Website:

Sunfab Hydraulics

Website:

Sunfab Hydraulics

Catalog excerpts

Sunfab’s SCM 025-108 M2 is a range of robust axial piston motors with cartridge flange especially suitable for winch-, slewing-, wheel- and track drives. Other advantages: SCM 025-108 M2 is of the bent-axis type with spherical pistons. The design results in a compact motor with few moving parts, high starting torque and high reliability. The SCM 025-108 M2 covers the entire displacement range 25108 cmᶟ ⁄rev. at a maximum pressure of 400 bar. • Smooth operation over the entire speed range • High maximum speed • High efficiency • Suitable for applications with high angular accelerations due to its high rotary stiffness It´s well dimensioned, double tapered roller bearings permit high shaft loads and lead to excellent speed characteristics. It´s high level of reliability is based on the choice of materials, hardening methods, surface structures and the quality assured manufacturing process. Motor SCM 025-108 M2 Displacement Working pressure max intermittent max continuous Revolutions max intermittent max continuous min continuous Power max intermittent max continuous Starting torque theoretical value Moment of inertia (x 10-3) Weight Data concerning RPM are based on maximum premitted peripheral velocity of the tapered roller bearing. Max intermittent power data may vary dependent on application. For further information please contact Sunfab. Continuous power data are based on maximum output power without external cooling of the motor housing. Intermittent duty is defined as follows: max 6 seconds per minute, e g peak RPM when unloading or accelerating. GB - Printed: 04/02/2014 06:00:35 - Page 1/8 Sunfab Hydraulics AB, Box 1094, SE-824 12 Hudiksvall, Sweden. Tel: +46 650-367 00, Fax: +46 650-367 27, E-mail: sunfab@sunfab.se Web: www.sunfab.com

Open the catalog to page 1

VERSIONS, MAIN DATA Example SC Sunfab Compact, bent-axis design 90° Mount flange vertical * 90° Mount flange horizontal * Nitrile High pressure, nitrile Viton External drainage X = Standard, preferred (X) = Available, option O = Available on request, contact Sunfab GB - Printed: 04/02/2014 06:00:35 - Page 2/8 Sunfab Hydraulics AB, Box 1094, SE-824 12 Hudiksvall, Sweden. Tel: +46 650-367 00, Fax: +46 650-367 27, E-mail: sunfab@sunfab.se Web: www.sunfab.com

Open the catalog to page 2

GB - Printed: 04/02/2014 06:00:35 - Page 3/8 Sunfab Hydraulics AB, Box 1094, SE-824 12 Hudiksvall, Sweden. Tel: +46 650-367 00, Fax: +46 650-367 27, E-mail: sunfab@sunfab.se Web: www.sunfab.com

Open the catalog to page 3

GB - Printed: 04/02/2014 06:00:35 - Page 4/8 Sunfab Hydraulics AB, Box 1094, SE-824 12 Hudiksvall, Sweden. Tel: +46 650-367 00, Fax: +46 650-367 27, E-mail: sunfab@sunfab.se Web: www.sunfab.com

Open the catalog to page 4

The drainage oil should have a maximum temperature of 75 °C with a Nitrile shaft seal and 90 °C with a Viton shaft seal. These temperatures must not be exceeded. The housing pressure must be equal to or greater than the external pressure on the shaft seal. Factors affecting the choice of shaft seal include the hydraulic motor housing pressure and the drainage oil temperature. Shaft loads The life of the motor is highly dependent on the bearing life. The bearings are affected by operating conditions such as speed, pressure, oil viscosity and filtration. External load on the shaft, as well as...

Open the catalog to page 5

Excessive system temperature reduces the life of the shaft seal and can lower the oil viscosity below the recommended level. A system temperature of 60 °C and a drain flow temperature of 90 °C must not be exceeded. Counter pressure valve Cooling/flushing of the motor housing can be needed to keep the drain flow temperature at an acceptable level. Suggested flow: Flushing l/min 2-8 4-10 6-12 Counter pressure valve Flushing valve Housing flushing can be built up with the help of a flushing valve or taken directly from the return line. When the return pressure is too low this is compensated...

Open the catalog to page 6

Hydraulic fluids Recommended oil velocity in pressure line max. 7 m/sec High performance oils meeting ISO specifications – such as HM, DIN 51524-2 HLP, or better – must be used. A min. viscosity of 10 cSt is required to keep the lubrication at a safe level. Cleanliness according to ISO norm 4406, code 16/13. Additional technical data Noise levels and bearing life calculations available on request. Please contact Sunfab! Useful formulaes Required flow rate Q = D = displacement, cm3⁄revolution n = speed, revolution⁄min P = power, kW Q = flow rate, litres⁄min ηv = volumetric efficiency ηhm =...

Open the catalog to page 7

WARNING When the motor is in use: 1. Do not touch the pressure pipe 2. Beware of rotating parts 3. The motor and pipes can reach high temperatures Sunfab reserves the right to make changes in design and dimensions without notice. Printing and typesetting errors reserved. GB - Printed: 04/02/2014 06:00:35 - Page 8/8 Sunfab Hydraulics AB, Box 1094, SE-824 12 Hudiksvall, Sweden. Tel: +46 650-367 00, Fax: +46 650-367 27, E-mail: sunfab@sunfab.se Web: www.sunfab.com

Open the catalog to page 8All Sunfab Hydraulics catalogs and technical brochures

-

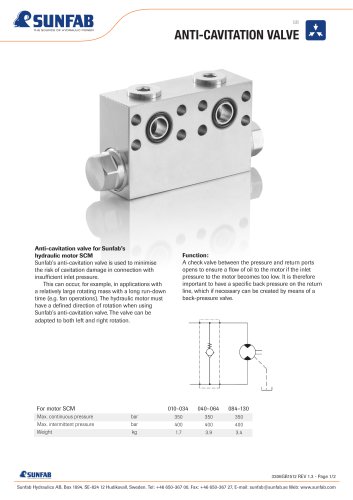

ANTI-CAVITATION VALVE

2 Pages

-

ANTI-CAVITATION VALVE

2 Pages

-

Flushing Valve

2 Pages

-

Speed Sensor

4 Pages

-

DIODE GATE

2 Pages

-

INJECTOR

2 Pages

-

SAM 010-130 DIN

7 Pages

-

SVH 130

20 Pages

-

SCM 012-130 DIN

7 Pages

-

SCM 010-130 SAE

12 Pages

-

SCM 010-130 ISO

12 Pages

-

SAP 084, 108 DIN Optimised

4 Pages

-

SAPT 090, 130 DIN

4 Pages

-

SAP 012-108 DIN

4 Pages

-

SCPD 76/76 DIN

4 Pages

-

SLPD 40/20-64/32 SAE

4 Pages

-

SLPD 20/20-64/32 DIN SAVTEC

5 Pages

-

SLPD 20/20-64/32 DIN

4 Pages

-

SCPD 56/26 DIN By-Pass

4 Pages

-

SCPD 56/26 DIN

4 Pages

-

SCM 012-130 SAE

12 Pages

-

SCPT 090, 130 DIN

4 Pages

-

SCP 012-130 ISO

7 Pages

-

SCP 084, 108 DIN Optimised

4 Pages

-

SAP 040-064 DIN

4 Pages

-

SCP 012-108 DIN

4 Pages

-

Product Catalogue

25 Pages

-

Accessories Catalog

28 Pages

-

axial piston hydraulic motor SAE

11 Pages

-

Anti-Cavitation Valve

2 Pages

-

Splitter gearbox SZ 121

2 Pages

-

SVH 062, 092, 112

16 Pages

-

SC 5012-5108 SAE

2 Pages

-

SC 012-108 DIN

2 Pages

-

suction oil filter

2 Pages

-

hydraulic relief valve

2 Pages

-

oil tank

2 Pages

-

power take-off for engine

2 Pages

-

dual shaft gearbox

2 Pages

-

variable flow hydraulic pump

16 Pages

-

hydraulic truck pump

2 Pages

-

SCM 047-090 M2

6 Pages

Archived catalogs

-

axial piston hydraulic motor

10 Pages