Catalog excerpts

GLASS REACTION SYSTEM – PROCESS DIVISION Steroglass St l GLASS REACTION O SYSTEM

Open the catalog to page 1

2013 PRODUCT OVERVIEW – PROCESS DIVISION MAIN TARGETS: Chemical reactions and Ch i l ti d study/production of molecules, polymers, etc.

Open the catalog to page 2

2013 PRODUCT OVERVIEW – PROCESS DIVISION MAIN TARGETS Steroglass Glass Reaction Systems are y suitable for chemical process d development, l t scale up and process simulation

Open the catalog to page 3

2013 PRODUCT OVERVIEW – PROCESS DIVISION SYNTESIS PROMO STRIKE 300 LABORATORIES Organic Chemistry Pharmaceutical Chemistry Industrial Chemistry Food

Open the catalog to page 4

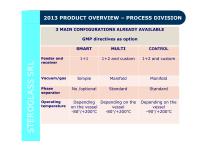

2013 PRODUCT OVERVIEW – PROCESS DIVISION -SMART -MULTI MULTI -CONTROL

Open the catalog to page 5

2013 PRODUCT OVERVIEW – PROCESS DIVISION

Open the catalog to page 6

2013 PRODUCT OVERVIEW – PROCESS DIVISION SMART PROMO STRIKE 300 This is the configuration for a fi ti f smart basic reaction package. Manual valves and operations, local analogic instruments, mainly intended to b used with a thermocirculator with be d i h h i l i h a special fluid in the vessel jacket.

Open the catalog to page 7

2013 PRODUCT OVERVIEW – PROCESS DIVISION

Open the catalog to page 8

2013 PRODUCT OVERVIEW – PROCESS DIVISION The classical multipurpose configuration. The number and the type of the co po e ts a o components allow a wide range of de a ge o operations. The package comes with a PLC to record and visualize the critical parameters of the process process.

Open the catalog to page 9

2013 PRODUCT OVERVIEW – PROCESS DIVISION

Open the catalog to page 10

2013 PRODUCT OVERVIEW – PROCESS DIVISION CONTROL PROMO STRIKE 300 This is the ultimate version in terms of performance. Triple Walled Glass Reactor or Glass Lined Reactor for the most demanding operations, from –90°C up to 200°C. The package comes with a PLC to record and visualize the critical d d i li th iti l parameters of the process.

Open the catalog to page 11

2013 PRODUCT OVERVIEW – PROCESS DIVISION 3 MAIN CONFIGURATIONS ALREADY AVAILABLE SMART Glassware Multiple choice Glass lined Special Steel Temperature p Product and reading vapour analogic Product, vapour Product, vapour and and receiver with receiver with remote remote temperature temperature probes probes Visualization and Vi li ti d Visualization and management of the management of the parameters with a parameter with a PLC PLC based software based software

Open the catalog to page 12

2013 PRODUCT OVERVIEW – PROCESS DIVISION 3 MAIN CONFIGURATIONS ALREADY AVAILABLE PROMO STRIKE 300GMP directives as option Phase separator Depending Depending on the on the vessel vessel -80°/+200°C -80°/+200°C

Open the catalog to page 13

2013 PRODUCT OVERVIEW – PROCESS DIVISION STANDARD PACKAGES:

Open the catalog to page 14

2013 PRODUCT OVERVIEW – PROCESS DIVISION SOME PACKAGE EXAMPLES -5 & 10 lt DOUBLE JACKETED GLASS MULTI PURPOSE REACTION UNITS UNDER VACUUM -20 lt DOUBLE JACKETED GLASS MULTI PURPOSE REACTION UNIT UNDER VACUUM -25 lt & 50lt EX-PROOF DOUBLE JACKETED GLASS MULTI PURPOSE REACTION UNITS UNDER VACUUM - 25 lt & 50lt EX-PROOF DOUBLE JACKETED HASTELLOY MULTI PURPOSE REACTION UNITS UNDER VACUUM -50lt GLASS ROUND VESSEL WITH OIL BATH MULTIPURPOSE REACTION UNIT -100 & 200 lt ARE AVAILABLE UPON REQUEST

Open the catalog to page 15

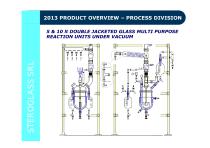

2013 PRODUCT OVERVIEW – PROCESS DIVISION 5 & 10 lt DOUBLE JACKETED GLASS MULTI PURPOSE REACTION UNITS UNDER VACUUM

Open the catalog to page 16

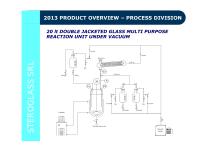

2013 PRODUCT OVERVIEW – PROCESS DIVISION 20 lt DOUBLE JACKETED GLASS MULTI PURPOSE REACTION UNIT UNDER VACUUM Vacuum pump

Open the catalog to page 17

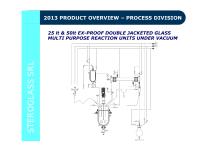

2013 PRODUCT OVERVIEW – PROCESS DIVISION 25 lt & 50lt EX-PROOF DOUBLE JACKETED GLASS MULTI PURPOSE REACTION UNITS UNDER VACUUM

Open the catalog to page 18

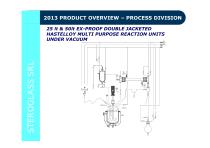

2013 PRODUCT OVERVIEW – PROCESS DIVISION 25 lt & 50lt EX-PROOF DOUBLE JACKETED HASTELLOY MULTI PURPOSE REACTION UNITS UNDER VACUUM

Open the catalog to page 19

2013 PRODUCT OVERVIEW – PROCESS DIVISION 50lt GLASS ROUND VESSEL WITH OIL BATH MULTI-PURPOSE REACTION UNIT Vacuum Rupture disk Nitrogen Vacuum Feed load Solid load

Open the catalog to page 20

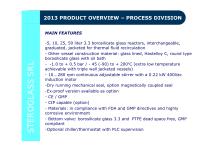

2013 PRODUCT OVERVIEW – PROCESS DIVISION MAIN FEATURES -5, 10, 25, 50 liter 3.3 borosilicate glass reactors, interchangeable, graduated, jacketed for thermal fluid recirculation - Other vessel construction material: glass lined, Hastelloy C, round type borosilicate glass with oil b th b ili t l ith il bath - -1.0 to + 0.5 bar / - 45 (-90) to + 200°C (extra low temperature achievable with triple wall jacketed vessels) - 10 280 rpm continuous adjustable stirrer with a 0.22 kW 400Vac 10...280 0 22 induction motor -Dry running mechanical seal, option magnetically coupled seal -Ex-proof version...

Open the catalog to page 21

2013 PRODUCT OVERVIEW – PROCESS DIVISION Frame - Stainless steel tubing, to suit available space - Laboratory fume hood for contained operations as optional Cover plate -Material of construction: borosilicate glass, PTFE coated steel, glass li d steel l lined t l - DN80 fast-action closure for solids addition - Standard version with flat flange connections - Various options of connections available Glass overhead Distillation overhead consisting of: - f d vessel feed l - Vapor duct with reflux splitter, automatic or simple - coil heat exchanger - graduated glass receiver vessel - Vacuum...

Open the catalog to page 22

2013 PRODUCT OVERVIEW – PROCESS DIVISION Stirrer - Interchangeable stirrers made of PTFE - Blade stirrer made of solid PTFE -Wide range of stirrer style: anchor, impeller, turbine, rushton type Sensor and controls -Vacuum -Product temperature, temperature -Vapor temperature, -pH Safety -Rupture disk: 0.49Barg For a correct configuration please ask for Pilot Plant Questionnaire

Open the catalog to page 23

2013 PRODUCT OVERVIEW – PROCESS DIVISION Reactor Components: -Glass reactor single wall with direct heating with oil bath/electric heating. h ti ith il b th/ l t i h ti -Glass reactor double wall with jacket recirculation -Glass reactor triple walled with jacket recirculation -Full Glass lined/bottom glass lined -Glass Cover or low profile Glass Lined Glass Cover

Open the catalog to page 24

2013 PRODUCT OVERVIEW – PROCESS DIVISION Stirring & Coupling: Basic d B i dry seal with PTFE stirring shaft l ith ti i h ft Different design available (anchor,impeller,turbine ) (anchor impeller turbine ...) Magnetic coupling as option ATEX version always available as option Baffles ,made of glass of PTFE Optional Glass Lined

Open the catalog to page 25All Steroglass catalogs and technical brochures

-

Waterlab

3 Pages

-

STRIKE 300

9 Pages

-

ROTARY EVAPORATORS

8 Pages

-

PHARMA REACTOR

8 Pages

-

FLASH AUTOMATIC TITRATOR

3 Pages

-

EASYCHEM GLASS REACTORS

8 Pages

-

EASY CHECK

1 Pages

-

ONE Wine analyzer

2 Pages

-

General catalogue 2020

156 Pages

-

Rotary Evaporator Strike 100

4 Pages

-

Pilot Plant 20 lt

2 Pages

-

Spare parts general catalogue

66 Pages

-

SS & HC Reactors

1 Pages

-

SS & HC Filters

2 Pages

-

SS & HC Pressfilters

1 Pages

-

Ionix Oenology

6 Pages

-

UP-LAB Spectrophotometer

2 Pages

-

hyperlab

6 Pages

-

criocheck

2 Pages

-

Lab Reactor

2 Pages

-

Rotary Evaporator Strike 300

9 Pages

-

Heavy Metal Analyzer Ionix

9 Pages