Catalog excerpts

The new ultra class for Automated Guided Vehicles ilTrack Machines & Handling

Open the catalog to page 1

Due to these outstanding features and the extreme areas of applications, we call our AGV Ultra-Track or uTrack. Hltra strong 5-200 t Max, load transport Qltra compact 260 mm Min, vehicle height Qltra available 99,8 % Production reliability

Open the catalog to page 2

Itra strong Reliable and safe transport of products up to 200 t uTrack is the heavy-duty AGV for automated material transport from 5 to 200 t: Due to the uTrack track guidance, even extremely long and wide loads can be moved safely. High load capacities can be realized regardless of the ground quality. Even large weight differences or the relocation of the material center of gravity have no effect on the positioning accuracy.

Open the catalog to page 3

Itra precise Positioning and fleet repeat accuracy up to ±0.3 mm The track guidance enables high-precision positioning and repeatability - consistently across the entire vehicle fleet, This unique feature enables optimal integration into automated processes and precise interaction with robots or machines, This reduces commissioning to a minimum, The uTrack track guidance eliminates lateral deviations, height tolerances or angular errors of the front

Open the catalog to page 4

The lean system with low operating costs The lean design and the use of energy-efficient components make the uTrack system particularly economical and sustainable. Due to the minimal rolling resistance between the steel wheel and the steel rail, only low drive power is required to move large loads. Unlike conventional AGVs, there are no ruts in the production line and hall transitions or floor joints remain intact. Stable Communication 5GHz WLAN Reliable safety technology 2 x 270° laser scanners Robust navigation RFID technology Efficient energy supply Contactless transmission with high...

Open the catalog to page 5

Itra compact The flattest AGV system in its performance class with a total height of 260 mm The uTrack track guiding system offers extremely high payload in an extremely small space, The result is an ultra-compact AGV with a low total height, Only 260 mm for an AGV with a capacity of up to 40 t, uTrack improves the ergonomic situation for work at and on the transported product, offering plenty of space around the AGV and making it possible to climb on and off the cart without any additional aids, ltra available Minimized downtimes through maximized production reliability uTrack is the...

Open the catalog to page 6

mTrack application areas: The AGV for large and heavy products in pre- and final assembly The optimal application for the uTrack system is the transport of heavy products from 5 - 200 t in the area of pre- and final assembly. Application examples: Commercial vehicles, Construction and agricultural machinery, Aircraft industry and Manufacturing systems. uTrack advantages in pre- and final assembly: Agriculture, Construction industry and Automotive ■ reliable transport of heavy and large-volume loads ■ highest safety for persons and objects ■ high availability ■ low operating costs ■...

Open the catalog to page 7

uTrack application areas: AGV interaction with high requirements on position and repeat accuracy Complete integration into the safety concept of the overall plant Due to the very high repeatability of the uTrack system, interactions with other machines and complex systems can be realized with the highest precision. Application examples: Machining centers, Welding and riveting robots, Stacking stations and Lifting tables. Various additional functions such as rotating the swiveling are possible Interaction with various robot types Joining (top) Accurate positioning and repeatability is...

Open the catalog to page 8

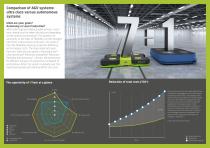

Comparison of AGV systems: ultra class versus autonomous systems What are your goals? Autonomy or Lean Production? When selecting automated guided vehicles, numerous criteria must be taken into account depending on the production processes. The question of autonomy or the topic of flexibility is often brought into focus in discussions with users. Too much or too little flexibility reduces production efficiency and increases costs. The more important questions are: What are your goals in the production? Lean processes? Maximum availability? Maximum flexibility and autonomy? uTrack is the...

Open the catalog to page 9

Cross chassis in the trolley or turning stations integrated in the floor allow the uTrack transport trolleys to change direction easily. This makes it possible to reach any position on the job site. dTrack transport carts: Variable chassis design Agricultural machinery assembly: Load capacity 23 t L= 3500 mm B= 2000 mm H=220 mm Agricultural machinery assembly: Load capacity 16 t L= 7500 mm B= 2800 mm H= 400 mm Transport of turbine components Load capacity 85 t L= 3010 mm B= 2850 mm H= 440 mm Assembly of milling or machine tools Load capacity 10 t L= 3810 mm B= 1540 mm H= 150 mm Cross-type...

Open the catalog to page 10

Autonomous and free or better ultra lean and ultra efficient? Contact our uTrack experts: +49 5207 9122 265 | sales@strothmann.com Test drive now: www.ultra-track.com Headquarters STROTHMANN Machines & Handling GmbH Altenkamp 11 33758 Schloß Holte-Stukenbrock Germany Phone: +49 5207 9122 0 E-mail: info@strothmann.com Global presence Australia, New Zealand Siempelkamp Pty. Ltd. +61 3 9596 7577 thiago.k@siempelkamp.com.au Brazil Siempelkamp do Brasil Ltda. +55 41 3232 6806 frederico.marques@siempelkamp.com China Strothmann Machines & Handling Trade (Shanghai) Co. Ltd. shanghai@strothmann.com...

Open the catalog to page 11All Strothmann Machines & Handling GmbH catalogs and technical brochures

-

FeederPlus6neo

2 Pages

-

Line gantries

7 Pages

-

RoundTrack

13 Pages

-

LeanTrack

7 Pages