Catalog excerpts

Your Threaded Fastening Solution Self-Clinching Fasteners & Threaded Inserts Product Specifications AS/EN/JISQ9100 - Revision B and ISO 9001:2008 Certificate Number: AS-1092b

Open the catalog to page 1

Internal Locking Thread Form On the following pages you will find information on the non-standard Spiralock Fastener Products, which are made to order, with the exception of several sizes of self-clinching nuts that are currently in stock. If for any reason your required size is not listed in this catalog, please contact our offices at (800) 521-2688 or send an email to slinfo@spiralock.com. We are able to supply and/or design any fastener your application may require. For additional information on Spiralock technology, products and applications, please visit our website, www.spiralock.com....

Open the catalog to page 2

Product Introduction Spiralock Corporation has re-engineered the standard (female) internal thread form and added a unique 30degree wedge ramp at the root of the thread. This unidirectional internal thread form, called Spiralock®, mates with standard 60-degree male thread fasteners. The wedge ramp allows the bolt to spin freely relative to the female threads until clamp load is applied. At that point, the crests of the standard male thread form are drawn tightly against the wedge ramp, eliminating radial clearances and creating a continuous spiral line contact along the entire length of the...

Open the catalog to page 3

Things to Know About the Spiralock Thread Form MATES WITH STANDARD MALE FASTENER The Spiralock thread form is designed to mate with standard 2A/3A fractional, 4g6g or 6g metric or UNJ-MJ male fasteners. TORQUE/TENSION RELATIONSHIP The Spiralock thread form design creates a helical line of contact between the crest of the bolt threads and its 30-degree wedge ramp. In order to generate similar joint tension as compared to 60-degree threads, the Spiralock threaded joint generally requires 10% - 20% greater torque due to the redirecting of some assembly forces from an axial direction to a...

Open the catalog to page 4

Things to know about the Spiralock Thread Form LOAD DISTRIBUTION Research studies performed by Lawrence Livermore National Laboratory, Massachusetts Institute of Technology and others have confirmed that the load carried by Spiralock threads is much more uniform than the standard 60-degree threads. Additionally, they show that the percentage of load on the first engaged thread produced with a Spiralock tap is significantly lower, 24% versus 64% with five thread engagement. Spiralock Thread Standard 60º Thread The uniform loading eliminates the load concentration at the first engaged thread,...

Open the catalog to page 5

Fastener Product Offering Products Options #2 to 4” M2 to M100 Clear Zinc Chromate (standard) Others upon request - Grade 5 or 8, PC 9 or 10 - Stainless Steel - Small Production Runs - Made to std: SAE/IFI/ASTM - Exotic materials - Nickel-base alloys #4-40, #6-32, #8-32, #10-32, ¼-20 Styles Surface Coatings/Platings/ Material types Stainless Steel Pilot length #2 to ½” M2 to M12 Brass Steel Stainless Steel Zinc Plate (steel) Sizes * Standard: Hex Flange Nuts Made to order: 12 Point, Weld, Spanner, T-slot Channel, Extension Stocked SelfClinching Nuts Made to order SelfClinching Nuts Floating...

Open the catalog to page 6

Self-Clinching Fasteners For PC Boards There are a variety of fasteners to satisfy component-to-board, board-to-board and board-to-chassis production fastening needs. These fasteners are designed for use with all types of printed circuit boards, as well as acrylic, polycarbonate and aluminum panels. Once pressed into PC boards, they offer permanent threads for board mounting or component attachment. Thread Size EDP # A Max. Hole Size in Sheet * C E T 0.060 Minimum Sheet Thickness 0.060 0.147 0.165 0.219 0.065 Min. Dist. Hole C/L To Edge 0.16 2-56 92500 4-40 92505 0.060 0.060 0.166 0.184...

Open the catalog to page 12

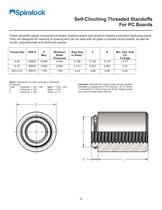

Self-Clinching Threaded Standoffs For PC Boards These standoffs satisfy component-to-board, board-to-board and board-to-chassis production-fastening needs. They are designed for stacking or spacing and can be used with all types of printed circuit boards, as well as acrylic, polycarbonate and aluminum panels. Thread Size EDP # A Max. Hole Size in Sheet * C E 0.060 Minimum Sheet Thickness 0.060 0.166 0.184 0.219 Min. Dist. Hole C/L To Edge 0.17 4-40 92600 6-32 92605 0.060 0.060 0.213 0.231 0.281 0.22 M3 x 0.5 92610 1.50 1.50 4.20 4.68 5.56 4.40 Notes: Dimensions for metric sizes are in...

Open the catalog to page 13

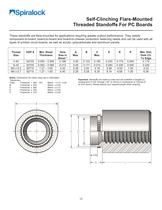

Self-Clinching Flare-Mounted Threaded Standoffs For PC Boards These standoffs are flare-mounted for applications requiring greater pullout performance. They satisfy component-to-board, board-to-board and board-to-chassis production fastening needs and can be used with all types of printed circuit boards, as well as acrylic, polycarbonate and aluminum panels. Thread Size EDP # Min. Sheet Thickness 4-40 6-32 M3 x 0.5 M4 x 0.7 92700 92705 92710 92715 0.050 – 0.065 0.050 – 0.065 1.27 – 1.65 1.27 – 1.65 Hole Size in Sheet * 0.166 0.213 4.20 6.40 Notes: Dimensions for metric sizes are in...

Open the catalog to page 14

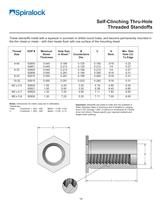

Self-Clinching Thru-Hole Threaded Standoffs These standoffs install with a squeeze in punched or drilled round holes, and become permanently mounted in the thin sheet or metal – with their heads flush with one surface of the mounting sheet. Thread Size EDP # Minimum Sheet Thickness Hole Size in Sheet * B Counterbore Dia. C H Nom. Min. Dist. Hole C/L To Edge 4-40 8-32 92800 92801 92805 92806 92810 0.040 0.040 0.040 0.050 0.050 0.166 0.213 0.213 0.281 0.281 0.125 0.125 0.156 0.156 0.188 0.165 0.212 0.212 0.280 0.280 3/16 1/4 1/4 5/16 5/16 0.23 0.27 0.27 0.31 0.31 10-32 92815 0.050 0.281 0.203...

Open the catalog to page 15

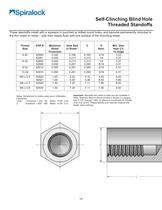

Self-Clinching Blind Hole Threaded Standoffs These standoffs install with a squeeze in punched or drilled round holes, and become permanently mounted in the thin sheet or metal – with their heads flush with one surface of the mounting sheet. Thread Size EDP # Hole Size in Sheet * C H Nom. 8-32 92900 92901 92905 92906 92910 Minimum Sheet Thickness 0.040 0.040 0.040 0.050 0.050 0.166 0.213 0.213 0.281 0.281 0.165 0.212 0.212 0.280 0.280 3/16 1/4 1/4 5/16 5/16 Min. Dist. Hole C/L To Edge 0.23 0.27 0.27 0.31 0.31 4-40 10-32 92915 0.050 0.281 0.280 5/16 0.31 M3 x 0.5 M4 x 0.7 92920 92921 92925...

Open the catalog to page 16All STANLEY Engineered Fastening catalogs and technical brochures

-

ENGINEERED FASTENING SOLUTIONS

200 Pages

-

Pro Weld Model Type AG-804

1 Pages

-

Pro Weld Model Type AG-805

1 Pages

-

Pro Weld Model Type AG-900

1 Pages

-

ARC-656

2 Pages

-

Cold formed Specials

12 Pages

-

Taptite 2000

12 Pages

-

Threaded Fasteners for Plastics

32 Pages

-

Engineered Standards®

32 Pages

-

Torx Plus

16 Pages

-

NeoSpeed

4 Pages

-

SAT Catalog EFS Europe

160 Pages

-

Octolok imperial

4 Pages

-

Lockbolt Systems

96 Pages

-

NeoBolt® Lockbolt System

12 Pages

-

SAT Catalog EFS

180 Pages

-

Speed Fastening Systems

96 Pages

-

Breakstem Riveting Systems NA

128 Pages

-

ProSert XTN20

2 Pages

-

734 AV? Series

6 Pages

-

MULTI-GRIP RIVET DATA SHEET

2 Pages

-

LS RIVET DATA SHEET

2 Pages

-

Spiralock Fastener

19 Pages

-

POP Blind Riveting Systems

68 Pages

-

HeliCoil

40 Pages

-

Heli-Coil Aftermarket Products

24 Pages

-

Tucker Emhart Plastics

8 Pages

-

POP NUT Manual & Power Tools

8 Pages

-

Heli-Coil Tangless

6 Pages

-

QA Socket Trays

2 Pages

Archived catalogs

-

Intelligent Air Tools Brochure

12 Pages

-

Air Tool Configuration Catalog

40 Pages