Catalog excerpts

Maximum flexibility for industrial automation with integrated CODESYS programming environment

Open the catalog to page 1

Complex motion sequences, high dynamics and precision Shorter cycle times and higher precision are permanent concerns where innovations in production technology and logistics are involved For drive engineering systems these constantly growing requirements mean that the motion sequences keep getting faster and must be very precisely coordinated. So the control system and drive mechatronics are central to the development towards more productivity and flexibility. This means that for more and more applications it is no longer enough to provide motion control by pooling of the drive control...

Open the catalog to page 2

Collaborative commitment is the short path to the goal It is a long way from an idea, then concept and design, to successful commissioning of a machine or automation device. Control and drive engineering issues are nearly always the focus when seeking the solution. As a system manufacturer STÖBER has the comprehensive know-how and detailed drive engineering experience to understand these projects fully and provide targeted advice and support. Creating concepts, agreeing feasibility, developing solutions, initial commissioning and global aftersales service are all included in the service...

Open the catalog to page 3

Synergy of functions, movements and power The joining of drive control and drive engineering systems generates high optimization potential Machinery and automation manufacturers have the best sales arguments if they can present a convincing complete control and drive engineering solution for challenging tasks. The market standard for control programming under IEC 61131-3 Due to the development of the new MC6 motion controller and its integration in the STÖBER product portfolio, suitable, very user friendly engineering solutions can be offered for drive engineering systems from a single...

Open the catalog to page 4

CODESYS – this widely used programming software allows open motion control system concepts CODESYS – from 3S-Smart Software Solutions – is a hardware independent programming software or complete programming system for the international standard PLC programming language IEC 61131-3. Due to its popularity, this Windows software tool represents a de facto market standard for hardware independent development systems. So it is generally possible to integrate many different peripheral modules in the control concept. The new MC6 motion controller from STÖBER is already equipped with the new...

Open the catalog to page 5

The new control system for highly dynamic precision axes MC6 motion controller, cabinet PC version This super compact, powerful motion controller is optimized for operation with the CODESYS V3 programming system. Programming of the application is carried out on a PC (CODESYS programming level). The technical features are impressive: With the efficient convection cooling, a fan is not required. A solid state drive (SSD) is used as the storage medium. With this hardware rotating parts could be completely eliminated. No data loss in the event of a 24 V power failure. The Windows interface can...

Open the catalog to page 6

The STÖBER complete motion control solution MC6 motion controller with touch screen panel for installation in an enclosure In the touch screen panel version the controller is ideal for use as master control but also as motion controller. For applications with a parameterization requirement, the panel version is particularly suitable as a visual sensitive interface and represents a contemporary form of user-friendly interaction. The other technical functions are the same as for the motion controller with DIN rail mounting. MC6 motion controller with touch screen function for installation in...

Open the catalog to page 7

The open industry standard for PLC and motion control Technical specifications - CODESYS programming system Logic Controllers) • Very high flexibility even in the standard version • Sequential function chart (SFC) • Continuous function chart (CFC) • Function block diagram (FBD) Extensive simulation options are possible at programming level on The CODESYS programming envi- ronment is available free of charge. Motion programming with PLCopen compliant modules • Integrated motion designer • Cams can be connected directly • Any coupling between different types of axis (virtual, real) • Cam...

Open the catalog to page 8

Complete solution with tailor-made services The benefit for CODESYS ... or build specific CODESYS skills users: Everything is familiar with STÖBER seminars STÖBER offers you support and services specially designed for your requirement. Anyone familiar with CODESYS can go ahead and program an application for the MC6 motion controller. You can also use the STÖBER technology support for troubleshooting or optimization of an existing system. When programming standard applications, users are supported effectively by the consistent object orientation of the modules. With the design and...

Open the catalog to page 9

MC6 motion controller – Technical data Model Type codes With panel 1.6 GHz Intel® Atom™ (Z530 series) FSB 533 MHz, L2 cache 512 KB Internal cFAST socket for SATA based SSD module 1 x 10/100/1000 Mbit/s Ethernet 1 x 10/100 Mbit/s Ethernet Visu software option N 3 x USB 2.0 interface (480 Mbit/s), with 500 mA current rating 2 x freely programmable LEDs 128 KB nvSRAM (no battery backup necessary) Battery-powered realtime clock Internal watchdog Internal temperature control Video controller (Intel GMA 500) with up to 256 MB video memory use DVI-D monitor connection Internal LVDS monitor...

Open the catalog to page 10

Unit and installation dimensions MC6 motion controller with touch screen panel For installation in operator station Enclosure IP 65 Weight approx. 4.8 kg MC6 motion controller In the cabinet PC version Weight approx. 0.8 kg STÖBER system technology for uncompromising motion control solutions With this wide and varied range of drive axes, very specific motion drive applications can be achieved

Open the catalog to page 11

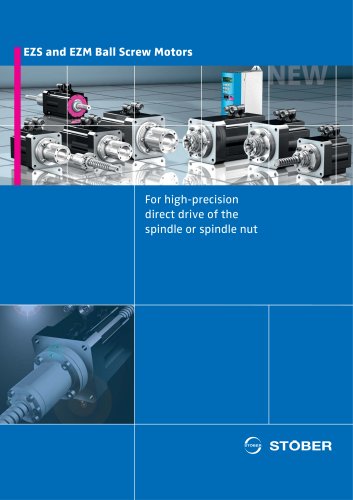

Note on the design of axes and drives As a system supplier STÖBER has its own complete product range for digital drive technology. The MC6 motion controller uses the CODESYS programming software to keep up with the trend towards open systems in the world of automation. For optimum axis design, it makes sense to focus primarily on the gear units or geared motors. A useful aid is the design software SERVOsoft which you can download from the STÖBER website (PRODUCTS > Software/Download > SERVOsoft). The STÖBER service system comprises 38 expert partners in Germany and more than 80 companies in...

Open the catalog to page 12All STÖBER catalogs and technical brochures

-

Bottom brake resistor

14 Pages

-

PS Two-speed Gearbox

26 Pages

-

ServoFit Servo Gear Units

539 Pages

-

ServoFit® PE

20 Pages

-

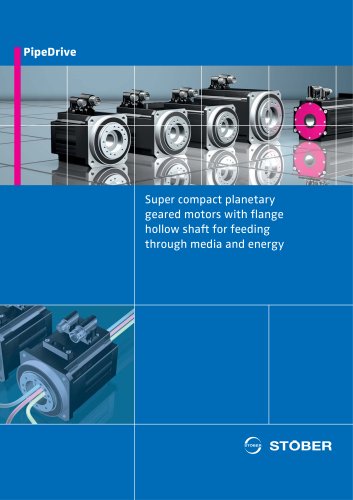

Synchronous Servo Geared Motors

26 Pages

-

SMS PEPlanetary Geared Motors

14 Pages

-

STÖBER DIRECT 2011

12 Pages

-

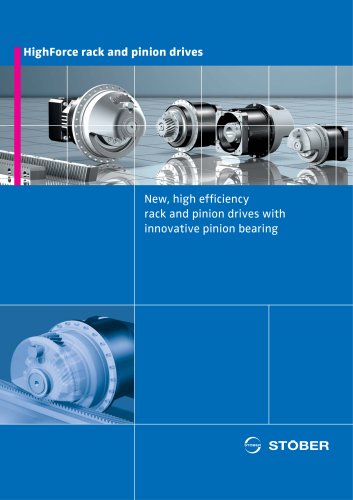

ZV Rack and Pinion Drive

2 Pages

-

ZTRS Rack and Pinion Drive

6 Pages

-

Target Industry Packaging

8 Pages

-

Target Industry Machine Tools

12 Pages

-

POSIDYN® SDS 5000 Servo Inverter

14 Pages

-

PE Planetary Gear Unit

6 Pages

-

Energy Efficiency

6 Pages

-

SD6 Drive Controller

12 Pages

-

SMS Servo Geared Motors EZ

556 Pages

-

Variable speed drives

243 Pages

-

SMS/MGS Gear units

163 Pages

-

SMS Servo Geared Motors ED/EK

620 Pages

-

Rack and pinion drive ZTRS/ZTR/ZR

180 Pages

-

ServoCool Planetary gear units

88 Pages

-

MGS Modular Geared Motors System

325 Pages

-

MGS AC Geared Motors IE2

285 Pages