Catalog excerpts

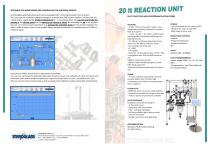

Any Steroglass pilot/laboratory plant can be equipped with a PLC programmable control system. The user now has a suitable software package in an interactive HMI (Human machine interface) for con‐ trolling and/or regulating the product temperature by re‐circulating chiller, the vacuum level inside the glassware, the stirring speed and the opening and closing of valves. By measuring the pH in the product the user can create cascade operations (e.g. activate the peristaltic pump for the product loading). The HMI is made through a touch screen graphic display designed specifically for industrial plants, SCADA is a standard option. According to cGMP, several levels of passwords are available. The user can control all the pilot plant operation driven by sensor, the software will store the log of each parameter (the trend of product temperature, vapor flux temperature, vacuum, actuated events, etc. ) The user can set alarms and warnings as well as saving and recalling the system setups (the working data). STEROGLASS S.r.l. Strada Romano di Sopra 2/C, 06132 San Martino in Campo (PG), Italia Tel. +3907560909-1 fax. +390756090950 e-mail. info@steroglass.it FEATURES ‐ 20 liter 3.3 borosilicate glass reactor, inter‐ changeable, graduated, jacketed for thermal fluid recirculation ‐ ‐1.0 to + 0.5 bar / ‐ 45 (‐90) to + 200°C (extra low temperature achievable with triple wall jacketed vessels) ‐ 10...280 rpm continuous adjustable stirrer with a 0.22 kW 400Vac induction motor ‐ Dry running mechanical seal ‐ CE / GMP ‐ CIP capable ‐ Materials: 3.3 borosilicate Glass / PTFE / TFM in compliance with FDA and GMP directives and highly corrosive environment ‐ Bottom valve: borosilicate glass 3.3 and PTFE dead space free ‐Optional chiller/thermostat with PLC supervi‐ sion FRAME ‐ 1" frame, stainless steel tubing, overall di‐ mension 1680 X 2452 X 729mm high ‐ Laboratory fume hood for contained opera‐ tions as optional COVER PLATE ‐ DN80 fast‐action closure for solids addition ‐ Standard version with flat flange connections ‐ Various options of connections available GLASS OVERHEAD Distillation overhead consisting of: ‐ 10 liter feed vessel ‐ Vapor duct with reflux splitter ‐ 0.3m2 coil heat exchanger ‐ 2x5 liter graduated glass receiver vessel ‐ Vacuum connection ‐ Nitrogen connection (0.4 Barg max) DOCUMENTATION Manuals, P & ID, layout drawing, IQ / OQ / PQ list STIRRER ‐ Interchangeable stirrers made of PTFE ‐ Blade stirrer made of solid PTFE ‐Wide range of stirrer style SENSOR AND CONTROLS ‐Vacuum ‐Product temperature, ‐Vapor temperature, ‐pH SAFETY ‐Rupture disk: 0.49Barg UTILITY REQUIREMENTS ‐Power supply: 400V, 3 F + N + PE, 16A 50Hz ‐Compressed air: max 2 Bar (Optional for actuated valves)

Open the catalog to page 1

COMPANY OVERVIEW For over 50 years Steroglass has established itself on the Italian and foreign market reaching the highest professional standards in the production and technical assistance in the field of industrial plants. Steroglass is a worldwide leader in design and construction of pilot plants for the industrial chemical processes. Steroglass offers a wide range of pilot plants ideal for didactics, research and production. Through appropriate optional items, it is possible to obtain plants for various applications. ...

Open the catalog to page 2All Steroglass catalogs and technical brochures

-

Waterlab

3 Pages

-

STRIKE 300

9 Pages

-

ROTARY EVAPORATORS

8 Pages

-

PHARMA REACTOR

8 Pages

-

FLASH AUTOMATIC TITRATOR

3 Pages

-

EASYCHEM GLASS REACTORS

8 Pages

-

EASY CHECK

1 Pages

-

ONE Wine analyzer

2 Pages

-

General catalogue 2020

156 Pages

-

Rotary Evaporator Strike 100

4 Pages

-

Glass Reaction System

49 Pages

-

Spare parts general catalogue

66 Pages

-

SS & HC Reactors

1 Pages

-

SS & HC Filters

2 Pages

-

SS & HC Pressfilters

1 Pages

-

Ionix Oenology

6 Pages

-

UP-LAB Spectrophotometer

2 Pages

-

hyperlab

6 Pages

-

criocheck

2 Pages

-

Lab Reactor

2 Pages

-

Rotary Evaporator Strike 300

9 Pages

-

Heavy Metal Analyzer Ionix

9 Pages