Catalog excerpts

Fine Cyclo Zero Backlash Speed Reducers Spielfreie Getriebe Catalogue 999016/EN/DE - 08/2010

Open the catalog to page 1

3 Sumitomo's Fine Cyclo Precision Gears for Robotics, Machine Tool Industry and Automation are torsionally stiff, compact and cost effective. Zero backlash speed reduction assemblies for all applications which demand the highest precision and stiffnes. Features & Benefits FA-Series for point to point applications Cyclo system incorporating three discs and a single eccentric. Available in four mounting versions. FT-Series for smooth traverse applications. Cyclo system incorporating two discs and a single eccentric For the highest transmission accuracy with minimum speed ripple and minimum...

Open the catalog to page 4

FINE CYCLO 4 The rotation of the cycloid discs is transmitted to the slow speed shaft via the pins and rollers projecting through holes in the cycloid discs. The pins of the slow speed shaft and sometimes the pins of the ring gear, too are equipped with rollers so that the torque transmitting parts of the CYCLO gearbox roll smoothly. Die reduzierte Drehbewegung der Kurvenscheiben wird über Bolzen, die in die Bohrungen der Kurvenscheiben eingreifen, auf die Abtriebswelle übertragen. Auf die Bolzen der Abtriebswelle und manchmal auch auf die Bolzen des Bolzenrings sind Rollen aufgesteckt, so...

Open the catalog to page 5

5 i = n1 = -z n2 i = n1 = z + 1 n3 i = n2 = z + 1 n3 z i = n2 = - 1 n1 z i = n3 = 1 n1 z + 1 i = n3 = z n2 z + 1 n n3 2 Input: Input shaft (n1) Output: Output shaft (n2) Fixed: Ring gear housing (n3) Input: Input shaft (n1) Output: Ring gear housing (n3) Fixed: Output shaft (n2) Input: Output shaft (n2) Output: Ring gear housing (n3) Fixed: Input shaft (n1) Input: Output shaft (n2) Output: Input shaft (n1) Fixed: Ring gear housing (n3) Input: Ring gear housing (n3) Output: Input shaft (n1) Fixed: Output shaft (n2) Input: Ring gear housing (n3) Output: Output shaft (n2) Fixed: Input shaft...

Open the catalog to page 6

6 Fine Cyclo - FA Tab.1 149 349 668 1390 2570 3900 FCA 15 G A 25 G A 35 G A 45 G A 65 G A 75 G Rated output torque [Nm] at n1m = 1500 min -1 / Nennabtriebsdrehmoment [Nm] bei n1m = 1500 min -1 n1m = mean input speed / mittlere Antriebsdrehzahl Single reduction ratios / Einstufige Übersetzungen Version FC-A Standard Reduction Assembly without bearing support for output flange .. 6 mounting sizes .. single reduction ratios 29, 59, 89, 119, 179 .. reduction kit for integrated design .. compact assembly by utilising customers bearing support .. rated output torque up to 5.140 Nm .. acceleration...

Open the catalog to page 7

7 Fine Cyclo - FA FA Version F1C-A with output flange and single crossed roller bearing .. 6 mounting sizes .. single reduction ratios 29, 59, 89, 119, 179 .. bearing supported output flange .. rated torque up to 5,140 Nm .. acceleration torque up to 7,610 Nm .. allowable peak torque for emergency stop up to 24,000 Nm .. input speeds up to 6,150 rpm .. Lost Motion achievable down to 1 arcmin .. motor connection via intermediate flange .. optional connection to keyless motor shaft using clamp ring Version F1C-A Flanschversion mit abtriebsseitiger Kreuzrollenlagerung .. 6 Baugrößen .....

Open the catalog to page 8

8 Fine Cyclo - FA Version F2C-A Speed Reducer with output flange and integrated taper roller bearings .. 4 mounting sizes .. single reduction ratios 29, 59, 89, 119, 179 .. smaller overall dimensions than F1C-A .. taper roller bearings with high moment ratings .. rated output torque up to 1,830 Nm .. acceleration torque up to 2,910 Nm .. allowable peak torque for emergency stop up to 7,210 Nm .. input speeds up to 6,150 rpm .. Lost Motion achievable down to 1 arcmin .. motor connection via intermediate flange .. optional connection to keyless motor shaft using clamp ring .. optional...

Open the catalog to page 9

FA 9 Fine Cyclo - FA Version F3C-A mit Abtriebswelle, Kegelrollenlagerung und Gehäuse .. 6 Baugrößen .. Übersetzungen einstufig 29, 59, 89, 119, 179 .. Nennabtriebsdrehmomente bis 5.140 Nm .. Beschleunigungsdrehmomente bis 7.610 Nm .. Antriebsdrehzahlen bis 6.150 min-1 .. LOST MOTION < 1 arcmin möglich .. Motorverbindung mittels Zwischenflansch .. Anbau von Motoren ohne Paßfeder mittels Klemmringdesign möglich .. als Option mit verzahnter Abtriebswelle Tab. 4 149 349 668 1390 2570 3900 - 29 29 29 29 29 59 59 59 59 59 59 89 89 89 89 89 89 - 119 119 119 119 119 - - - 179 179 - F3CA 15 G A 25...

Open the catalog to page 10

10 Fine Cyclo - FA 1 Zero backlash The CYCLO system is assembled without clearance and therefore without mechanical backlash. 2 Reduced Lost Motion For all sizes and reduction ratios: Standard<2 arcmin, upon request<1 arcmin. 3 High stiffness For example version FC-A 75 G: up to 1100 Nm/arcmin. 4 Low vibrations Three cycloid discs each displaced by 120° provide optimum load distribution and smooth running in either direction of rotation. 5 Low mass moment of inertia Since the mass moment of inertia is very low, the gearboxes respond quickly to acceleration, deceleration and reversing...

Open the catalog to page 11

FA Fine Cyclo - FA removal of load entlasten Hysteresis loss Positioning accuracy Hystereseverlust Positioniergenauigkeit distorsion angle Verdrehwinkel backlash Spiel (Nm) torque Drehmoment application of load belasten Typical Hysteresis curve for a conventional gearbox. B - 3% + 3% T2N T2N [Nm] torque lost motion Distorsionangle Typische Hysteresekurve eines herkömmlichen Getriebes. Fig. 5 Fig. 6 11 Typical Hysteresis curve for a FINE CYCLO unit. Typische Hysteresekurve eines FINE CYCLO Getriebes. of von Verdrehwinkel

Open the catalog to page 12

12 Fine Cyclo - FA 100 90 80 70 0 1000 ç (%) 2000 3000 n 1 (min-1) i = 59 i = 89 i = 119 100% 100% 90% 80% 50% ç% T T2N % Fig. 7 Typical Efficiency Curves Relative to Speed and Ratio Fig. 8 Compensation factor for efficiency Compensation Factor Load/Rated Torque ç = efficiency T = output torque T2N = rated output torque ç = efficiency n1 = input speed i = reduction ratio Abb. 7 Wirkungsgrad in Abhängigkeit von Drehzahl und Übersetzung Abb. 8 Kompensationsfaktor für Wirkungsgrad Kompensationsfaktor Last-/Nenndrehmoment ç = Wirkungsgrad T = Abtriebsdrehmoment T2N = Nennabtriebsdrehmoment ç =...

Open the catalog to page 13All SUMITOMO (SHI) Cyclo Drive Germany GmbH catalogs and technical brochures

-

Paramax 9000 series

281 Pages

-

Helical Shaft Mount (HSM)

58 Pages

-

Bevel Buddybox 4

60 Pages

-

SERVO 6000

38 Pages

-

Motion Control DrivesE CYCLO

28 Pages

-

BEVEL BUDDYBOX 4

248 Pages

-

Cyclo® BBB5

270 Pages

-

Fine Cyclo®

123 Pages

-

PARAMAX ® 9000 Series

281 Pages

-

Fine Cyclo UA Brochure

2 Pages

-

Fine Cyclo Flyer

2 Pages

-

Precision Drives Product Catalog

20 Pages

-

Fine Cyclo F4CF – UA 25

2 Pages

-

Fine Cyclo F4CFS–UA 115

4 Pages

-

Fine Cyclo F4C–C 25

4 Pages

-

Paramax 9000

352 Pages

-

Neo Hyponic

120 Pages

-

Servo 100

58 Pages

-

Servo 6000 series

6 Pages

-

Cyclo® Drive 6000

139 Pages

-

Paramax® 9000

352 Pages

-

HSM series

58 Pages

-

Astero series

186 Pages

-

IB Series catalogues

94 Pages

-

Servo Planetary Gears EPG

6 Pages

-

Servo-Planetary Gears

4 Pages

-

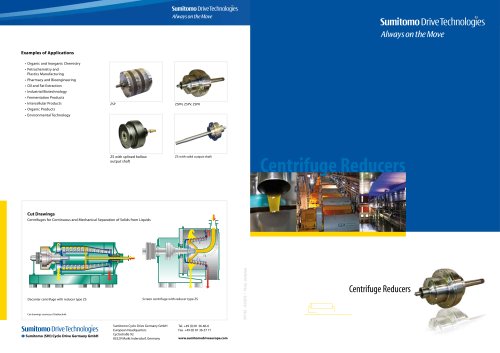

Centrifuge reducers

2 Pages

Archived catalogs

-

Product overview

16 Pages