Catalog excerpts

PRODUCT INTRODUCTION The stepped 3D screen is for large-sized materials. The JONO stepped 3D screen is carried out as a vibrating screen with a circular motion and is driven by a high-performance and equally energy efficient three-phase AC motor. The blind bottom on the infeed side guarantees an efficient utilization of the screening surface, a good material flow, increases the service life of the screening elements and reduces blocking material. The screening elements can be changed easily and quickly and are therefore easy to adjust to the different sized cuttings. ORKING PRINCIPLE The centrifugal force generated by the flywheel vibrator makes screen body to reciprocate forward to form vibration. Under the inertial force, the material is constantly split by the stick. Drop on the screen unit to screen the material out.

Open the catalog to page 1

ECHNICAL DATA Model Machine size Drive unit RPM of main shaft Transmission model Vibration source 30KW 625rpm Pulley drive Flywheel vibrator Input size Screen size Note: The throughput varies with the size of the screen. FEATURES The vibrator is modular in design and can be adjusted by increasing or decreasing the weight. The structure design is reasonable, and the screen body and the screen mesh have good vibration resistance. The structure can be effectively isolated by the two-layer vibration-damping structure design.

Open the catalog to page 2All Suzhou JONO Environmental Technology Co. catalogs and technical brochures

-

LHASA-JONO ENVIRO

4 Pages

-

Pulping Machine - Jono

2 Pages

-

Baler - Jono

2 Pages

-

Rotary Belt Conveyor - Jono

2 Pages

-

Bag Opener/Crusher -Jono

2 Pages

-

Leo Primary Shredder - Jono

2 Pages

-

Draco Bag Opener - Jono

2 Pages

-

Rotary Air Separator - Jono

2 Pages

-

Mobile Trommel Screen - Jono

2 Pages

-

Trommel Screen - Jono

2 Pages

-

Vibrating Screen - Jono

2 Pages

-

Star Screen - Jono

2 Pages

-

Flip-flow Screen - Jono

2 Pages

-

Ballistic Screen - Jono

2 Pages

-

Disc Screen - Jono

2 Pages

-

AI Sorter-Jono

2 Pages

-

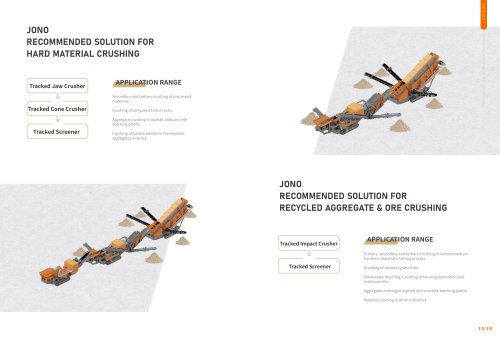

JONO

17 Pages