Website:

SSR TRADE

Website:

SSR TRADE

Catalog excerpts

Conveyor Filter Systems -The UNIFIL series Conveyor filters will effectively remove particles in your industrial fluids such as: • Sewerage water. • Wastewater. • Coolant and lubricants. • Chemical process fluids. • Painting canins. • Pretreatment applications. Conveyor filter advantages: • Particles and steam filter is separated. • Effective filtration ensures less production stops and lower running costs. • Fluid or particles can be recycled in the process or removed. • Bad smell and chances of infections from dirty fluids are minimized. • 100 % use of steam filter. • Filtering down to 10 m#. • Fully automatic. • Easy to install, very little maintenance. Function: The Conveyor filter is build on the principal of mechanical filtering, where a fluid column secures the needed pressure for filtering. The filter is as standard constructed in stainless steel. The Conveyor filter system is easily installed in existing machinery og industrial applications. It is constructed to function continiously for many years– effectively removing unwanted particles. The capasity depends on the fluid viscosity, the level of filtration and the particle content in the fluid. From the inlet the fluid is spread throughout the filter cloth. The fluid is pushed through the filter cloth where the particles are withheld If there is an increasing level of fluid as a result of a soiled filter cloth, a new clean piece of filter cloth will be activated from the roll automatically. With this method, the filtercake will be pulled out of the machine and dried before it is scraped off by the collector. The used filter cloth will be rolled out separately for easy removal. Tanks can be made on you request in all sizes but is only availible in stock in standard sizes, matching the dimensions of the conveyor filter system—prepared for mounting of pump. The tanks contains as standard the nessecairy coverplates, drainage valves etc. for optimum performance. Bottomframe under the tanks is not standard. UNIFIL: Conveyor filter system with side inlet, tank and receptacle to collect the sludge. Technical Features: * Height includes top inlet. ** Capasity at 20°C with one filter cloth (P60) and a fluid viscosity of 1cSt. *** Capasity at 20°C with one filter cloth (P60) and a fluid viscosity of 12cSt. Electrical input : 3 x 400 VAC, 50 Hz Control voltage : 24 VAC, 50 Hz Standard control : 3 point switch for automatical-0-manual ope ration : Reset of gear motor : Indicator for filter cloth : 24 Volt output Receptacle : Standard Inlet types : Top inlet (standard) : Side inlet Conveyor Filter Systems Length [mm] Width [mm] Heigth [mm]* UNIFIL 250 980 450 570 UNIFIL 500 980 700 570 UNIFIL 700 980 900 570 UNIFIL 1000 980 1200 570 UNIFIL SE 1000 1980 1200 680 Weight [kg] Capasity [l/min]** Capasity [l/min]*** UNIFIL 250 65 80 50 UNIFIL 500 75 150 90 UNIFIL 700 90 250 150 UNIFIL 1000 110 400 250 UNIFIL SE 1000 145 800 500 SSR TRADE Sundparken 7 DK-3600 Frederikssund Denmark Tel. +45 29922965 Fax +45 47316610 www.ssr-trade.com info@ssr-trade.com

Open the catalog to page 1All SSR TRADE catalogs and technical brochures

-

Band Lenghts

2 Pages

-

Unifil 250

1 Pages

-

Unifil 250 with tank

1 Pages

-

Unifil 500

1 Pages

-

Unifil 500 with tank

1 Pages

-

Unifil 700

1 Pages

-

Unifil 700 with tank

1 Pages

-

Unifil 1000 with tank

1 Pages

-

Unifil SE 1000 with tank

1 Pages

-

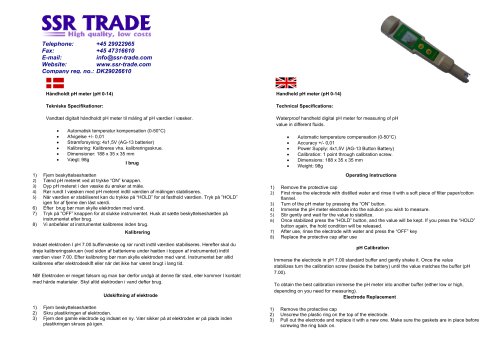

Digital Handheld pH meter

1 Pages

-

SSR-Switch H

1 Pages

-

SSR-Switch V

1 Pages

-

Refractometer for Emulsions

1 Pages

-

Skim Magnetic

1 Pages

-

Skim Stationary Mini

1 Pages

-

Skim Stationary Deluxe

1 Pages

-

Oil Buster

1 Pages

-

Skim Stationary

1 Pages

-

liquid level switch

1 Pages

-

digital pH meter

1 Pages

-

Brake fluid testing

1 Pages

-

oil skimmer (universal)

1 Pages