Catalog excerpts

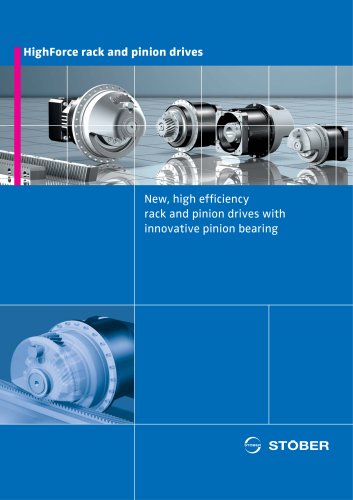

HighForce rack and pinion drives New, high efficiency rack and pinion drives with innovative pinion bearing

Open the catalog to page 1

Drive optimisation for machine tool manufacture A new compact solution for more efficiency In the past it was normal on rack and pinion drives to fit the pinion directly to a gear unit's flange shaft. As a result of this single-sided pinion mounting, the very high tilting moment had to be absorbed by the bearings in the planetary gear unit. With the result that 'over-dimensioned' gear units with an abundant 'excess of torque' were required. Rack and pinion drive ZTRS-PHA721 Cast supporting bearing cover with ribbed internal contour for highest torsional stiffness The supporting bearing...

Open the catalog to page 2

Specific rack and pinion drives as complete, rea To see an animated film on HighForce ZTRS-PH features go to mediacenter.stoeber.de With helical geared planetary gear units The ZTRS drives are based on the ServoFit® precision planetary gear units that are designed for very high requirements on torque as well as on torsional and tilting stiffness. The ratios range from i = 4 to i = 121 (up to 3 gear unit stages). ZTRS-PHA822 rack and pinion drive, two stage, with MF motor adapter Balanced FlexiAdapt® clamp coupling for large motor shaft diameter with integrated thermal length compensation ME...

Open the catalog to page 3

ady-to-install solutions Large or small pinion is no longer a question of mounting options During the choice of the pinion size, the size of the pitch circle on the gear unit flange shaft no longer needs to be taken into account. Now flanged pinion with the lowest possible number of teeth can be used. ZTRS-PH721 1 stage As a result the linear stiffness of the rack and pinion drive is increased by up to 100 %. The pinion size affects the linear stiffness C L constant Linear stiffness through small lever arm ZTR-PH with straight-cut flanged pinion The complete range for rack and pinion drives...

Open the catalog to page 4

With perfectly matched components The complete solution from a single source Due to the close co-operation with the world market leader and manufacturer of ATLANTA precision gear racks, STÖBER can offer comprehensive and uncompromisingly configured complete solutions. The synergy effect of quality, precision and interaction of all components results in optimum functionality. As a result these rack and pinion drives are also suitable for the highest requirements. ATLANTA series 29 Gearing: Right-hand 19° 31‘ 42” meshing angle 20° Modulus 2 / 3 / 4 / 5 / 6 / 8 / 10 / 12 Quality 5 and 6 Teeth...

Open the catalog to page 5

STÖBER offers consistent solutions Note on the design of axes and drives As a system supplier STÖBER has its own complete product range for digital drive technology. The MC6 motion controller uses the CODESYS programming software to keep up with the trend towards open systems in the world of automation. For optimum axis design, it makes sense to focus primarily on the gear units or geared motors. A useful aid is the design software SERVOsoft which you can download from the STÖBER website (PRODUCTS > Software/Download > SERVOsoft). The STÖBER service system comprises 38 expert partners in...

Open the catalog to page 6All STÖBER catalogs and technical brochures

-

Bottom brake resistor

14 Pages

-

PS Two-speed Gearbox

26 Pages

-

ServoFit Servo Gear Units

539 Pages

-

ServoFit® PE

20 Pages

-

Synchronous Servo Geared Motors

26 Pages

-

SMS PEPlanetary Geared Motors

14 Pages

-

STÖBER DIRECT 2011

12 Pages

-

ZV Rack and Pinion Drive

2 Pages

-

Target Industry Packaging

8 Pages

-

Target Industry Machine Tools

12 Pages

-

POSIDYN® SDS 5000 Servo Inverter

14 Pages

-

PE Planetary Gear Unit

6 Pages

-

Energy Efficiency

6 Pages

-

SD6 Drive Controller

12 Pages

-

MC6 Motion Controller

12 Pages

-

SMS Servo Geared Motors EZ

556 Pages

-

Variable speed drives

243 Pages

-

SMS/MGS Gear units

163 Pages

-

SMS Servo Geared Motors ED/EK

620 Pages

-

Rack and pinion drive ZTRS/ZTR/ZR

180 Pages

-

ServoCool Planetary gear units

88 Pages

-

MGS Modular Geared Motors System

325 Pages

-

MGS AC Geared Motors IE2

285 Pages