Catalog excerpts

Bevel Buddybox 4 Gear and Gearmotor Operating Manual

Open the catalog to page 1

Table of Contents Important Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 General Notes . . . . . . . . . . . . . . . . . . . . . . . . . 2 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Important Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Safety instructions for use in an ATEX area . . . . . . . 3 Notes on transport . . . . . . . . . . . . . . . . . . . . . . 3 Important Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Inspection Upon...

Open the catalog to page 2

Important Notes General Notes Please make sure that you heed the safety notes in this documentation. Electrical hazards Using the machine incorrectly may lead to bodily injury, serious injuries and/or life-threatening situations. Hazard Using the machine incorrectly may lead to bodily injury, serious injuries and/or life-threatening situations. Dangerous situation Slight injury may result. Harmful situation Damage to the drive or the environment could be caused. Helpful information Disposal Please obey the regulations in force. Important information on ATEX explosion protection Spare parts...

Open the catalog to page 3

Important Notes Safety notes Before working on the machine (assembling, operating, maintaining, inspecting etc.), please read these operating instructions through carefully so that you know exactly how to operate the gearbox properly, you know the safety regulations to be applied and the warnings to be heeded. Keep these instructions near by the machine so that you can refer to them at any time if necessary. Transport, installation, lubrication, operation, maintenance and inspections should only be carried out by properly trained technicians, otherwise injury or damage to the machine may...

Open the catalog to page 4

Important Notes Make sure that when fitting the gearbox there is no explosive atmosphere, oils, acids, gases, vapours or radiation. Check whether the ambient temperature is within the range of application in accordance with section Installation Notes. Ensure that there is enough ventilation to the gear and there is no external heat source (e. g. from couplings). The cooling air must not exceed a temperature of 40°C. Check that the configuration matches the configuration specified on the gear's model plate. Please note: The design may only be changed after prior consultation with Sumitomo,...

Open the catalog to page 5

Important Notes Inspection Upon Delivery Lubrication Inspection • In order to avoid injury, ensure that the unit is in a stable position before unpacking. • Verify that the unit received matches your order. Using the incorrect product may cause equipment damage or personal injury. • Do not remove the nameplate from the unit. Upon delivery, inspect the unit for damage that may have occurred during shipment. Notify the shipping company immediately if you find any damage. Do not install or operate a damaged unit. • Oil lubricated units are shipped without oil, unless the customer specified...

Open the catalog to page 6

Nomenclature Nomenclature Our nomenclature details specific information about our products. Verify that the nomenclature of the unit delivered matches your order. Mounting Style Output Shaft Orientation Type Horizontal Vertical Vertical Up (Solid Shaft) Type Shaft Mount (Hollow Shaft) Flange (Solid Shaft) Foot (Solid Shaft) Input Connection Type of Input Gearmotor Free Input Shaft w/ Input Adaptor w/Quill Adaptor Reducer Gearmotor Prefix Prefix M J X Modification Type Unit built with special mods Shrink Disc No special mods applied Motor Power (applies only to 1450 RPM) Motor Power Frame...

Open the catalog to page 7

Nomenclature, continued Nominal and Exact Ratio Output Shaft Direction (shafted model only) Projects to Left Side Projects to Right Side Projects to Both Left/Right Sides Mounting Positions Nomenclature Example: LHYMS-6-4A125-EY1-B-28 L - Bevel Buddybox H - Horizontal Y - Shaft Mount (Hollow Shaft) M - Gearmotor S - Special Modifications 6 - 4 kW Motor, 1450 RPM 4A125 - Frame Size E - Metric Shaft Specification Y1 - Mounting Position B - Brake (gearmotor only) 28 - Ratio Frame Size Frame Size

Open the catalog to page 8

Storing and Transporting Storage Location • Store the unit in a clean, dry area. • Do not store outdoors or in an area with high humidity, dust, sudden temperature changes, or corrosive gases. Generally, the BBB4 gearbox is to be stored indoors, in an ordinary factory or a warehouse. The unit should be sealed, wrapped in plastic and additionally packed with desiccant. Desiccant should be replaced periodically to keep the inside of the box dry. Use of color changing desiccant will aid in identifying when desiccant should be changed. Storage Period • Do not store the unit for longer than 3...

Open the catalog to page 9

Installation Notes Installation Precautions • Do not use the reducer/gearmotor for specifications other than those shown on the nameplate or in the manufacturing specification documents. Personal injury and/or equipment damage may occur. • Do not place combustible material on or around the unit; fire may occur. • Do not place any objects around the unit that will prohibit proper ventilation. Inadequate ventilation may lead to high unit temperature and/or fire. • Do not step on or hang from the unit. Excessive weight may cause component breakage leading to personal injury and/or equipment...

Open the catalog to page 10

Installation onto Driven Shaft Taper-Grip Bushing Taper-Grip Bushing Introduction The keyless Taper-Grip bushing system provides a simple and reliable shaft attachment for Sumitomo speed reducers and gearmotors. This system allows bi-directional shaft rotation operation with a powerful, slip-free grip. To assure peak performance of your equipment, please read, understand and follow these installation instructions. Prior to installation of the BBB4 onto the driven shaft, ensure that the shaft length meets or exceeds the minimum shaft engagement value “TT” detailed in Table 1. Do not operate...

Open the catalog to page 11

Installation onto Driven Shaft, continued Taper-Grip Bushing 2 Loosen socket head cap screws. 3 Remove (unscrew) Taper-Grip bushing from the unit. 4 Clean Driven Shaft Clean all grease, oil and/or anti-seize paste from the driven shaft. Failure to do so could result in damage to shaft. Slide Taper-Grip bushing onto driven shaft. 5 Inspect and test Taper-Grip bushing on shaft. • Check shaft for burrs, corrosion, or warpage. Repair or replace shaft as necessary. • Slide bushing back and forth along shaft, checking for surface irregularities and fit. • Verify bushing is sized correctly for the...

Open the catalog to page 12All SUMITOMO (SHI) Cyclo Drive Germany GmbH catalogs and technical brochures

-

Paramax 9000 series

281 Pages

-

Helical Shaft Mount (HSM)

58 Pages

-

SERVO 6000

38 Pages

-

Motion Control DrivesE CYCLO

28 Pages

-

BEVEL BUDDYBOX 4

248 Pages

-

Cyclo® BBB5

270 Pages

-

Fine Cyclo®

123 Pages

-

PARAMAX ® 9000 Series

281 Pages

-

Fine Cyclo UA Brochure

2 Pages

-

Fine Cyclo Flyer

2 Pages

-

Precision Drives Product Catalog

20 Pages

-

Fine Cyclo F4CF – UA 25

2 Pages

-

Fine Cyclo F4CFS–UA 115

4 Pages

-

Fine Cyclo F4C–C 25

4 Pages

-

Paramax 9000

352 Pages

-

Neo Hyponic

120 Pages

-

Servo 100

58 Pages

-

Servo 6000 series

6 Pages

-

Cyclo® Drive 6000

139 Pages

-

Paramax® 9000

352 Pages

-

HSM series

58 Pages

-

Astero series

186 Pages

-

IB Series catalogues

94 Pages

-

Servo Planetary Gears EPG

6 Pages

-

Servo-Planetary Gears

4 Pages

-

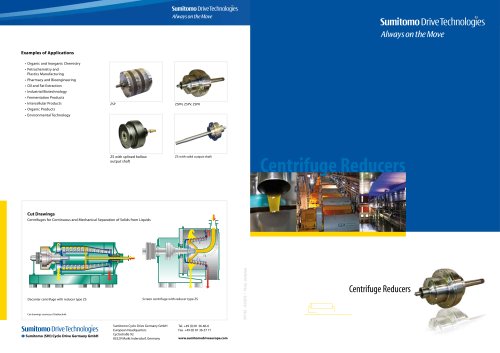

Centrifuge reducers

2 Pages

-

Fine Cyclo®

114 Pages

Archived catalogs

-

Product overview

16 Pages