Website:

Störi Mantel

Website:

Störi Mantel

Catalog excerpts

PRODUCTION OF WOOD MACHINING TECHNOLOGY Single-blade ripsaw

Open the catalog to page 1

Ripsaw that meets the specified objectives / secured safety / more economical production / higher yield The cut material, freely laid on a workbench, is cut in the longitudinal direction by a sliding saw blade. The laser beam exactly shows the path of the given cut. Once the cut is finished, the saw blade retracts below the workbench of the saw and moves to the initial position. The rear longitudinal stopper moves the cut material to a new value of the cut width. The ripsaw is optimal for longitudinal formatting. It is suitable for the universal cutting of massive wood and all planar...

Open the catalog to page 2

The FLS ARROW I can be used for cutting prisms, squared timber, planks, boards as well as large-area material. The input material can be edged, ripped and formatted, and cuts and laths can be made. An advantage is the possibility to make skew or bevelled cuts. The machine can be also used for splitting non-wooden materials, such as PUR/PIR panels, plastic materials, sandwich panels, cement-chip panels or for the production of batten boards. An advantage of the machine is its simple operation, high speed and accuracy of individual cuts with a high degree of flexibility of the input and...

Open the catalog to page 3

Single-blade ripsaw FLS ARROW I The ripsaw offers a wide range of cutting options. However, saving a worker and more effective material yield is especially important. / possibility to regulate the blade feed speed in the cut, 0-80 m/min - guarantees a high cutting performance / blade lift regulation - ensures a clean cut and a high quality of the cut surface Safety elements that ensure the ripsaw occupational safety are a matter of course. The machine meets the strict occupational safety requirements arising from the corresponding EC directives and regulations. 1/ Second station (option)...

Open the catalog to page 4

Innovative solution, which you can depend on 1/ Unique solution of the saw travel A perfect concept of the travel of the floating saw aggregate. The saw carriage is furnished with loadbearing and guidance rollers, which ensure optimal guidance of the floating aggregate during the cut. From the technological perspective, the coldmilled guidance rods have the highest added value due to their extraordinary stability and homogeneity. This innovative solution allows for a perfect and accurate guidance of the saw aggregate without any unnecessary vibrations. 2/ Precise guidance of the rear...

Open the catalog to page 5

Efficient options: Adjusted to your applications in all aspects 1/ Universal solution By a machine combination of the FLS Arrow I + UKS shortening saws, you can create a universal node for transverse and longitudinal material splitting, which is a solution for a single operator. This concept creates an efficient solution by saving space and increasing productivity. The machine length and arrangement will comply with your requirements. 2/ Cursory column suspension (Option) The cursory column suspension has been designed for customers who use the machine in a line of other machines and who...

Open the catalog to page 6

FLS ARROW I allows for a wide range of applications The ripsaw allows not only for longitudinal, transverse and skew cuts, it also allows for bevelled cuts, packet cutting, ripping large-area materials, cement-chip panels or sandwich panels with steel reinforcement. If you do not process large volumes of material, but need to be flexible during the implementation of your orders and need a ripsaw with a high cutting performance and safe operation, this saw represents an efficient tool with a high economic return. Dividing rough cuts Longitudinal cuts (ripping) Diagonal cuts and cut-outs...

Open the catalog to page 7

FLS ARROW I technical data The table presents the main technical characteristics. For more detailed information, please contact a Stori Mantel expert.

Open the catalog to page 8

Smart control, which you can depend on ABS positioning Implements an exact setup of the required distance of the stopper from the saw kerf. You can quickly change the selected width by pressing the given absolute cutting width from the table on the control panel or using the fast selection buttons. CHAIN positioning It automatically moves the rear stopper by the required width always after the given cut is performed. The value can be selected from the table of the programmed widths. The program of course takes into account the loss of the overall width + saw kerf. Do you process material,...

Open the catalog to page 9

STÖRI MANTEL ...when the machines understand you The current objective of the company is not only to develop a single particular machine with unique technical characteristics, but a system of a unified and modular solution of the pallet production technology for the customer. What does STÖRI MANTEL means for our customers? / long-term, more than 27 years of tradition in the area of wood-processing technology and machinery production / high-quality work performed on all machines with respect to the tradition as well as innovation / guaranteed high-quality services — the entire process, from...

Open the catalog to page 10

Reduce costs We are the right choice, when you need: o o o r^i Make production Save more efficient labour force STORI MANTEL PRODUCTION OF WOOD MACHINING TECHNOLOEY STORI MANTEL s.r.o. U Trati 2620 (Tesla industrial area) 756 61 Roznov pod Radhostem Czech Republic in f Stori Mantel /stoerimantel

Open the catalog to page 11All Störi Mantel catalogs and technical brochures

-

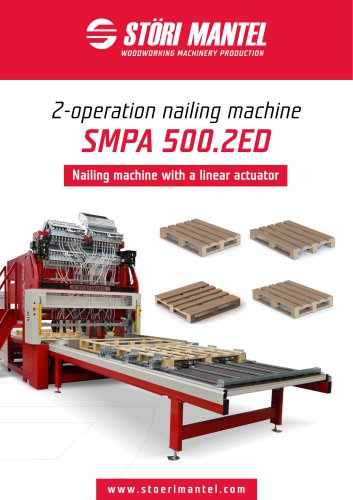

Nailing machine SMPA 500.2ED

10 Pages

-

Dynamic Machine DM1

2 Pages

-

Dynamic Machine DM2

2 Pages

-

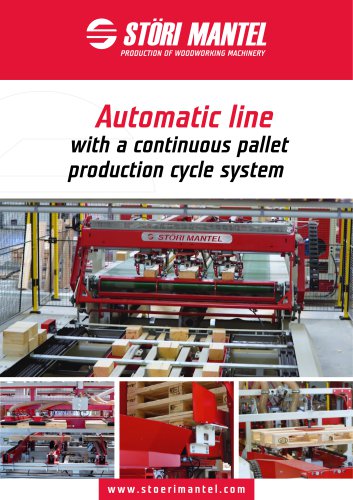

Tandem Line (High capacity)

6 Pages

-

Company Catalog

40 Pages

Archived catalogs

-

FLS 120/160 ECO

2 Pages