Catalog excerpts

TECHNICAL DATA SHEET SOLDER PASTE SP6000 lead free No-Clean solder paste PRODUCT DESCRIPTION The solder paste SP6000 is part of Stannol's sustainable greenconnect product line. The special feature: With SP6000, more than 85 percent of CO2 emissions can be saved compared to conventional solder pastes mainly through the use of recycled solder. SP6000 has been developed for use with TSC305 (Sn96.5Ag3Cu0.5) T4 and TSC105 (Sn98.5Ag1Cu0.5) T4 alloys. The wetting properties have been optimised for all known lead-free surfaces on PCBs and components. The very few residues are transparent and noncorrosive after the reflow process. CLASSIFICATION AND PROPERTIES The product offers following advantages: • • • • • • • • solder powder made from recycled solder 85 percent CO2 savings very suitable for use with low silver content (TSC105) suitable for fine pitch up to 0,4 mm very good first print results after longer printer downtime reflow process under air or nitrogen possible very good wetting on most surfaces RoHS compliant APPLICATION Solder paste printing: The SP6000 solder paste has been developed for stencil printing. With the TSC105 or TSC305 alloy and particles type 3 (25-45 µm) and 4 (20-38 μm), the SP6000 solder paste can be used in all common open and closed printing systems. Stencil thickness: 100-150 µm (depending on application) Recommendations for solder paste printing: 1. Generally, use the thinnest stencil possible. 2. Use stencils with rounded corners to minimise clogging of the stencil openings. 3. Set the squeegee pressure to 0.25 kg/cm squeegee length. Then reduce the squeegee pressure in small steps until the solder paste starts to smear. Now the squeegee force is set to the optimum. Make these adjustments at your desired print speed. 4. The optimum printing speed with the SP6000 solder paste is in the range of 20-100 mm sec-1. 5. Pay close attention to the sealing of the PCB and stencil. The PCB must be very well supported in order to seal against the stencil and the solder paste cannot be pushed sideways past the pads. Reflow profiles: The reflow process can be performed under air and nitrogen. The temperature profile below is typical and has shown good wetting results when used with SP6000 solder paste. However, other profiles can be applied depending on the available equipment and solder as well as requirements of PCB. For this solder paste, a linear reflow profile is recommended. If a saddle profile is chosen, the temperature load in the preheater should not exceed a time of 120 seconds at temperatures around 180 °C. STANNOL GmbH & Co. KG o Stand: 08.11.2023 Haberstr. 24 • D-42551 Velbert • Tel: +49 (0)2051-3120-0 • Fax: +49 (0)2051-3120-111 • E-Mail: info@stann

Open the catalog to page 1

The data in the table are typical values and do not represent a specification. STANNOL GmbH & Co. KG o Stand: 08.11.2023 Haberstr. 24 • D-42551 Velbert • Tel: +49 (0)2051-3120-0 • Fax: +49 (0)2051-3120-111 • E-Mail: info@stannol.de • www.stannol.de

Open the catalog to page 2

PACKAGING Stannol SP6000 solder paste can be supplied in: • 500 g plastic jars • 600 g Semco 6 oz oder 1200 g Semco 12 oz cartridges Other types of packaging are also available on request. These may be associated with certain minimum purchase quantities. At a storage temperature of 2 to 8 °C, the minimum shelf life (from date of manufacture) is 6 months in the unopened original container. Solder paste in cartridges (Semco 6 oz and 12 oz) should be stored upright with the cap of the dispensing opening facing downwards. If this is not possible, we recommend turning the lying cartridges by...

Open the catalog to page 3All Stannol catalogs and technical brochures

-

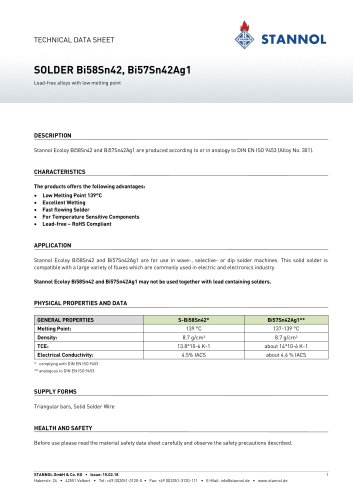

SOLDER Bi58Sn42, Bi57Sn42Ag1

2 Pages

-

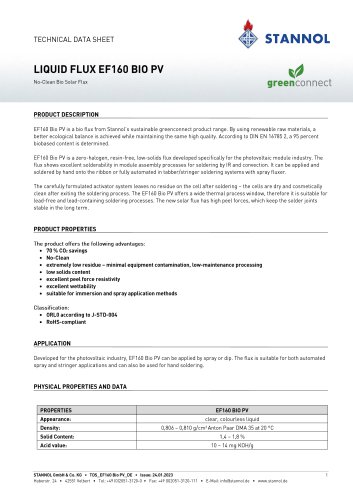

LIQUID FLUX EF160 BIO PV

2 Pages

-

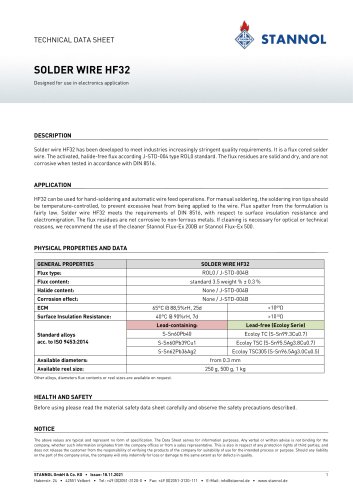

HF32

1 Pages

-

Greenconnect Catalogue 2024

12 Pages

-

Main Catalogue 2024

17 Pages