Catalog excerpts

STANNOL FLUX EF350 BIO greenconnect MADE IN GERMANY BOLDER PASTE green onnect greenconnectOur sustainable product line

Open the catalog to page 1

greenconnect – the sustainable product line from Stannol Stannol offers a complete product range called greenconnect, which focuses on the aspect of sustainability and fairness. In the past, only the criteria of quality, price and delivery time were of importance, especially when purchasing tin. However, due to the strong demand for raw materials, working and living conditions in the mining areas are largely inhumane. The environment also suffers greatly from the uncontrolled and partly illegal mining of raw materials. With our greenconnect products, we enable our customers to take a step...

Open the catalog to page 2

As proof of your commitment, you will receive a personalised, batch-related certificate on demand. ELEKTRONIK MIT VERANTWORTUNG BY STANNOL ZERTIFIKAT ELEKTRONIK MIT VERANTWORTUNG MUSTERFIRMA unterstützt den fairen Zinnabbau schont in besonderer Weise die Umwelt Verantwortung für Menschen und Beschäftigte vor Ort unterstützt transparentes und faires Handeln Stempel, Unterschrift Fairtin solder – environmentally friendly, sustainable and fairly produced The solder wires, solder pastes and solder bars from our greenconnect range all carry our Fairtin label. This means that primary tin from a...

Open the catalog to page 3

Our greenconnect products – solder wires SOLDER WIRE – KRISTALL 600 Although mildly activated, Kristall 600 solder wire ensures fast and good wetting on most surfaces. The flux contained is halide free and based on a synthetic resin matrix. Due to the high thermal stability, the flux is suitable for use with all lead-free alloys. PRODUCT ADVANTAGES • Fairtin solder • No-Clean • transparent, clear residues • greatly reduced spitting • high thermal resistance • good wetting • reduced health risks, as colophony-free • REL0 classification APPLICATION AREAS Kristall 600 solder wire can be used...

Open the catalog to page 4

SOLDER WIRES - KRISTALL 605 AND 611 Kristall 605 and Kristall 611 are halogen-activated solder wires that open the process window in various places. Strongly reduced flux spitting in combination with good wetting behaviour on poorly solderable surfaces are the highlights of these innovative products. PRODUCT ADVANTAGES • Fairtin solder • bright No-Clean residues • low spitting • very good wetting properties for fast soldering • chemically modified resin that reduces health risks • mild odour APPLICATION AREAS Developed for manual rework as well as for automated soldering equipment, Kristall...

Open the catalog to page 5

Our greenconnect products – solder pastes SOLDER PASTE – SP2200 Solder paste SP2200 was developed for high-volume, lead-free SMD electronics production. It contains a highly active L0 No-Clean flux. With a special formula for excellent wetting, it meets the requirements for surfaces found in any serial production today. The small amount of residue left after the reflow process is bright, transparent, electrically safe and does not need to be removed. PRODUCT ADVANTAGES • solder powder made from Fairtin solder • very good first print results after longer printer downtime • reflow process...

Open the catalog to page 6

SOLDER PASTE – SP6000 SP6000 solder paste was developed for use with alloy TSC305 (Sn96.5Ag3Cu0.5) as well as for cost-saving use with low silver content with alloy TSC105 (Sn98.5Ag1Cu0.5). The special feature: With SP6000, more than 85 percent of CO2 emissions can be saved by using recycled solder compared to conventional solder pastes. The flux, which is classified as REL0, also convinces with an uncompromising wetting quality on all known lead-free PCBs in both air and nitrogen atmospheres. SP6000 leaves behind exceptionally little residues, which are also transparent and non-corrosive....

Open the catalog to page 7

SOLDER FLUX MADE II FLUX - EF350 BIO The halogen-free activated No-Clean flux EF350 Bio guarantees an excellent wetting ability on different surfaces, for example OSP, Ni/Au, HAL, chem. Sn and chem. Ag, with both lead-free and lead-containing solder alloys. Important for our customers: Extensive tests have proven that a 1:1 exchange of the flux is possible without changing the process parameters. PRODUCT ADVANTAGES • significant CO2 savings • No-Clean • universally applicable • solids content 3.5 percent • very good wetting properties APPLICATION AREAS EF350 Bio is a flux with a wide...

Open the catalog to page 8

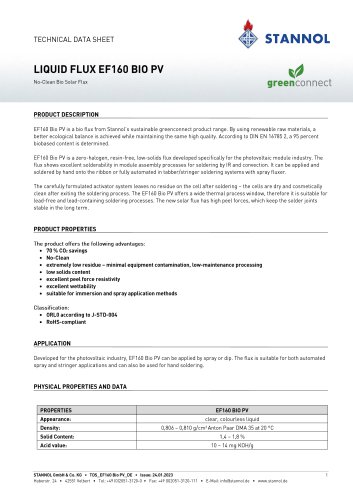

SOLAR FLUXES – EF160 BIO PV AND EF180 BIO PV EF160 Bio PV and EF180 Bio PV were specially developed for use in the photovoltaic module industry and, as No-Clean fluxes, meet all the requirements of the industry. Both fluxes are halogen- and resin-free and low in solids. EF180 Bio PV has a slightly higher solids content in comparison and has a lightly stronger activation than EF160 Bio PV. The innovative fluxes ensure very good solderability in module assembly processes for soldering by IR and convection. PRODUCT ADVANTAGES • significant CO2 savings • No-Clean • low residue – minimal...

Open the catalog to page 9

SPECIAL FLUX – AK-1 BIO The halogen-free No-clean flux AK-1 Bio was specially developed for cable tinning, tinning on component connections and soldering on copper or copper-passivated surfaces. According to DIN-EN 16785-2, a 90 percent bio-based content is determined. PRODUCT ADVANTAGES • significant CO2 savings • No-Clean • resin-free • very well suited for dipping processes • J-STD-004 (modified), class ORL0 APPLICATION AREAS AK-1 Bio is preferably applied by dipping. The application method depends on the specific use; brush and dispenser application are also suitable. Dip and wave...

Open the catalog to page 10

WATER-BASED FLUXES – WF130 AND WF131 WF130 and WF131 are developments of water-based ORL0 fluxes. Both deliver perfect soldering results and leave very low amounts of electrically harmless residues in combination with an extremely low corrosion potential. These two water-based fluxes are true halogen-free fluxes and contain no VOCs. Due to the very low corrosive potential, both can be classified as L0, which is not often possible with water-based fluxes. The main difference of the WF131 is a further reduction of the residue level, with the small trade-off of a slightly smaller process...

Open the catalog to page 11All Stannol catalogs and technical brochures

-

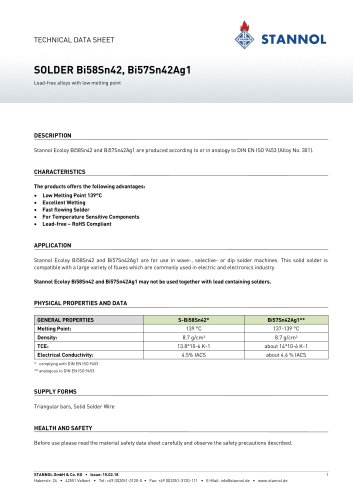

SOLDER Bi58Sn42, Bi57Sn42Ag1

2 Pages

-

LIQUID FLUX EF160 BIO PV

2 Pages

-

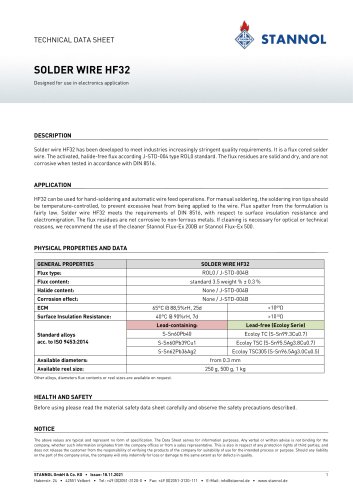

HF32

1 Pages

-

SP6000

3 Pages

-

Main Catalogue 2024

17 Pages