Catalog excerpts

Refrigerated Compressed Air Dryers 5-6,000 scfm .14-170 m3/min Ⅲ Refrigerated Non-Cycling Ⅲ Refrigerated Cycling Ⅲ Refrigerated High Temperature

Open the catalog to page 1

Sullair Capabilities products are known around the world for their universally applicable design, outstanding craftsmanship and superior quality. Sullair Leadership Since 1965, Sullair has been recognized around the world as an innovator and a leader in rotary screw compression and vacuum technology. For more than 40 years, Sullair has designed and manufactured its own rotors and air end assemblies at the corporate headquarters in Michigan City, Indiana. The award-winning rotary screw design sets the industry standards and delivers the quality and reliability one expects from a leader....

Open the catalog to page 2

The Importance of Clean, Dry Compressed Air How much water is too much? Any amount of water is too much. Water jeopardizes everything you want your compressed air system to do. It ruins product and fouls processes. • Relative humidity is the amount of water vapor in air relative to what it could hold at a given temperature • Moisture in compressed air remains in a vapor state through the compression cycle, so it is not a problem until it leaves the compressor Liquid remaining after the aftercooler: 14.7 gallons (32%) • Air discharged from a compressor is approximately 150°F to 450°F • At...

Open the catalog to page 3

Features of the Sullair Refrigerated Dryers Refrigerated Non-Cycling Dryers RN Series: 5-325 scfm Refrigerated Digital Cycling Dryers RD Series: 400-6,000 scfm • Optimum dew point levels for the highest system performance • Cycling control for increased energy savings • Energy efficient scroll compressor • Low operating cost • Optional communication package • Consistent dew point No dew point swings Compact footprint Variable flow capacity from 10% to 100% High inlet temperature (up to 150°F) Counter-current, variable flow heat exchanger Non-velocity sensitive demister/separator Consistent...

Open the catalog to page 4

How the Energy Saving 3-in-1 Heat Exchanger Works I Warm air enters the Air to Air Heat Air to Refrigerant Heat Exchanger Exchanger and exchanges heat with the cooler air leaving. Air-to-Air Heat Exchanger I The air proceeds to the Dryer Section and is cooled using either mechanical refrigeration or liquid to a designated dew point. Refrigerant Outlet I The mixture of cold air and moisture enters the separation chamber. The moisture condenses into liquid and is isolated from the air stream and is dispensed with a timer drain. Air Outlet Refrigerant Inlet I The dry air then proceeds back...

Open the catalog to page 5

Comprehensive Controls Advanced, User-Friendly Microprocessor Controls Models RC-400, RD-400 and larger dryers include: • Digital multi-functional display • Digital dew point temperature read-out for an accurate indication of actual working conditions • Multiple alarm safety with easy-to-understand coded messages • Extensive programmability allows system to be personalized to individual user needs • Status reports for quick reference to dryer operation • Indicator to optimize preventive maintenance • Volt-free alarm contact offers a remote status signal • The controller has 8 temperature...

Open the catalog to page 6

Intelligent Integral Zero-Loss Drain The condensate drain is one of the most important components All refrigerated dryers come standard with a high quality timer drain. A truly unique zero loss drain is offered as an option. With the zero loss drain, condensate is collected in a chamber, segregated from the air flow. As condensate builds, it activates a drain level sensor built into the chamber. This opens an external solenoid valve to evacuate the condensate, closing the valve again before any air escapes. The drain cycle continually adjusts itself to working conditions. R-134a...

Open the catalog to page 7

Specifications: RN Non-Cycling Models 60Hz Motor Frequency Model 50Hz Motor Frequency Model Inlet–Outlet Connection Inlet–Outlet Connection Correction Factors for Models RN and RD Inlet Pressure psig bar Factor Pressure: F1* Ambient Temperature °F °C Factor Ambient: F3* Inlet Temperature °F °C Factor Inlet: F2* Performance Data Based On: Ambient temperature Inlet temperature Inlet pressure For flow rates at other conditions, please contact Sullair for correct sizing. *Flow Correction Factors Capacity correction to be used when operating conditions differ from those shown above. To obtain...

Open the catalog to page 8

Specifications: RD Digital Cycling Models 60Hz Motor Frequency Model 50Hz Motor Frequency Model Inlet–Outlet Connection Inlet–Outlet Connection

Open the catalog to page 9

Specifications: RC Cycling Models

Open the catalog to page 10

Specifications: RH High Temperature Models 60Hz Motor Frequency Model Inlet Temperature Correction Factor for RH Models °F 90 100 150 °C 32 38 65 Factor Inlet: F2* 1.30 1.27 1.06 Dew Point Correction Factor for RH Models °F 38 °C 3.3 Factor Dew Point: F4* 0.65 Air Quality Standards ISO 8573.1 Classes Particle (micron) size of some common substances. Eye Sight Threshold (40 micron) Fumes Tobacco Smoke Smog Oil Aerosols Ash Solid Particle Maximum number of particles per m3 General Purpose Protection Air quality to ISO 8573.1 Quality Class 1.-.5 Oil-Free Air Air quality to ISO 8573.1 Quality...

Open the catalog to page 11

Sullair’s Compressed Air Products www.sullair.com Fundamental to Sullair’s leadership is a dedication to reduce not only the amount of natural resources consumed to create energy, but to minimize environmental impact, in both the manufacture and use of all our products. We are constantly exploring new ideas and seeking new technologies to meet the ever-increasing need for high quality, energy-efficient compressed air products and environmental sustainability. © Copyright 2013 Sullair. All rights reserved. The color green is a registered trademark of Sullair. Specifications subject to change...

Open the catalog to page 12All SULLAIR catalogs and technical brochures

-

AWF® All Weather Fluid

2 Pages

-

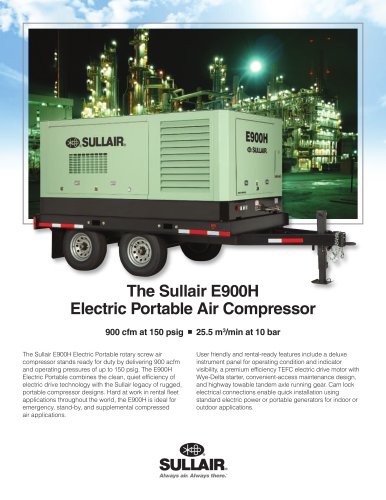

The SULLAIR 900H

2 Pages

-

Sullair SRF 1/4000®

2 Pages

-

Pristine FG™

2 Pages

-

SULLAIR Two-stage

12 Pages

-

The SULLAIR 425H

2 Pages

-

The Sullair 1600

2 Pages

-

The SULLAIR 375HH

2 Pages

-

900XHH/1150XH

2 Pages

-

ES-6 S-energy

8 Pages

-

S-energy

8 Pages

-

SULLAIR Air Treatment

19 Pages

-

LS Series

20 Pages

-

The Sullair 1300H

2 Pages

-

Sullair 260 Series

4 Pages

-

The Sullair 375H

2 Pages

-

MBT-6 Backfill Tamper

16 Pages

-

Air Audits

2 Pages

-

OFS series

8 Pages

-

SULLAIR FD1550

4 Pages

-

SRL series

8 Pages

-

DSP series

8 Pages

-

Sullair SRF 1/4000

2 Pages

-

SULLAIR Single-stage

8 Pages

-

Centrifugal compressors

12 Pages

-

Flowlogic

8 Pages

-

S-energy

16 Pages

-

S energy

16 Pages

-

900XHH-1150XHDL

2 Pages

-

Heat Recovery—S-energy® EES

8 Pages

-

Sullair Vacuum System

8 Pages

-

1150XHH/1350XHDL

2 Pages

-

750XHH/900XHDL

2 Pages

-

TSR-20

2 Pages

-

TSR-32

2 Pages

-

DR-13

2 Pages

-

Desiccant Regenerative Dryers

12 Pages

-

DR13

2 Pages

-

DE18

2 Pages

-

TSR20

2 Pages

-

RDHL

2 Pages

-

SSL10

16 Pages

Archived catalogs

-

2016 ShopTek

4 Pages

-

ShopTek

8 Pages

-

SULLAIR Air Treatment

30 Pages