Catalog excerpts

Challenge > A fleet of 40 pieces of construction equipment must be available 24/7 to finish a job. Theres no spare time in the project, so maintenance has to mesh with operations. Data from sensors on the equipment exceeds the ability of maintenance personnel to interpret it. Caterpillar uses PROCEED models to drive preventative actions, reducing costs and increasing uptime. The PROCEED Solution > PROCEED finds knowledge in the chaos of information, models it and gives the owners a way to prevent crippling failures while minimizing cost Data PROCEED Actions Results > Gigabytes of data recorded from over 100 sensor channels is collected from a fleet of construction equipment of varying ages.Experts working with the PROCEED software create a model which maps input sensor signals to output sensor results. The models then switch from historical to real-time data.PROCEED alerts the customer to the action priority for each piece of equipment.Caterpillar uses the PROCEED software to prevent 80 machine-days of downtime and results in a 40% reduction in consumables. Results Caterpillar uses the PROCEED software to prevent 80 machine-days of downtime and results in a 40% reductionin consumables. size="-5">

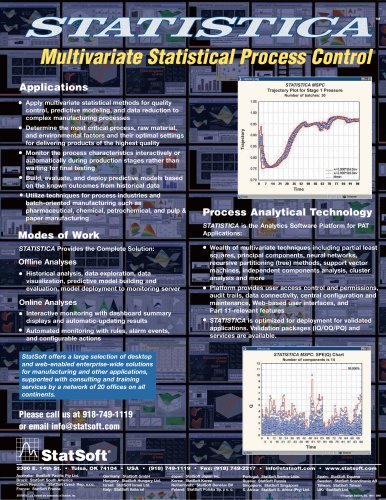

Open the catalog to page 1All STATSOFT catalogs and technical brochures

-

STATISTICA_Enterprise

2 Pages

-

STATISTICA DATA MINER

2 Pages

-

Six Sigma

2 Pages

-

Desktop Solutions STATISTICA

1 Pages

-

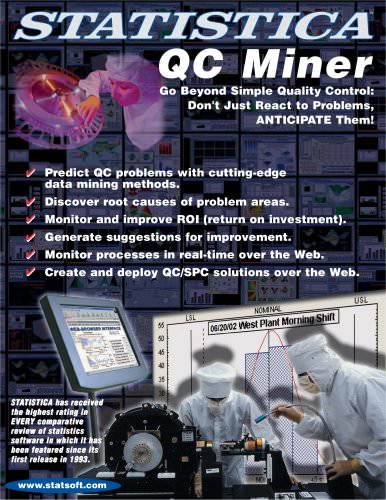

STATISTICA QC Miner

2 Pages

-

STATISTICA Neural Networks

2 Pages

-

STATISTICA Data Miner

2 Pages

-

STATISTICA Data Warehouse

5 Pages

-

WebSTATISTICA

2 Pages