Website:

SST MICROWELDING

Website:

SST MICROWELDING

Group: SST France

Catalog excerpts

LASE ONE MICRO WELDING - S P O T THE ALTERNATIVE TO LASER WELDING LASE ONE ▪ Plasma arc spot welding (0 to 300 joules) ▪ Weld quality and aspect very similar to that of laser weld ▪ No overheating / deformations ▪ Easy assembly and repair welds of very small as well as large parts ▪ Weld time adjustable to the tenth of a millisecond (pulse duration 0.1 to 10 ms) ▪ Reliable and easy to use ▪ Programmable ▪ Welding of ferrous / non-ferrous / precious materials (gold, silver, etc.) ▪ Economical and safe ▪ Welding power and weld time independently adjustable TYPICAL APPLICATIONS LASE ONE technology is the solution to all your problems when it comes to complex assembly and repair micro-welding. LASE intensity with total control and pre5 mm cision, for a wide range of applications, materials and configurations. Efficient, easy to use, compact and versatile, it displays the qualities of 5 mm pulsed YAG laser welding and the benefits of an electric solution: simplicity and economy.

Open the catalog to page 1

TECHNICAL CHARACTERISTICS MODEL Maximum weld energy at output (joules) Power supply Control type Current regulation Energy settings By 1% increments of total energy Pulse duration Generator cooling Programming Adjustable external settings 9 adjustable programmes ▪ Welding power (0 to 99 %) ▪ Pulse duration (0.1 to 10 ms – by 0.1 ms increments) Maximum pulse rate Factory configuration: 4 pulses / second (300j) Weld area protection Accessories and options (*) Model-dependent Control pedal Micro-welding torch Ø 1.0 mm ; 1.6 mm ; 2.4 mm electrodes Clamp holders for Ø 1.0 mm ; 1.6 mm ; 2.4 mm...

Open the catalog to page 2All SST MICROWELDING catalogs and technical brochures

-

SPOT TIG Electrodes

3 Pages

-

Lase One - Accessories

11 Pages

-

LASE ONE Equipments

3 Pages

-

WS - Accessories

6 Pages

-

WS Equipments

2 Pages

-

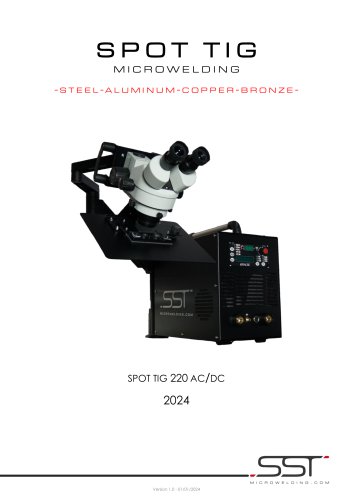

SPOT TIG

2 Pages

-

Documentation WS

2 Pages