Catalog excerpts

Automotive Manufacturing: ShockWatch RFID Case Study

Open the catalog to page 1

Automotive Manufacturing: ShockWatch RFID Case Study Industry: Automotive Manufacturing Application: Automotive manufacturers move a large number of delicate parts through their supply chain such as headlights, instrument panels, glass, calibrated equipment, brazed radiators, etc. Challenge: A major automotive manufacturer was experiencing a high rate of internal supply chain damage to parts moving from plant to plant and within their warehouses. The company needed a cost-effective solution that could track individual product damage and alert supply chain managers of the damage before the...

Open the catalog to page 2

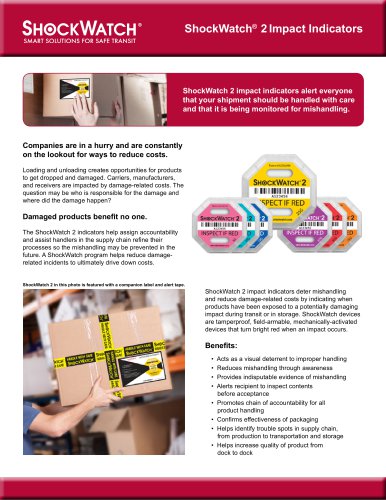

ShockWatch 2 Impact Indicators Automotive Manufacturing: ShockWatch RFID Case Study Extend the power of your RFID program byindicators alert everyone ShockWatch 2 impact monitoring for damage that your shipment should be handled with care Every company wants to improve their supply chain processes. RFID and that it is being monitored for mishandling. technology aided companies in improving inventory control. The ShockWatch RFID impact indicator allows companies to leverage the inventory tracking benefits of RFID and the benefits of an impact monitoring program. With and are constantly...

Open the catalog to page 3All SpotSee catalogs and technical brochures

-

SpotBot 4G Plus Overview

3 Pages

-

SpotSee® Tilt Indicators

2 Pages

-

ShockLog 248

2 Pages

-

Tilt Indicators

2 Pages

-

Forehead Thermometer

2 Pages

-

ShockWatch RFID Overview

2 Pages

-

TempU

1 Pages

-

SpotBot™ Cellular

2 Pages

-

LOGIC Temperature Recorder

2 Pages

-

ColdMark

1 Pages

-

WarmMark Overview

2 Pages

-

OpsWatch Overview

3 Pages

-

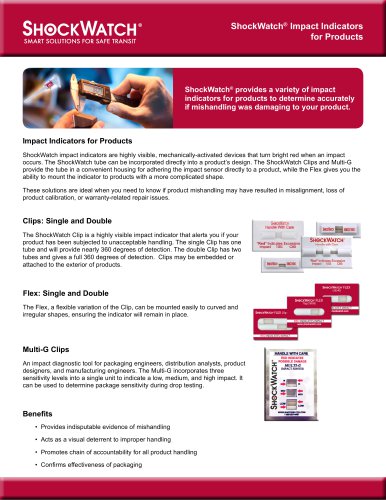

ShockWatch Tube

2 Pages

-

ShockWatch Flex

2 Pages

-

Mag-2000

2 Pages

-

ShockWatch Label

2 Pages

-

ShockDot

2 Pages

-

ShockLog Cellular

2 Pages

-

SpotBot BLE

1 Pages

-

SpotBot Cellular

2 Pages

-

Temperature Recorders

2 Pages

-

Cold Chain Indicators

2 Pages

-

Blood Temp 10

1 Pages

Archived catalogs

-

2018 ShockWatch Clip

2 Pages

-

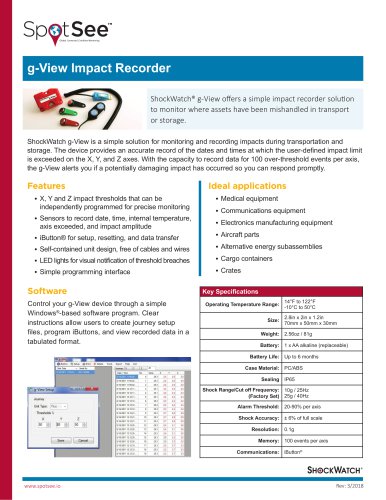

2018 g-View Impact Recorder

1 Pages

-

2018 ShockTrak™ Overview

2 Pages

-

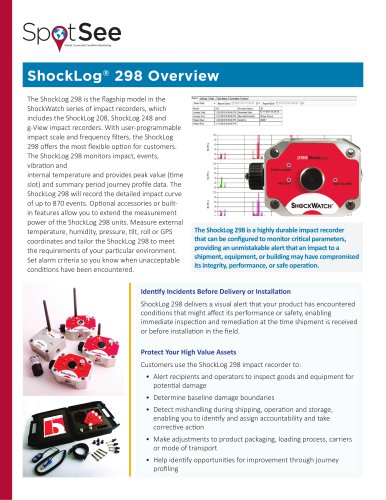

2018 ShockLog® 298 Overview

4 Pages

-

Seafood Indicator

1 Pages

-

Impact Recorders

2 Pages

-

ShockWatch Labels

2 Pages

-

2016 g-View Impact Recorder

1 Pages

-

ShockLog 208

2 Pages

-

OpsWatch

2 Pages

-

2016 ShockWatch Clip

2 Pages

-

ShockWatch® Flex

2 Pages

-

ShockWatch® MAG 2000

2 Pages

-

ShockDot Impact Indicator

2 Pages