Website:

SST MICROWELDING

Website:

SST MICROWELDING

Group: SST France

Catalog excerpts

POWERFUL - ACCURACY - FAST - SAFE WS welding stations are revolutionizing the air-cooled repair welding of tooling. Thanks to their unique medium frequency technology, they combine a disconcerting ease of use with excellent quality results and productivity. With a rate of 50 pulses per second, a very high maximum power, millisecond-long welds and extremely precise current regulation, they enable you to obtain optimal weld quality, very close to laser quality, be it in terms of aspect or resistance, even to extreme stress (shock, shear, pressure, thermal shock, erosion, etc.). WS micro-welding devices are the perfect solution for fast, simple and long-lasting quality repair welds of the following tooling: ▪ ▪ ▪ ▪ ▪ ▪ ▪ ▪ ▪ Rubber injection Plastic injection Compression Aluminum foundry Zamak foundry Extrusion Cutting Embossing Blowing Compact Adjustable Fully cooled User friendly TYPICAL APPLICATIONS MACRO-ETCH TEST OF A WELD Identification : material 3144 ▪ 3144 part ▪ Repair weld on a 3144 ribbon ▪ Etch type: Nital ▪ Magnification : x 18 Carried out by the ECCI laboratory - Landmark trial 99.0117/2 RESULTS Structural detail in the bonding area: ▪ Satisfactory penetration of the molten metal View of assembly weld on polished metal : ▪ A few folds can be detected on the surface Angles / Corners

Open the catalog to page 1

TECHNICAL CHARACTERISTICS MODEL Power supply Converter type Maximum welding power (1) Maximum welding current (2) Open circuit voltage U20 Control type Current regulation Maximum weld time Minimum weld time Current precision Generator cooling Cable cooling Forced air through fast electric connection / compressed air through cone Adjustable settings Maximum pulse rate Maximum welding capacity (3) (1) Measured at standard cable ends W elding current in % W eld time in milliseconds W eld cycle / shoot mode (Single - or multi-point) Pulse form (Powder / W ire - Ribbon) 50 1.2 / 0.4 Rotating...

Open the catalog to page 2All SST MICROWELDING catalogs and technical brochures

-

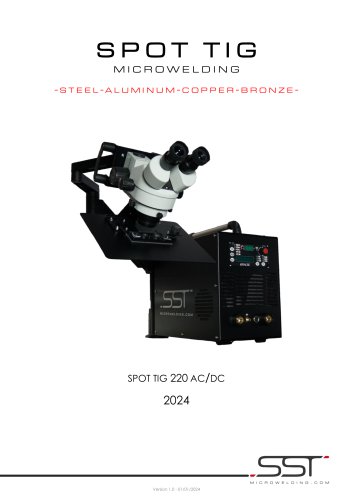

SPOT TIG Electrodes

3 Pages

-

Lase One - Accessories

11 Pages

-

LASE ONE Equipments

3 Pages

-

WS - Accessories

6 Pages

-

WS Equipments

2 Pages

-

SPOT TIG

2 Pages

-

LASE ONE documentation

2 Pages