Website:

Störi Mantel

Website:

Störi Mantel

Catalog excerpts

KP 500 OPTIM Optimization cross-cut saw Automatic material cross-cutting technology

Open the catalog to page 1

Optimization saw, which fulfills the specified objectives Optimization saw KP 500 Optim reacts to all needs of customers from various fields. It is suitable for cross-cutting for all industrial requirements. Choose from our comprehensive line of simple to fully automated solutions. The KP 500 Optim line offers an innovative solution for cross cuts from the Störi Mantel specialists in combination with the most modern control technology and software. The firm and robust structure of the optimization saw ensures precise and fast wood cross cuts. The feeding mechanism moves the cut material to...

Open the catalog to page 2

Enter the world of timber cross-cutting automation KP 500 Optim is an optimization saw for fast and precise production. The latest generation of the KP3 software control utilizes a 15“ touchscreen display. It is reliable and easy to use. Network connection is ensured by the Ethernet RJ 45 port or the possibility to transfer data using the USB port. The software makes the information about the ongoing processes always accessible on the screen or via the network, without the need to suspend the production process. The display allows for an easy and comfortable machine control. Individual...

Open the catalog to page 3

Loader system (Fig. 1) (of the pressing mechanism at the work table input) moves along a precise linear rail and bearings and, together with the pneumatic clamp (Option) at the end of the pressing mechanism, ensures very precise positioning of the workpiece at the cutting line (±01 mm*). The workspace in front of the machine allows the operators to comfortably sort and prepare more material that can then be inserted in the given order for cross cutting; it thus eliminates time delays related Finger thrust (Option) (Fig. 2) Detail of the cutting area with an intelligent finger thrust, which...

Open the catalog to page 4

Optimization cross-cut saw KP 500 Optim supports a range of applications The functions of the optimization software include a wide range of available cutting programs and their combinations, thus ensuring that the machine is, from this perspective, very universal and prepared to react to various customer needs. The system can be amended by various optional accessories, the so-called option, such as sorting mechanisms passed the cut, laser printers or label printers for a fast location of the necessary order. Optimalization Waste optimalization One of the machine advantages is its ability to...

Open the catalog to page 5

By all means adjusted to your requirements When you process a big volume of timber and when you need to be flexible when executing your orders and to have a high cutting output and safe operation, this saw will be your effective assistant with a quick return of your initial investment. The modular solution offers a perfect adaptation to your needs, thus providing you with a future flexibility for your further expansion. Higher productivity automatic material sorting Thanks to an effective structure of the KP 500 Optim saw, the basic machine can be furnished with automatic sorting. This way...

Open the catalog to page 6

Optimization cross-cutting saw KP 500 allows for a wide range of applications Some advantages of the machine include a simple operation, high speed and accuracy of individual cuts and a high degree of flexibility of the input and output dimensions of the processed material. KP 500 OPTIM / high operational reliability / user friendly / comfortable replacement of the saw blade / easy and intuitive control / ergonomically placed controls / large 15“ touchscreen display / support for cut combinations / excellent safety / left as well as right design from the perspective of the machine operator

Open the catalog to page 7

Technical data Optimization cross-cutting saw KP 500 Optim The table lists the main technical attributes of the device. For more detailed information please contact a STÖRI MANTEL technician. STANDARD Length of cut material Material width 3 200–6 200 mm pursuant to the cutting diagram (see the web) Saw blade Ø 500 mm [max. cutting height) Instrument feed speed Blade lift height SAW BLADE Outer Ø of the saw blade Inner Ø of the saw blade anchoring hole Allowed revolutions of the blade Saw blade only available in SK version LOADING MECHANISM Driving unit Linear feed within an enclosed profile...

Open the catalog to page 8

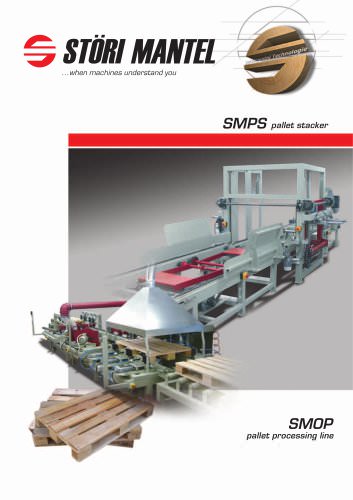

STÖRI MANTEL ...when machines understand you The company’s aims are currently not only to develop a single specific machine with unique technical properties, but a unified and modular pallet production technology system for customers. What does STÖRI MANTEL mean to our customers? / many years of tradition in the area of wood processing technology and engineering / high-quality work on every single machine, while respecting traditions and innovations, is ensured by our specialists with many years of experience / patented solutions / our own service with the delivery of spare parts We strive...

Open the catalog to page 9

We are the right choice, when you need: Make production more efficient Reduce the workforce needed Save costs Do not hesitate to contact us! Ing. Pavel Vokatý tel.: +420 607 104 014 e-mail: p.vokaty@stoerimantel.com STÖRI MANTEL s.r.o. U Trati 2620 (Tesla industrial area) 756 61 Rožnov pod Radhoštěm Czech Republic Störi Mantel

Open the catalog to page 10All Störi Mantel catalogs and technical brochures

-

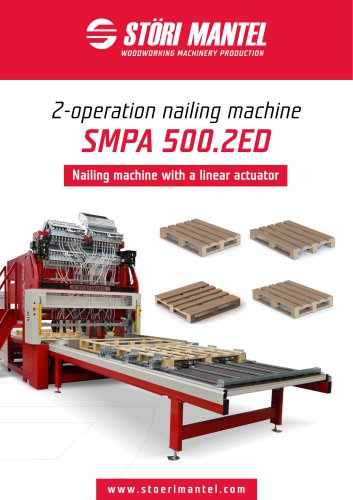

Nailing machine SMPA 500.2ED

10 Pages

-

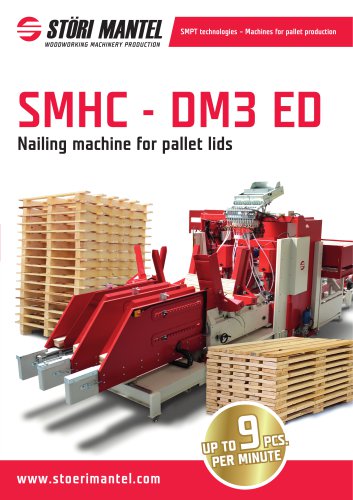

Dynamic Machine DM1

2 Pages

-

Dynamic Machine DM2

2 Pages

-

FLS ARROW I Single-blade ripsaw

11 Pages

-

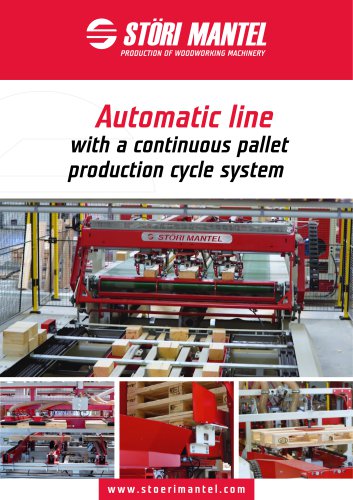

Tandem Line (High capacity)

6 Pages

-

Company Catalog

40 Pages

Archived catalogs

-

FLS 120/160 ECO

2 Pages