Catalog excerpts

Copyright Sumitomo (SHI) Cyclo Drive Germany GmbH 2018. All rights reserved. Reproduction in part or whole is not permitted without our prior approval. Whilst every care has been taken in preparation of this catalogue, no liability can be accepted for any errors or omissions. Modifications reserved. Copyright Sumitomo (SHI) Cyclo Drive Germany GmbH 2018. Alle Rechte vorbehalten. Nachdruck, auch auszugsweise, nur mit unserer Genehmigung gestattet. Die Angaben in diesem Katalog wurden mit größter Sorgfalt auf ihre Richtigkeit überprüft. Trotzdem kann für eventuell fehlerhafte oder...

Open the catalog to page 2

Product description The SERVO P ecision Gears Series are compact speed reducers with low backlash, made in aluminium and ideal for all low weight applications. The SERVO 100 is custom made for Motion Precision Control, the SERVO 6000 range is recommended for Medium Positioning Control. Features & Benefits • Low backlash • High shock load capacity • High efficiency • Compact size • Low noise • Long lifetime • Maintenance free • Unlimited mounting flexibility • Cost effective Application Low Backlash Series for Positioning Control • Conveyors (tact feed, sorter, palletizer) • Materials...

Open the catalog to page 3

AVAILABLE REDUCTION RATIOS ...13

Open the catalog to page 4

The Cyclo Principle There are essentially four major components in the Cyclo gearbox: 1. High speed shaft with eccentric bearing 3. Ring gear housing with pins and rollers 4. Slow speed shaft or flange with pins and rollers Das Cyclo Prinzip Das CYCLO-Getriebe setzt sich aus 4 Hauptbestandteilen zusammen: 3. Bolzenring mit den Bolzen und Rollen 4. Abtriebswelle mit Bolzen und Rollen Pins & Rollers Cycloidal Disc /Kurvenscheibe Bearing / Walzkorper Cycloidal Disc tollers/Aussenrollen Eccentric/Exzenter High Speed Shaft High Speed Shaft High Speed Shaft Slow Speed Shaft Slow Speed Shaft...

Open the catalog to page 5

SERVO Selection 1. Determine the working cycle of the application 1. Arbeitszyklus der Anwendung festlegen = load duty cycle [%] = axial load on output shaft [N] = allowable axial load on output shaft [N] = equivalent radial load on output shaft [N] = allowable radial load on output shaft[N] = mean input speed during acceleration [min-1] = mean input speed during braking [min-1] = mean input speed during cycle [min-1] =mean input speed limited by ED [min-1] = max. allowable input speed of gear size [min-1] = input speed with uniform movement [min-1] = acceleration torque [Nm] =allowable...

Open the catalog to page 7

SERVO Selection 2. Flow chart for selection Calculation of mean input speed mittlere Antriebsdrehzahl berechnen Calculation of equivalent torque Vergleichsdrehmoment berechnen Calculation of load duty cycle Einschaltdauer berechnen Temporary selection of a gear size: select the smallest gear size [Tab. 19-22] that accomplishes the following requirement: T 2V < T 2N Vorläufige Auswahl einer Getriebegröße: Auszuwählen ist die kleinste Größe [[Tab. 19-22], die folgende Anforderung erfüllt: T 2V < T 2N Choose bigger gear size höhere Getriebegröße wählen

Open the catalog to page 8

Features & Benefits Eigenschaften & Vorteile The SERVO 6000 series have the following features and benefits simular to the standard CYCLO DRIVE 6000 series one. High shock load capacity Compact size High efficiency Low noise Maintenance free Long life Unlimited mounting flexibility. Die Serie SERVO 6000 bietet wie die Serien CYCLO DRIVE 6000 folgende Eigenschaften und Vorteile: Hohe Überlastkapazität Kompakte Bauweise Hoher Wirkungsgrad Niedriger Geräuschpegel Wartungsfreiheit Lange Lebensdauer Flexibilität im Anbau In addition the backlash has been reduced. Due to the special tooth profile...

Open the catalog to page 11

CYCLO DRIVE Input elements Antriebselement (Tab. 28) Shaft position Wellenlage Grease lubrication for life Lebensdauerfettschmierung Mounting Bauform Reduction ratio Übersetzung Input X = Motor adaptor - = free shaft Antriebsseite X = Motoradapter - = freie Welle LB = Low Backlash = Standard Backlash LB = reduziertes Verdrehspiel = Standard Verdrehspiel S = Special design S = Sonderausführung Shaft specification G = Metric shaft, tolerance k6 acc. to DIN Y = Inch shaft = Metric passing h6 E = European shaft Wellenausführungen G = metrische Welle, Toleranz k6 nach DIN Y = Inch Welle =...

Open the catalog to page 13

Available Reduction Ratios Frame size Baugröße Reduction ratio Übersetzung Backlash Verdrehspiel (The guaranteed maximum backlash is < 6 arcmin, except ratio 6, where the max. backlash is < 12 arcmin) (Das garantierte max. Verdrehspiel ist < 6 arcmin, außer bei Übersetzung 6, wo es bei < 12 arcmin liegt) Max.allow. input speed max. zul Antriebsdrehzahl 4000 r/min (10 min cyclo, 50% ED) 4000 U/min (10 min zyklus, 50% ED) Standard Ratio / Vorzugsübersetzungen On Request / auf Nachfrage Note: 1. Output torque rating shows mechanical rating of CYCLO DRIVE. The acceleration and deceleration peak...

Open the catalog to page 14

Sumitomo DriveTechnologies Sectional drawing

Open the catalog to page 16

Single reduction speed reducers i = 6 to 87 Einstufige Getriebe i = 6 bis 87 Max. input speed is 4000 min-1 at 50% ED. Die max. Antriebsdrehzahl ist 4000 min-1 bei 50% ED. n1R = Input speed with uniform movement [min-1] i = Reduction ratio P1 = Allowable input power [kW] T2n = Allowable output torque [Nm] T2A = Max. acceleration or n1R = Antriebsdrehzahl des gleichformigen Laufs [min-1] i = Ubersetzung n2 = Abtriebsdrehzahl [min-1] T2n = zulassiges Abtriebsdrehmoment [Nm] T2A = max. Beschleunigungs- und Bremsdrehmoment [Nm]

Open the catalog to page 17

Single reduction speed reducers i = 6 to 87 Einstufige Getriebe i = 6 bis 87 Max. input speed is 4000 min-1 at 50% ED. Die max. Antriebsdrehzahl ist 4000 min-1 bei 50% ED. n1R = Input speed with uniform movement [min-1] n1R P1 = Allowable input power [kW] P1 T2n = Allowable output torque [Nm] T2n = Antriebsdrehzahl des gleichformigen Laufs [min-1] = Ubersetzung = Abtriebsdrehzahl [min-1] = zulassige Antriebsleistung [kW] = zulassiges Abtriebsdrehmoment [Nm] = max. Beschleunigungs- und Bremsdrehmoment [Nm]

Open the catalog to page 18All SUMITOMO (SHI) Cyclo Drive Germany GmbH catalogs and technical brochures

-

Paramax 9000 series

281 Pages

-

Helical Shaft Mount (HSM)

58 Pages

-

Bevel Buddybox 4

60 Pages

-

Motion Control DrivesE CYCLO

28 Pages

-

BEVEL BUDDYBOX 4

248 Pages

-

Cyclo® BBB5

270 Pages

-

Fine Cyclo®

123 Pages

-

PARAMAX ® 9000 Series

281 Pages

-

Fine Cyclo UA Brochure

2 Pages

-

Fine Cyclo Flyer

2 Pages

-

Precision Drives Product Catalog

20 Pages

-

Fine Cyclo F4CF – UA 25

2 Pages

-

Fine Cyclo F4CFS–UA 115

4 Pages

-

Fine Cyclo F4C–C 25

4 Pages

-

Paramax 9000

352 Pages

-

Neo Hyponic

120 Pages

-

Servo 100

58 Pages

-

Servo 6000 series

6 Pages

-

Cyclo® Drive 6000

139 Pages

-

Paramax® 9000

352 Pages

-

HSM series

58 Pages

-

Astero series

186 Pages

-

IB Series catalogues

94 Pages

-

Servo Planetary Gears EPG

6 Pages

-

Servo-Planetary Gears

4 Pages

-

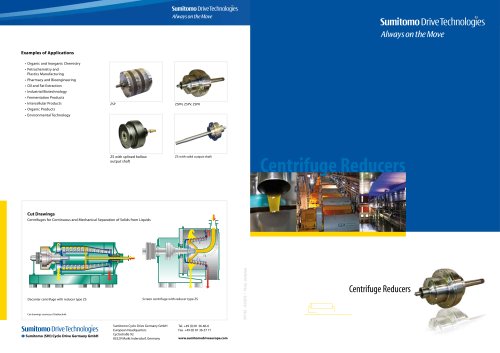

Centrifuge reducers

2 Pages

-

Fine Cyclo®

114 Pages

Archived catalogs

-

Product overview

16 Pages