Website:

Störi Mantel

Website:

Störi Mantel

Catalog excerpts

PRODUCT CATALOG ...when machines understand you

Open the catalog to page 1

...when machines understand you Introduction to the company Stori Mantel s.r.o. has been on the wood machining and pallet technology market since 1995. The company’s origins date back to 1947 when Fritz Störi sen. established Störi Ent. Co., a Swiss company that originally manufactured thermoelectric technology, heat pumps and control systems for industrial companies. Its manufacturing activities subsequently expanded into producing wood machining equipment, which has been manufactured in the Czech Republic since 1995. From the very beginning at our production plant in Rožnov pod Radhoštěm,...

Open the catalog to page 2

FLS Technology - Single Blade Ripsaws FLS technology – rip saws Growing timber prices and production expenses, short delivery times, and issues related to timber material quality while maintaining the high-quality of given products is a task that all small, medium, and large-sized companies face today. Enormous savings can be achieved in this area. Every millimeter of timber saved during wood-processing activities contributes to higher profit. FLS technology represents a modern and universal way for material ripping and formatting using a single blade saw with a floating aggregate and great...

Open the catalog to page 3

FLS Technology - Single Blade Ripsaws 1./2./3./4./5./6./7./8./9. FLS technology allows not only for longitudinal, cross and angled cuts, but also for beveling, in-packet cutting, ripping large surface materials, cement -bonded particle boards, sandwich panels with steel reinforcement, etc.

Open the catalog to page 4

FLS Technology - Single Blade Ripsaws Technical data • • • • • • • • • • • • • Engine power Cut height standard Saw blade Inner ø of the saw blade Adjustable feeding speed into the cut Cut length standard Cut width standard Working height Outer dimensions Exhaust Required exhaust speed Pressurized air connection Power supply 11 kW (15 kW option), 2900 rpm 0 - 120 mm / 0 - 160 mm ø 450 to ø 500 mm/ ø 550 mm ø 80 mm 0 - 60 m/min. 2.2 m to 6.2 m 420 mm (optionally up to 1600 mm) 850 ± 50 mm Length = cut length + 1800 mm Width = 1300 mm (standard) 2 x ø 160 mm 25 - 30 m/s 0.8 MPa 400 V/3/50 Hz...

Open the catalog to page 5

FLS Technology - Single Blade Ripsaws 1. Double-precision bearings for saw carriage 2. Backstop drive system optional and designed according to the machine usage and customer requirements 3. Input chain conveyor increases labour productivity (optional) 4. Metal plates with ball rollers allow easy manipulation of heavy materials 5. Submersible rollers at the front table for transporting cut-off materials 6. Auxiliary arms for removing cut-off materials 7. Clearly structured control panel with touchscreen and dual 25 mm LED display for easy reading of absolute and chain positions 8. Overhead...

Open the catalog to page 6

FLS Technology - Single Blade Ripsaws FLS ARROW I The STORI MANTEL line includes the FLS ARROW I single blade ripsaw, allowing manufacturers to meet various demands for processing massive wood and large-area materials and optimize production capacities, with special technologies for separating plastic, thin steel profiles, and sandwich isolation panels with steel reinforcement. The basic variant of this model already has a range of technical innovations and is a generally very well received and popular product. It increases yields, work productivity, and quality of wood matter with special...

Open the catalog to page 7

FLS technology combined with cross-cutting FLS 170/210 Arrow I combined with UKS 700. The combination of lengthwise and crosswise separation of material leads to a significant increase of the yield. With respect to the dimensions of the cut material and achieved production capacity, we recommend using shortening saws with a movement system for optimum configuration of the cut diagram (optional). 8

Open the catalog to page 8

FLS Technology - Single Blade Ripsaws A completely new method for suspending the mobile unit represents a revolutionary solution for lifting the saw. This concept will also find applications in heavy sawing operations. The basic variant of this FLS machine already allows the machine to be included in technological lines, providing efficient and rational utilization of FLS technological advantages. Technical data • Engine power • Cut height standard • Saw blade • Inner ø of the saw blade • Speed feed into the cut • Cut length standard • Cut width standard • Working height • Outer dimensions...

Open the catalog to page 9

FLS Technology - Examples from practice 1. FLS with an automatic material feeder and timber pile dismantler 2. Rear material feeder 3. Large-surface material formatting 4. FLS machine operations 5. Cross-longitudinal formatting of PUR sandwich panels with steel reinforcement 6. Optional FLS ECO machine extension - Adjustable cross bench

Open the catalog to page 10

FLS Technology - Examples from practice 1. Hydraulic lifting platform for material feeding 2. Automated center for material longitudinal and cross formatting (FLS ARROW I/UKS 1000 OPTIM) 3./4. Formatting construction panels with cement cores

Open the catalog to page 11

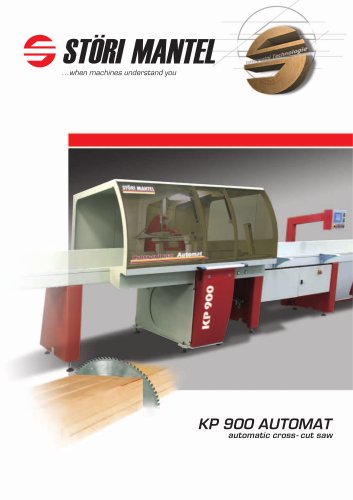

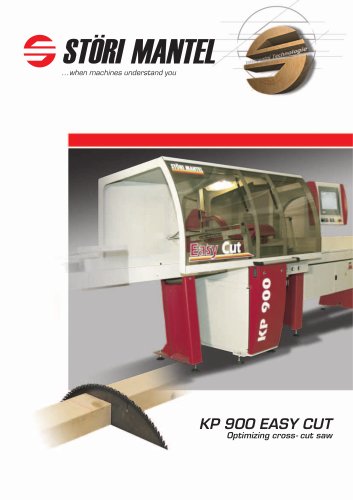

Cross-cut technology Cross-cut technology Very demanding requirements to do with material shortening are also placed on yield, flexibility, efficiency, and quality when individual production orders are implemented. Apart from required shortened delivery times, manufacturers need to fully depend on the production technology used. Material cross-cut machines represent yet another production item in our company’s portfolio suitable for small to large operations. Cross-cut saw product line: To satisfy various customer requirements and optimize its production capacities, Störi Mantel offers the...

Open the catalog to page 12

Cross-cut technology UKS 400/700/850/1000/1000 MAX The UKS 400, UKS 700, UKS 850, UKS 1000, and UKS 1000 MAX cross-cut saws are intended for shortening plastered and edged lumber as well as other materials (flakeboards, plastic, sandwich panels etc.). The machine can cut material individually or in packets. These machines find applications in furniture production, plastic separation, thin steel profiles, pipes, and sandwich isolation panels with steel reinforcement. Under-the-table shortening saws are supplied with hydraulic or pneumatic lifting of the saw and a holder for the cut material....

Open the catalog to page 13All Störi Mantel catalogs and technical brochures

-

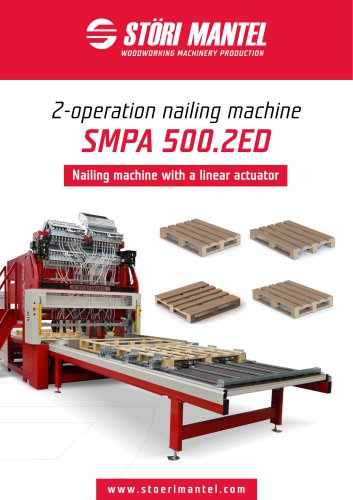

Nailing machine SMPA 500.2ED

10 Pages

-

Dynamic Machine DM1

2 Pages

-

Dynamic Machine DM2

2 Pages

-

FLS ARROW I Single-blade ripsaw

11 Pages

-

Tandem Line (High capacity)

6 Pages

Archived catalogs

-

FLS 120/160 ECO

2 Pages