materials are available for a full range of service conditions. Pressure equlizing AS or FD Customer specified coatings Weld end bore changes Oxygen & chlorine cleaning & packaging ®AS Anti static. A metallic contact is always granted between ball and stem/body to discharge eventual statics build-op during service. ©Grease-Jet joint Installed in prescriptive part accord with the apply and satisfied with ecumenical situations and realize seal in spot with maintenance easily. ©Packing STD Packing adopt high-performance rubber seal ring, STD Packing and TEFLON use situation for smooth pressure. With spring apply high-pressur-esituation. Graphite packing use situation for high-temperature. ©FD Fire durable. Designed to API 607 or BS 6755 to grant their operation suitability in case of fire. Secondary metal-to-metal seal acts as backup if primary seal is destroyed by fire. Valves ordered for compliance with API 607 will be provided with graphite packing and gaskets. ©DDB Double block & bleed. The body cavity is isolated when the ball is in either fully closed or fully opened position, the medium entrapped in it can easily be bled to avoid over pressure. ©BORE Full bore or reduced bore. Full-bore design provides exceptional flow control. ©GASKET Adopt high-performance rubber seal ring and spiral wound graphite.

Open the catalog to page 1All SuZhou KoSa Environmental Protection CO. catalogs and technical brochures

-

round-ear-loop

5 Pages

-

pp-spunbond-non-woven-fabric

6 Pages

-

one-wire-nose-wire

5 Pages

-

n95-n99-n100-meltblown

5 Pages

-

kf80-kf94-kf99-meltblown

5 Pages

-

full-plastic-nose-wire

6 Pages

-

full-aluminimum-nose-wire

4 Pages

-

flat-ear-loop

6 Pages

-

ffp1-ffp2-ffp3-meltblown

5 Pages

-

es-non-woven-fabric

6 Pages

-

double-wires-nose-wire

5 Pages

-

KOSA INDUSTRIAL VALVES Catalog

51 Pages

-

KOSA FILTRATION Catalog

11 Pages