Catalog excerpts

Challenge > In industrial machine equipment, rotating assemblies are frequently the source of vibration. Perfecting the balance minimizes vibration, and maximizes power and durability. Conventional wisdom says that balance must be achieved through expensive testing, tighter tolerances and additional manufacturing steps. Caterpillar improvesmachine balance through process control and reduces product testing by 45%. The PROCEED Solution > Caterpillar uses the PROCEED software to find the key to achieving balance from fundamental process changes and simultaneously reduces costly and time consuming testing. Data PROCEED Actions Results > Traditional SPC data from manufacturing processes and production test results are used to build a PROCEED software model of the cause and effect possibilities.Engineers use PROCEED software to find a small subset of critical dimensions, from a large population of candidate variables, which accurately models the relevant interrelationships and subsequently returns an optimal solution. What-ifӔ analysis of the model, combined with the knowledge of the engineering experts, predicts that by implementing only 2 process changes a 50% decrease of vibration testing is expected at no additional cost. The changes are implemented and balance conditions are met. Actual product testing is reduced by 45% and quality is improved with no additional cost by simply acting on what was learned from the data using the PROCEED software. Results > Caterpillar uses the PROCEED software to reduce expensive and time consuming balance operations by managingthe variation in the critical that collectively are good predictors of vibration. A 45% improvement in production testing is achieved making only 2 process changes and at no additional cost by reacting to what the data is telling us to do. size="-3">

Open the catalog to page 1All STATSOFT catalogs and technical brochures

-

STATISTICA_Enterprise

2 Pages

-

STATISTICA DATA MINER

2 Pages

-

Six Sigma

2 Pages

-

Desktop Solutions STATISTICA

1 Pages

-

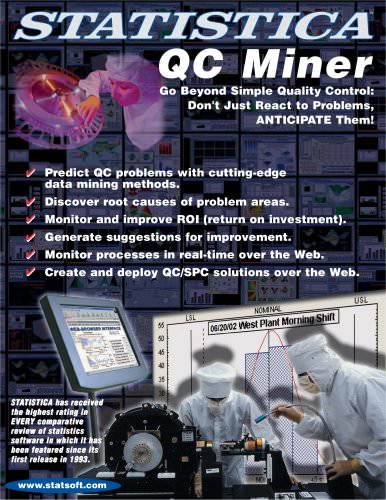

STATISTICA QC Miner

2 Pages

-

STATISTICA Neural Networks

2 Pages

-

STATISTICA Data Miner

2 Pages

-

STATISTICA Data Warehouse

5 Pages

-

WebSTATISTICA

2 Pages