Website:

Sutton Tools

Website:

Sutton Tools

Catalog excerpts

Vacuum Heat Treatment The best in vacuum heat treatment STC offers premium quality vacuum heat treatment using the latest technology from Abar Ipsen. Our 1 2 bar TurboTreater® furnace, with convection heating, has enabled STC to gain Ford (FMC) provisional supplier status, recognising STC as a heat treatment supplier for high pressure die casting applications. The patented nozzle design, cylindrical hot zone and sophisticated computer control gives the TurboTreater® a competitive edge in quenching large workpieces, up to 1 tonne, reliably and repeatedly. Our 6 bar Turbo-Vac furnace features...

Open the catalog to page 2

Plasma Nitriding_ Surface Technology Coatings introduced Australia's first commercial plasma nitriding facility in 2002. The revolutionary NitroPlas system generates a plasma on a large cage surrounding the entire workload in a vacuum furnace. The workload is uniformly and efficiently heated by the cage. Problems associated with conventional plasma nitriding, where the plasma is generated on the parts, such as over heating by the hollow cathode effect and damage caused by arcing are thus greatly reduced. The NitroPlas white layer is hard and tough reducing the need for post-treatment...

Open the catalog to page 3

PVD Hard Thin Film Coatings Surface Technology Coatings is Australia's only company providing a combined coating, nitriding and heat treatment service to industry with ultra-hard thin film coatings based on physical vapour deposition (PVD) technology. Using world-leading technology coatings are available to solve a wide range of problems relating to friction and wear, thereby improving tool performance and increasing tool life. Tools or components to be coated are first inspected to insure suitability for coating, and then cleaned using an automatic multi-step process to ensure that they...

Open the catalog to page 4

Materials that can be coated include carbides, high speed steels, hot work tool steels, certain copper alloys, stainless steels and nitridable alloy steels. Cold work tool steels can be coated if they are tempered at least three times at the maximum secondary hardening temperature. In general all materials that can withstand a coating temperature of 500°C, without softening or distortion, can be successfully PVD coated. Certain coatings are applied at 600°C and these are in general only suitable for carbide substrates. Brazed parts can also be coated if the brazing material is temperature...

Open the catalog to page 5

Tool surfaces that can be coated after specialised cleaning • Milled or Machined Surfaces High temperature brazing • Black or steam oxide surfaces • Nitrided surfaces • Polished or lapped surfaces • Glass beaded surfaces These surfaces can be successfully coated. However due to varying surface conditions, testing may be required to achieve the best coating adhesion. Other surfaces requiring special treatment before coating Rusted surfaces • Tools with paint or wax markings • Tools with layout die or protective plastic coatings • Chrome plated surfaces • Nickel plated surfaces • Used dies or...

Open the catalog to page 6All Sutton Tools catalogs and technical brochures

-

Ox

2 Pages

-

CrN

2 Pages

-

TiN

2 Pages

-

TiCN

2 Pages

-

TiAlN

2 Pages

-

Aldura

2 Pages

-

Alcrona

2 Pages

-

DH Series Drills

12 Pages

-

Fasteners Black Book

1 Pages

-

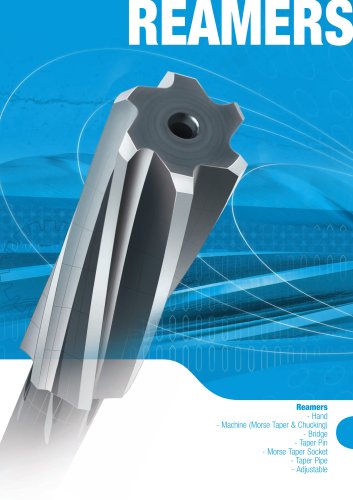

Euro Catalogue: Reamers

14 Pages

-

Euro Catalogue: Endmills

42 Pages

-

Euro Catalogue: Carbide Endmills

22 Pages

-

Euro Catalogue: Taps ISO

40 Pages

-

Euro Catalogue: Taps DIN

142 Pages

-

Euro Catalogue: Countersinks

8 Pages

-

Euro Catalogue: Drills HSS

88 Pages

-

Euro Catalogue: Drills Carbide

18 Pages

-

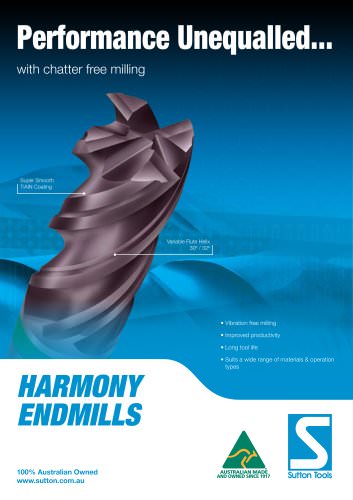

Sutton Tools Harmony Endmill

4 Pages

-

Sutton Tools STF Endmill

2 Pages

-

Sutton Tools VH / XH Taps

2 Pages

-

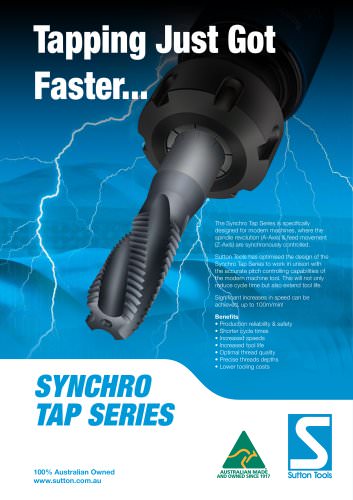

Sutton Tools Synchro Tap Series

12 Pages

-

Sutton Tools R40 Uni Drill

6 Pages

-

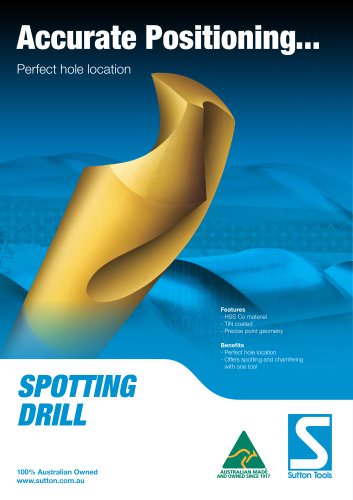

Sutton Tools Spotting Drill

2 Pages

-

Sutton Tools DXS / DXJ Drill

6 Pages

-

Engineers Black Book

1 Pages

-

Sutton Tools Carbide Burs

4 Pages