Catalog excerpts

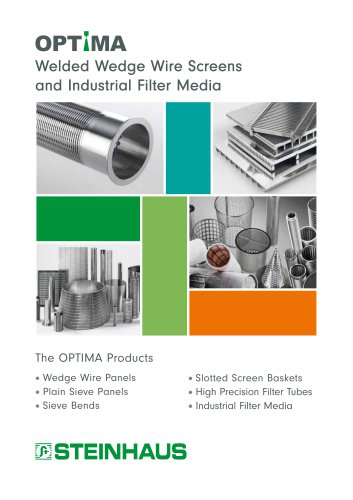

The OPTIMA Products • Wedge Wire Panels • Plain Sieve Panels • Sieve Bends • Slotted Screen Baskets • High Precision Filter Tubes • Industrial Filter Media

Open the catalog to page 1

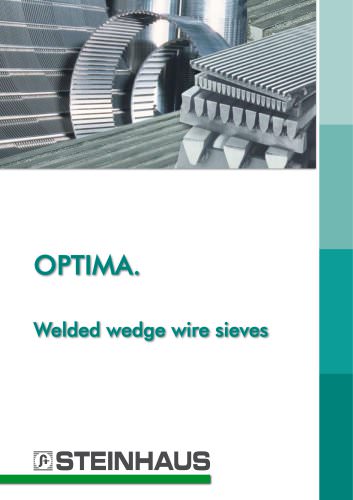

star-shape distributor With welded wedge wire screens cold drawn triangle shaped profiles are used as slot performing wires. Excellent mechanical properties for rigid applications with, at the same time, high precision slots are the special quality features. OPTIMA wedge wire screens are often used for solid/ liquid separation in practically unlimited applications, such as dewatering pipes, filter candles, sieve baskets, filter drums or centrifuge screens. Wedge wire screens and filter for your applicatation On screening machines, as sieve bends, in centrifuges for dewatering, for...

Open the catalog to page 2

The successful separation of materials in various processes, mainly in the solid/liquid separation is of high priority in many sectors of industries. OPTIMA welded wedge wire centrifuge baskets offer an optimum separation result because of their superior workmanship and high fitting accuracy. Centrifuges as well as separators are in operation in the following sectors: • Chemical industry • Food industry • Waste water treatment • Sand & gravel industry • Enviromental applications (bio gas) • Mining industry OPTIMA welded wedge wire baskets are often found in: • Centrifuges with conical or...

Open the catalog to page 3

OPTIMA spiral cylinders are produced in diameters up to 1022 mm and lengths of 5500 mm. OPTIMA precision filter tubes made by highly accurate automatic welding machines, on the other hand, cover a diameter range from 23 mm to 305 mm. All OPTIMA products are characterized by a sturdy construction for mechanically demanding applications. The high pressure resistance of our filter tubes can be reinforced further with supports, such as inside square wire spirals. With specially developed profile wires slots width down to 6 micron can be realised. • FOTI (filtration from outside to inside)...

Open the catalog to page 4

In this axial design the slot performing wires follow the axis of the wedge wire cylinder. The crossbars are spirally winded and welded on the profile wires from the outside. The working surface on the inside is smooth and not interrupted. This cylinder type is either produced directly or by counter rolling from a plain screen panel. The special feature is the smooth inner working / filtration side, which allows the use of scrapers for cleaning. This very latest OPTIMA innovation with square filter holes follows a new application concept. The patented execution can be used with filtration...

Open the catalog to page 5

Plain or bended wedge wire panels find their use in the following sectors of industry: • OPTIMA plain sieve panels with or without reinforcement in dewatering and screening machines • OPTIMA filter bottoms for diffusion and extraction towers, plain filters, ion exchange systems, back flush filters etc. ... • OPTIMA support panels for filter fleece in belt filters • OPTIMA sieve bends with slots across flow direction for an optimal solid / liquid separation • OPTIMA architectural grids for cladding of building facades • OPTIMA kiln and lautering floors in breweries and malthouses The range...

Open the catalog to page 6

OPTIMA Wedge Wire Panels Types of Reinforcement Plain OPTIMA slotted screens could be reinforced according to their needs to secure the proper installation. • Steel reinforcement: Reinforcements made of various steel grades and designs according to client’s specification. Whether with a frame for clamp fixing or with drilled side rails for screwing, all is possible. Often plain sieve panels in smaller dimensions are supplied as one piece ready for installation. Bigger panels, however, are made of several segments to allow an easier handling and building-in. These individual segments could...

Open the catalog to page 7

The profile wires are connected to the crossbars by means of high pressure resistance welding. So this construction of the whole segment is slot secure and high resistant. Individual parameters for the production are computer-controlled at the welding machine. Permanent verification of individual parameters, such as the level of welding current, leads to safe-guarding a constant quality combined with high mechanical stability. The triangular shape of the slot performing wires practically excludes the clogging of individual slots. The downward widening slot in flow direction prevents...

Open the catalog to page 8

OPTIMA Industrial Filter Media Economical and reliable Formfilters for separating solid and suspended matter out of liquids and gases in valve fittings, pipework, pumps, hydraulic and air-conditioning systems. In mechanical engineering, in the chemical and pharmaceutical industry, in the iron and steel industry, in power station systems, in the petrochemical industry, in coolant treatment, in water treatment and in the foodstuffs industry. Formfilters, being classic surface filters, prevent machine damage and can generally be cleaned and re-used. We manufacture shaped filters in all...

Open the catalog to page 10

OPTIMA Industrial Filter Media Start-up filters have the job during the initial start-up of equipment in pipeline and apparatus construction of removing production residues like slags and electrode residues that have found their way into the system by fitting and welding work. Damage to system parts fitted downstream is thus prevented and the risk of costly operational disruptions markedly reduced. Start-up filters comprise a support element made from perforated metal sheet or wire mesh, onto which the actual fine mesh filter cloth is fitted, plus a flanged ring for fastening in the...

Open the catalog to page 11

Electroformed micro-perforated plates Micro-perforated plates have done much to help solving difficult separation problems in e.g. centrifuges, particularly in the chemical and foodstuff industries. They now supplement fine-screen plates made from punch-perforated sheets or wire cloths for separating processes that call for the highest precision and optimum through-put. Micro-perforated plates manufactured galvanotechnically from pure nickel have found use in numerous branches of industry in recent years. STEINHAUS supplies micro-perforated plates in the form of sheets and segments of all...

Open the catalog to page 12All Steinhaus catalogs and technical brochures

-

Cleanbelt

2 Pages

-

Wire Mesh Conveyor Belts

8 Pages

-

Polyurethane Screens

8 Pages

-

Enrobing Belts.

2 Pages

-

Airspring

8 Pages

-

filter media

12 Pages

-

Sieves

8 Pages

-

Groups 100/200

5 Pages

-

Enrobing Belts

2 Pages

-

High Precision Filter Tubes

8 Pages

-

KOMBIPLAST® UNI 2000.

16 Pages

-

Sieves - Delivery Program

8 Pages

-

A reliable Partner

6 Pages

Archived catalogs

-

OPTIMA_2007

8 Pages