Catalog excerpts

Type BPM APPLICATIONS: • UST D • PARTICLES Downdraft T ables Type BPM Self contained – Multi-use – Robust – Safe – Reliable – Efficient - Quiet The Stivent Grinding and Polishing Station keeps all emitted particles well away from the operator due to its unique design and a built-in exhaust fan. Particles are captured right where they are produced using vertical air flow through the work surface. Key Points Reduced operator exposure for any dust producing operations which involve processing material on a bench grinder. Quiet: less than 70 dB measured at the work surface Standard Features: • Control Panel • Metal work surface with dual extraction area • Vertical air-sheet fan • Flexible side panels • Castor wheels • Painted light grey (RAL7035) Fault monitoring system Low maintenance cost: electronic control 99% high filtration pleated filter cartridges Environmental protection Grinding, polishing, deburring, resurfacing, adjustment. Personnel protection Overall Dimensions in mm (DxWxH) Options: choice of paint, suction at source, high pressure, additional compressed air outlet, retractable side roller blinds (transparent or coloured), knitted wire mesh pre-filter for incandescent particles, specific cartridges (PTFE, anti-static etc.), modular lighting with 35W flexible light, 99.95% H13 HEPA filter for interior exhaust discharge, modification for external discharge, ATEX (LCIE) certification for use inside and outside hazardous areas (remote control panel), soundproofed working area enclosure, particle sensor, single phase 230 V power supply. Mechanical Engineering Aluminium Ship building Sanitary ware Air Handling – Aspiration - Filtration CHU PELLEGRIN PODOLOGIE, CENTRE MAINTENANCE AIR FRANCE, etc. Customers Include:

Open the catalog to page 1All STIVENT Industrie catalogs and technical brochures

-

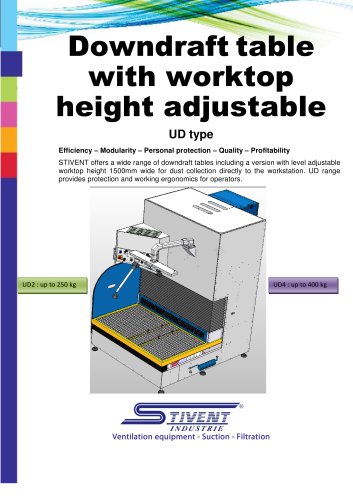

Downdraft Tables

1 Pages

-

U&D

10 Pages

-

BACKPANEL EXTRACTORS

1 Pages

-

TMFI

1 Pages

-

downdraft table TC 700

1 Pages

Archived catalogs

-

downdraft table Up & Down

10 Pages