Catalog excerpts

Stromag Dessau safety in motion BZFM V7

Open the catalog to page 1

Electromagnetic Spring Applied Brake Protection IP 44 BZFM V7 Stromag Dessau safety in motion Applications Brake series for mounting to standard electric motors as general industrial brake. Standard Features Coil Body with coil thermal class 155 (F), special surface protection Friction lining carrier Rigidly fixed on motor shaft via fitting key, zinc coated Friction Lining Axially flexible friction pads in the friction lining carrier allow a high tolerance when fixing friction lining carrier on the shaft thus simplifying the mounting on brake assembly Adjusting Ring a simple reduction of...

Open the catalog to page 2

Electromagnetic Spring Applied Brake Protection IP 44 BZFM V7 Stromag Dessau safety in motion Advantages Torque range 2,7 -380 Nm. Simple assembly to motor, no dismantling of brake required. Completely pre-mounted and adjusted. All surfaces are corrosion resistant. Compact, simple construction with high heat capacity. The fitted friction pads form an interrupted friction face thus resulting in good air circulation and heat dissipation. Less wear due to high stability of the friction material. Delivered in run-in and torque tested condition. Simple torque adjustment with adjusting ring. As a...

Open the catalog to page 3

Electromagnetic Spring Applied Brake Protection IP 44 BZFM V7 Stromag Dessau safety in motion Designation of individual components 01 06 05 07 12 04 13 02 03 14 01 02 03 04 05 06 07 12 13 14 Coil body Armature disc Brake disc (counter friction face) Friction lining carrier Friction lining Coil Spring Adjusting ring Seal ring Rubber collar Brake operation The brake BZFM V7 is a spring loaded electromagnetic double-face brake which brakes without current and is released electromagnetically. The coil body (01) contains a coil (06) which is potted with an synthetic resin compound in accordance...

Open the catalog to page 4

Electromagnetic Spring Applied Brake Protection IP 44 BZFM V7 Stromag Dessau safety in motion If the coil (06) is connected to a direct voltage as specified on the identification plate or about a Stromag rectifier set to a alternating voltage, the magnetic force will draw the armature disc (02) to the coil body (01) against the spring pressure (07). The friction lining is released, the braking is cancelled and the brake is released. Micro Switch standard option available from size 6,3 up to 25, Inboard Proving Switch, one common contact, one normally open contact and one normally closed...

Open the catalog to page 5

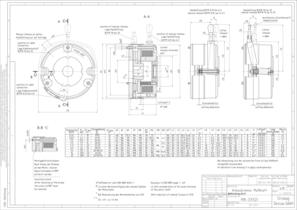

manual release BZFM 0.25 up to 6.3 manual release BZFM 10 up to 25 Manual release as option Lage KabelanschluR position of manual release Lage Handluftung leverfloosly attached part) setting dimension setting dimension Nach Anbau der Bremse entfernt werden Bei Abweichung von der skizzierten Form ist das MaRblatt sinngemaR anzuwenden! At deviation from drawing it is apply synonymously! mounting srews! After mounting of the brake 1) Pafifedernut nach DIN 6885 Blatt 1 2) L2 unter Berikksichtigung des axialen Spieles L2 with consideration of the axial interplay With reduction of nominal torque...

Open the catalog to page 6

Electromagnetic Spring Applied Brake Protection IP 44 Stromag Dessau BZFM V7 safety in motion Calculations Full Load Torque Load torque Torque Power Constant Speed = = = = = = FLT Nm Nm kW 9550 rpm Initial Torque, size of brake = FLT x Factor (25% - 200%) Calculating Maximum Stops per Hour using Braking Tables Example: Motor J ML MSN = = = = 4 kW; 3000 rpm 2 Total inertia of Load + motor = 0,0245 kgm Load Torque = 20 Nm Brake Torque = 100% FLT 4 x 9550 3000 = kW x 9550 = rpm Motor FLT 12.7 Nm = Brake selection = BZFM 10 V7 (113 Nm) 2 = Jxn 182000 = 0,0245 x 3000 182000 = KJ per switching...

Open the catalog to page 7

Electromagnetic Spring Applied Brake Protection IP 44 BZFM V7 Stromag Dessau safety in motion Permissible Heat Capacity Switching operations per switching in relation to the number of switchings W = f(z) for n = 3000 rpm * * Switching operations W in kJ 100 10 BZFM 25 V7 1 BZFM 16 V7 BZFM 10 V7 BZFM 6,3 V7 BZFM 4 V7 BZFM 2,5 V7 BZFM 1,6 V7 BZFM 0,63 V7 BZFM 0,25 V7 0,1 1 10 100 1000 operations per hour z in h-1 * * permissible switching operations per switching at other speed ratings on request Spring Applied Brake BZFM V7 – 01.06.2009 6

Open the catalog to page 8

Electromagnetic Spring Applied Brake Protection IP 44 BZFM V7 safety in motion Our Address Stromag Dessau GmbH Dessauer Str. 10 D-06844 Dessau-Roßlau Tel.: +49 (340) 2190-203 Fax: +49 (340) 2190-201 E-Mail: vertrieb.dessau@stromag.com Internet: http://www.stromag-dessau.de Spring Applied Brake BZFM V7 – 01.06.2009 Stromag Dessau 7

Open the catalog to page 9All STROMAG catalogs and technical brochures

-

Carbon Fiber Shaft

1 Pages

-

Stromag KMS...THC

1 Pages

-

Stromag Vector Couplings

12 Pages

-

4 BZFM Brake

16 Pages

-

NFF Brake

16 Pages

-

Clutches and Brakes

8 Pages

-

brakes type 600

2 Pages

-

Lever Switches, Serie HHEV

9 Pages

-

Geared Switches, Serie HGE

24 Pages

-

Geared Switches, Serie HEG

10 Pages

-

Determination of Clutches

24 Pages

-

Spidex®, Dentex®

28 Pages

-

Periflex® VN Disc Coupling

36 Pages

-

Disc Coupling

36 Pages

-

highly-flexible ring couplings

31 Pages

-

couplings for Cardan Shaft

34 Pages

-

Stromag: safety in motion

20 Pages

-

Two-in-one 1

4 Pages

-

Two-in-one 2

4 Pages

-

Wind Turbine Catalogue

7 Pages

-

Hydrid Clutches and Brakes

8 Pages

-

High Protection Brake Catalogue

16 Pages

-

Flexible Couplings

2 Pages

-

Highly-flexible TRI-R Couplings

31 Pages

-

Highly-flexible TRI Couplings

33 Pages

-

Highly-flexible GE Couplings

28 Pages

Archived catalogs

-

Electromagnetic Tooth Clutches

36 Pages

-

Driveshaft

44 Pages