Website:

SPIROL

Website:

SPIROL

Catalog excerpts

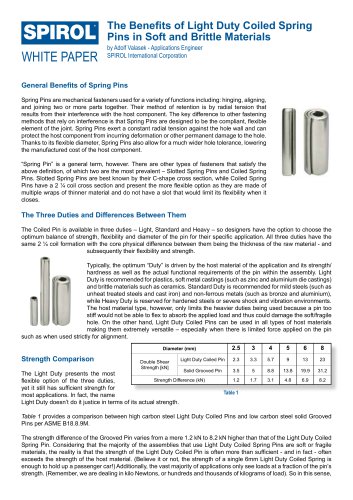

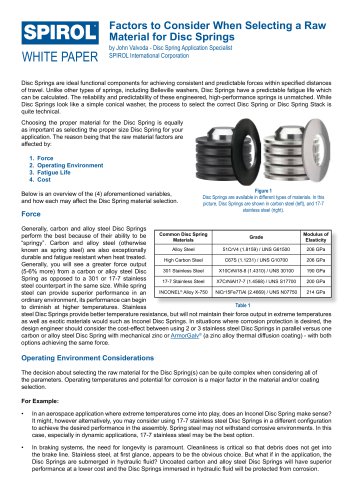

Which Austenitic Stainless Steel Spring Pin is Best for WHITE PAPER Dynamic Loading? by Michael Pasko, Engineer SPIROL International Corporation Austenitic nickel stainless steel Spring Pins are typically manufactured from grade SAE 302/304 (18-8 (1.4310)). The chemical and physical properties of these grades overlap and most mills produce material that can be certified as either. Austenitic stainless steel is often selected for corrosion resistance or cost reduction. While this material possesses the spring characteristics required for proper insertion, retention, and performance, it introduces potential issues that must be considered in design. The Coiled Pin offers many advantages when compared to Slotted Pins and some are most evident in austenitic stainless steel. While austenitic stainless steel is ideal in some applications, particularly those requiring high levels of corrosion resistance, it may not be suitable in critical applications where the pin is subject to dynamic loading. This is true of Coiled and Slotted Pins as this material work hardens rapidly. Though mills use work hardening to achieve high yield strength, it is critical to understand this is a continuous process. As yield strength increases, ductility decreases. In dynamic applications vibration, impact and movement will continue work hardening the pin at a rate commensurate with severity and frequency. Excessive work hardening of austenitic stainless steel can lead to fatigue failure evident as cracking or loss of retention. Though both Coiled and Slotted Pins will work harden, the Coiled Pin’s superior design provides improved endurance under these conditions. All Spring Pins are designed with a pre-installed diameter larger than the recommended hole. Slotted Pins are manufactured with a gap that allows compression of the pin during installation. This differs from Coiled Pins that are designed with a seam (and no gap). Once installed, a Spring Pin is held in tension and this provides retention. A Spring Pin may also maintain desired fit and function by dampening vibration and shock which prevents damage and/or deformation of the host hole. A Slotted Pin can only flex along its spine 180° opposite the gap, much like opening and closing a book. This focuses all stress in one location (see Figure 2) leading to rapid fatigue and potential cracking (see Figure 3). Similarly, once the metal has lost ductility it can no longer recover to maintain tension within the hole and retention can be compromised. Figure 1: Slotted Pin and Coiled Pin Figure 2: High stress area of a Slotted Pin Figure 3: A Slotted Pin can only flex along its spine 180° opposite the gap, much like opening and closing a book. Comparatively, Coiled Pins spread compressive stress over the entire pin and do not have stress point concentrations. Under applied loads, the Coiled Pin continues to flex and coil toward the center, absorbing shock and vibration, distributing the load throughout the cross section shown in Figure 4. The Coiled Pin is effectively locked at the seam and movement occurs through the inner coil. This serves two important purposes; the stress is distributed evenly through the pin’s cross-section and the pin remains round to maintain maximum contact with the hole wall. Figure 4: Flexibility under load of a Coiled

Open the catalog to page 1

The following photographs demonstrate fundamental differences in design. In Figure 5 is a Slotted Pin installed in the nominal recommended hole. Minimal gap remains yet movement is still possible. This may serve to delay work hardening and fatigue - though it will still occur. In this example, once the Slotted Pin is fully compressed under load the seam butts and it will function as a solid tube. This can damage the hole. In Figure 6, the Slotted Pin is installed in an oversized hole. In this instance there is greater potential for movement since the gap is wider and fatigue can occur more...

Open the catalog to page 2

Innovative fastening solutions. Lower assembly costs. Slotted Spring Pins Coiled Spring Pins Solid Pins Compression Limiters Dowel Bushings / Spring Dowels Rolled Tubular Components Precision Washers Precision Shims & Thin Metal Stampings Disc Springs Installation Technology Parts Feeding Technology Please refer to www.SPIROL.com for current specifications and standard product offerings. SPIROL Application Engineers will review your application needs and work with you to recommend the optimum solution. One way to start the process is to visit our Optimal Application Engineering portal at...

Open the catalog to page 3All SPIROL catalogs and technical brochures

-

Alignment Dowels/Bushings

12 Pages

-

Compression Limiter Design Guide

20 Pages

-

Slotted Spring Pins

16 Pages

-

Latch Pins for Plastics

2 Pages

-

Railroad Nuts - AAR Series

2 Pages

-

SPIROL Corporate Brochure

12 Pages

-

Disc Springs

20 Pages

-

Coiled Spring Pins

24 Pages

-

Series RH600 Twist-Lok™ Pins

2 Pages

-

Cosmestic Pins 550 series

2 Pages

-

Installation Technology

8 Pages

-

SPIROL Precision Shims

8 Pages

-

Medical Device Applications

2 Pages

-

SPIROL Solid Pins Catalog

12 Pages

-

Series 2000 Series 2000

4 Pages

-

Aerospace Applications Flyer

2 Pages

-

PH series PH series

2 Pages

-

HC series HC series

2 Pages

-

Tables Standard

2 Pages

-

Tables Lift and Roll

2 Pages

-

SPD, CXA, CXD, CXE CRD

2 Pages

-

880 Series

2 Pages