Catalog excerpts

Empower Medical Innovation E X PA N D I N G M E D I C A L P O S S I B I L I T I E S W I T H T H E W O R L D ’ S O N LY F U L L - C O L O R M U LT I - M AT E R I A L 3 D P R I N T E R

Open the catalog to page 1

Ask anyone in the medical community what their top objectives are and they’ll probably say that everything boils down to improving patient outcomes while making the healthcare system more efficient. Having the right tools to do the job is one crucial element in solving problems and becoming more effective and productive. Additive manufacturing, widely known as 3D printing, is one of those tools that has helped inventors, educators, and researchers improve how they design, manufacture, teach and perform research. The same technology has also benefitted health care providers, with tools that...

Open the catalog to page 2

The Stratasys J750 3D Printer isn’t just the latest introduction in the portfolio of PolyJet 3D Printers. It’s the first-ever full-color, multi-material system, and it addresses the needs of biomedical engineers and medical researchers who want realistic anatomical models but have to contend with inconsistent color results and less-than-lifelike textures from current 3D printing technology. It also targets rapid prototyping managers using multiple technologies and messy processes, looking for a leaner, cleaner method to create exactly what the designer needs. MEDICAL USE CASES The advent of...

Open the catalog to page 3

The following information provides a more in-depth look at Stratasys J750 features and capabilities and how it’s aptly suited for multiple medical applications. I N C R E D I B L E PA R T R E A L I S M A hallmark of the Stratasys J750 is its true, full-color capability, a breakthrough in 3D printing technology. The ability to 3D print with various colors is not new, but previous offerings forced users to sacrifice either color range or part quality. The Stratasys J750 changes this by producing smooth plastic parts with over 360,000 colors. This color range is made possible because the...

Open the catalog to page 4

The availability of such a wide color spectrum, combined with the fine-finish, multi-material capability, lets the Stratasys J750 produce parts with an incredible array of characteristics. Prototypes that need to look, feel and function like future products are possible in a single print operation, with minimal to no finishing steps like painting, sanding or assembly. U N M AT C H E D V E R S AT I L I T Y The Stratasys J750 not only delivers incredible realism but it’s also the most versatile 3D printer available. This versatility originates from its robust material capacity, accommodating...

Open the catalog to page 5

For rapid prototyping programs, this versatility is an opportunity to meet the diverse demands of your operation without the inefficiencies associated with material changes or the need to invest in, operate and maintain a variety of technologies. You can print realistic prototypes, presentation models, Digital ABS injection molds, jigs, fixtures, educational and promotional pieces, production parts – or all of the above, with one system. FA S T, E F F I C I E N T W O R K F L O W A N D E A S E O F U S E Using the printer is easy, starting with GrabCAD Print™ software, which lets you import...

Open the catalog to page 6

Some 3D printing processes must run in a dedicated facility because of the materials, chemicals and post-processing steps involved. In contrast, the Stratasys J750 3D Printer uses a clean, easy process, with no hazardous chemicals to handle, a particularly important consideration in a hospital setting. It’s compatible with soluble support material that can be removed in a solution bath. This lets users focus on other duties while the support material is being removed and also makes it easier and less problematic to clean delicate parts and internal cavities, an important feature for...

Open the catalog to page 7

For another example of how realistic modeling plays a role in advancing health care, view this video to see how the Centre for Biomedical and Technology Integration uses the Stratasys J750 to create realistic patient-specific anatomical models for physician training. A 3D printer with this capability is a powerful tool, enabling creative solutions for diverse challenges that impact the healthcare industry. In the following chapters, we’ll look at how 3D printing benefits the development and delivery of healthcare products and services and how the Stratasys J750 fits. EMPOWER MEDICAL...

Open the catalog to page 8

CHAPTER TWO IMPROVING MEDICAL OUTCOMES AND ECONOMICS As 3D printing technology evolves, its use in the medical field continues to grow. Medical device manufacturers, hospitals, doctors, medical researchers and educators can all benefit. RAPID PROTOTYPING AND PRODUCT DEVELOPMENT Rapid prototyping and product development are key areas where 3D printing helps medical device manufacturers. In-house 3D printing produces prototypes much more quickly and usually for less cost than traditional manufacturing methods, particularly when it replaces outsourcing. This speeds up the entire development...

Open the catalog to page 9

CHAPTER TWO IMPROVING MEDICAL OUTCOMES AND ECONOMICS appearance. Doctors use these models to plan the best surgical approach resulting in shorter operating times and better post-operative results. 3D printed models also help train doctors to perform medical procedures and use new devices, and educate medical students on general anatomical structures. The Stratasys J750 in particular offers complex geometries and blends of material properties that would be difficult or impossible to produce with conventional manufacturing methods. Training models can mimic the look and feel of living tissue...

Open the catalog to page 10

M A K I N G A D VA N C E M E N T S W I T H 3 D P R I N T I N G T E C H N O L O G Y Medical device manufacturers must provide the best product they can, not only to support advances in health care but also to compete in the marketplace. This typically involves a relentless pursuit of product development and improvement, which typically requires physician feedback to assess what the market wants or how to improve existing products. Designers assimilate this information and develop initial designs. Prototyping managers take this information and create prototypes, working with the designers to...

Open the catalog to page 11All Stratasys catalogs and technical brochures

-

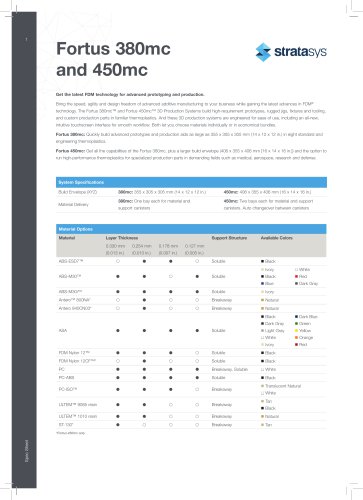

Fortus 450mc

8 Pages

-

TECH STYLE J850™

8 Pages

-

J3 DentaJet 3D printer

2 Pages

-

Neo800

2 Pages

-

TECHSTYLE

8 Pages

-

J5 MediJet™

8 Pages

-

F123 Composite-Ready

6 Pages

-

Origin One Dental

8 Pages

-

F900

8 Pages

-

Stratasys J55-Prime

8 Pages

-

FDM Materials and Systems

12 Pages

-

F123 Series Brochure

4 Pages

-

Objet 30 V.5.

1 Pages

-

F770

8 Pages

-

Origin One

8 Pages

-

Stratasys H350

8 Pages

-

Fortus 450mc - 380 mc

2 Pages

-

Objet 500 Connex 1

2 Pages

-

Objet 30 Prime

2 Pages

-

Objet 260 Connex 3

2 Pages

-

PolyJet Materials and Systems

16 Pages

-

Stratasys J4100

2 Pages

-

J700 Dental

4 Pages

-

J8 Series Brochure

8 Pages

-

J35 Pro

4 Pages

-

J720 Dental

4 Pages

-

J5 DentaJet

8 Pages

-

ABOUT 3D PRINTING

6 Pages

-

Surgical Planning

8 Pages

-

FDM Material: Nylon 12CF

2 Pages

-

3D printing for dental

4 Pages