Catalog excerpts

PRODUCT INTRODUCTION FLIP FLOW SCREEN The Flip-Flow action stretches and slackens the screen mats very quickly. This action prevents build-up of fines material in corners or pegging in the screen mat apertures. The JONO Flip-Flow can screen to very small particle sizes because of this unique action. It is used in dry screening construction waste, crushed stone, sand, compost, wood chips, recycled glass and carpet fibres, slag and recycled electronic parts to name only a few applications. ORKING PRINCIPLE The centrifugal force generated by the flywheel vibrator makes screen body to reciprocate forward to form vibration. The flexible screen plate is repeatedly relaxed and tensioned under the action of inertial force. Thereby the small-sized material can be well screened out.

Open the catalog to page 1

ECHNICAL DATA Model Machine size Drive unit RPM of main shaft Transmission model Vibration source 15KW 750rpm Pulley drive Flywheel vibrator Input size Screen size Throughput capacity Note: The throughput varies with the size of the screen. FEATURES The vibrator is modular in design and can be adjusted by increasing or decreasing the weight. Longer service life due to the Germany-imported flexible screen unit. The structure design is reasonable, and the screen body has good vibration resistance. Screen replacement is convenient.

Open the catalog to page 2All Suzhou JONO Environmental Technology Co. catalogs and technical brochures

-

LHASA-JONO ENVIRO

4 Pages

-

Pulping Machine - Jono

2 Pages

-

Baler - Jono

2 Pages

-

Rotary Belt Conveyor - Jono

2 Pages

-

Bag Opener/Crusher -Jono

2 Pages

-

Leo Primary Shredder - Jono

2 Pages

-

Draco Bag Opener - Jono

2 Pages

-

Rotary Air Separator - Jono

2 Pages

-

Mobile Trommel Screen - Jono

2 Pages

-

Trommel Screen - Jono

2 Pages

-

Vibrating Screen - Jono

2 Pages

-

Stepped 3D Screen - Jono

2 Pages

-

Star Screen - Jono

2 Pages

-

Ballistic Screen - Jono

2 Pages

-

Disc Screen - Jono

2 Pages

-

AI Sorter-Jono

2 Pages

-

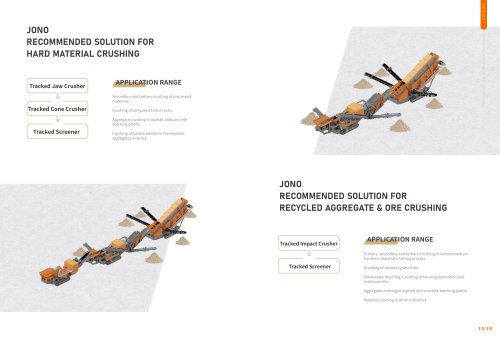

JONO

17 Pages