Catalog excerpts

SH©CKWATCH* ShockWatch® Flex SMART SOLUTIONS FOR SAFE TRANSIT ShockWatch Flex incorporates the proven technology of the ShockWatch impact indicator label in a flexible format. Even irregular shaped items can benefit from knowing that mishandling has occurred. The design process is a delicate one. In many industries, fractions of millimeters can be the difference between success and a return to the drawing board. When designing items like aircraft components, medical equipment or laser systems, precision is key. So how do you know if the tools you are using to design and build your product are within tolerance? If they have been dropped, are they still measuring correctly? The ShockWatch Flex can assist you in knowing what happened to your equipment when it was out of sight. Was the caliper dropped? Does it need recalibration if it did? Is it worth the The ShockWatch Flex is a highly visible impact indicator that alerts you if your product has been subjected to unacceptable handling. Based on ShockWatch's proprietary impact sensing technology, the Flex is optimal when mounting an impact indicator complicated by product shape. The Flex can be mounted easily to curved and irregular shapes, ensuring the indicator will remain in place. The Flex is ideal for monitoring tools that may become misaligned, equipment that may lose their calibration, or products that may be damaged with mishandling. • Provides indisputable evidence of mishandling • Acts as a visual deterrent to improper handling • Promotes chain of accountability for all product handling • Confirms effectiveness of packaging SHOCKWATCH' FLEX SH©CKWATCH FLEX

Open the catalog to page 1

ShockWatch® Flex Selection Guide Selection of the appropriate ShockWatch Flex begins with understanding the product to be monitored. To select the proper activation levels, determine if shock specifications exist for the product to be monitored. Most complex electromechanical products such as hard drives, avionics, analysis instruments, etc. have been through extensive testing to establish shock damage boundary data. Activation graphs are available for the Flex to help match the damage characteristics of your product. The ShockWatch Flex is available in single and double tube...

Open the catalog to page 2All SpotSee catalogs and technical brochures

-

SpotBot 4G Plus Overview

3 Pages

-

SpotSee® Tilt Indicators

2 Pages

-

ShockLog 248

2 Pages

-

Tilt Indicators

2 Pages

-

Forehead Thermometer

2 Pages

-

ShockWatch RFID Overview

2 Pages

-

TempU

1 Pages

-

SpotBot™ Cellular

2 Pages

-

LOGIC Temperature Recorder

2 Pages

-

ColdMark

1 Pages

-

WarmMark Overview

2 Pages

-

OpsWatch Overview

3 Pages

-

ShockWatch Tube

2 Pages

-

ShockWatch Flex

2 Pages

-

Mag-2000

2 Pages

-

ShockWatch Label

2 Pages

-

ShockDot

2 Pages

-

ShockLog Cellular

2 Pages

-

SpotBot BLE

1 Pages

-

SpotBot Cellular

2 Pages

-

Temperature Recorders

2 Pages

-

Cold Chain Indicators

2 Pages

-

Blood Temp 10

1 Pages

Archived catalogs

-

2018 ShockWatch Clip

2 Pages

-

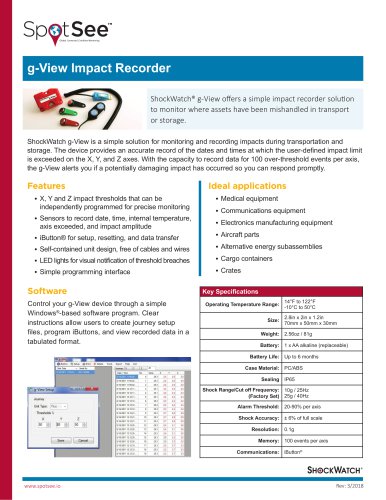

2018 g-View Impact Recorder

1 Pages

-

2018 ShockTrak™ Overview

2 Pages

-

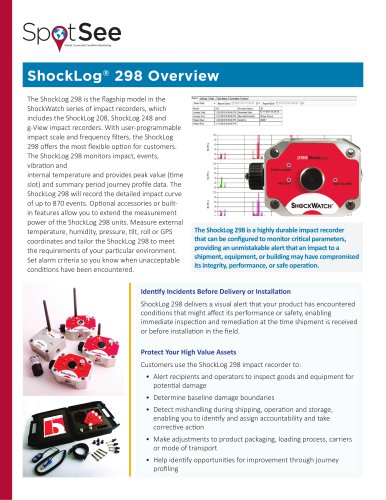

2018 ShockLog® 298 Overview

4 Pages

-

Seafood Indicator

1 Pages

-

Impact Recorders

2 Pages

-

ShockWatch Labels

2 Pages

-

2016 g-View Impact Recorder

1 Pages

-

ShockLog 208

2 Pages

-

OpsWatch

2 Pages

-

2016 ShockWatch Clip

2 Pages

-

ShockWatch® MAG 2000

2 Pages

-

ShockDot Impact Indicator

2 Pages