Website:

SPIROL

Website:

SPIROL

Catalog excerpts

SLOTTED SPRING PINS

Open the catalog to page 1

WHAT ARE SLOTTED SPRING PINS? Slotted Spring Pins are general purpose components used in various fastening applications. Compressed as it is installed, the pin applies continuous pressure on the sides of the hole wall. The primary spring action of the Slotted Pin is focused on the area opposite the slot as the two halves of the pin compress during installation. This flexibility allows Slotted Spring Pins to accommodate wider hole tolerances than rigid Solid Pins which results in reduced manufacturing costs of the mating component. WHY SPIROL® SLOTTED PINS ARE THE PINS OF CHOICE • SPIROL...

Open the catalog to page 2

• SPIROL has over 75 years of experience in producing quality pins with full lot traceability back to the raw material. Raw materials are RoHS, REACH, Conflict Mineral, and DFARS compliant. • SPIROL has a global footprint with a physical presence in the US, Canada, Mexico, Brazil, England, France, Germany, Spain, Poland, Czech Republic, China and South Korea. • SPIROL’s production facilities are IATF 16949, ISO 9001, and ISO 14001 certified. The customer is assured that each shipment is from the same source produced on the same equipment to the highest quality standard. • SPIROL is a direct...

Open the catalog to page 3

STANDARD SLOTTED SPRING PINS SPECIFICATIONS & TECHNICAL DATA B High Carbon Steel C Martensitic Stainless Steel D Austenitic Stainless Steel *Austenitic stainless steel pins are not oiled. IDENTIFICATION CODE Slotted Pin 6mm diameter x 32mm length carbon steel/plain finish SLTP K Second letter specifies finish First letter specifies material Second figure specifies length First figure specifies nominal diameter Prefix specifies pin type HOW TO MEASURE THE DIAMETER OF A SLOTTED SPRING PIN SPIROL Standard Slotted Pins are manufactured and inspected to be within diameter specifications along...

Open the catalog to page 4

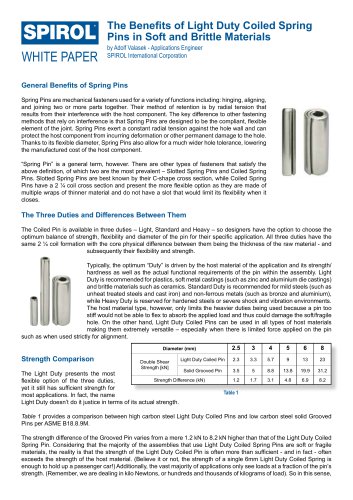

SLOTTED PIN SPECIFICATIONSSTANDARD METRIC Chamfer both ends. Contour of chamfer optional. DESIGNED FOR AUTOMATIC FEEDING AND INSTALLATION Length Tolerance Over 24mm to 50mm incl. ± 0.50mm Over 50mm to 75mm incl. ± 0.60mm Available in high carbon (B) and stainless steel (C, D) Only available in high carbon (B) Generally stocked size 1 Shear tests performed in accordance with ASME B18.8.4M & ISO 8749 2 The straightness over the length of the pin shall be such that the pin will pass freely through a ring gauge of the length and diameter specified. • All dimensions apply prior to plating •...

Open the catalog to page 5

SLOTTED PIN SPECIFICATIONSISO 8752 METRIC METRIC SPECIFICATIONS NOMINAL . Only available in high carbon (B) and austenitic stainless steel (D) Only available in high carbon (B) Generally stocked size 1 Shear tests performed in accordance with ISO 8749. Shear strength for austenitic stainless steel is not specified. • Other sizes and materials available to order

Open the catalog to page 6

SLOTTED PIN SPECIFICATIONSSTANDARD INCH LENGTH tr DESIGNED FOR AUTOMATIC FEEDING AND INSTALLATION Chamfer both ends. Contour of chamfer optional. INCH SPECIFICATIONS NOMINAL DIAMETER Available in high carbon (B) and stainless steel (C, D) Generally stocked size 1 Shear tests performed in accordance with ASME B18.8.2. 2 The straightness over the length of the pin shall be such that the pin will pass freely through a ring gauge of the length and diameter specified. • All dimensions apply prior to plating • Other sizes and materials available to order • ASME B18.8.2 is based on SPIROL's...

Open the catalog to page 7

STANDARD MATERIALS TYPE CARBON STEELS Carbon steels are the most cost effective and versatile materials available for use in Slotted Spring Pins. These materials are readily available, easy to process, and have very uniform and predictable performance characteristics. The most noticeable limitation to these materials is corrosion protection. In most applications, the normal rust preventative oil is adequate for corrosion protection. In cases where extra protection is necessary, the benefits of supplemental coatings and stainless steel must be evaluated. High Carbon Steel (B) High carbon...

Open the catalog to page 8

Protective finishes are generally used to improve the corrosion resistance of the base metal. There are many different coating types, such as electroplating, chemical conversion, immersion, and mechanical applications. Each of these processes has limitations when applied to Slotted Spring Pins and depending on the application there may be other concerns. SPIROL has extensive experience in recommending and selecting the right combination of material and finish for a variety of applications. Given the propensity for ISO Slotted Pins to interlock during processing, only SPIROL Standard Slotted...

Open the catalog to page 9

SHEAR PROPERTIES WHAT IS SHEAR STRENGTH? The shear strength of a Slotted Pin is determined by the maximum amount of force the pin can withstand before it breaks when the force is applied perpendicular to the axis of the pin. Pins can be sheared in multiple planes, for example, a pin that breaks in single shear would result in two separate pieces of the pin, whereas a pin that breaks in double shear would result in three separate pieces of the pin. The three prevailing industry standards (ASME, ISO, and JIS) specify a minimum shear strength for Slotted Spring Pins and specific parameters...

Open the catalog to page 10

DESIGN GUIDELINES LOCATING AND ALIGNMENT DESIGN SHAFT DESIGN To achieve optimal alignment when using Slotted Pins, two primary design elements must be adhered to: 1) The hole diameters in the host and mating component must be sized accordingly to achieve the desired interference and accuracy of alignment. 2) In all applications, the engagement length of the Slotted Pin in the component providing primary retention must be no less than 60% of the pin’s overall length. The remaining protruding length will align with the mating component. Increasing the initial length of engagement is...

Open the catalog to page 11

DESIGN GUIDELINES HINGE DESIGN HOLE DESIGN There are two primary types of hinges: 1) a free fit hinge has little to no friction or drag when the latch or handle is rotated. Hinge components are “free” to rotate independent of one another, and 2) a friction fit hinge requires interference to prevent free rotation of components relative to one another. Depending on design intent, resistance can vary from a slight drag to a value sufficient to maintain the fixed position of components anywhere in their full range of rotation. It is important to note that the recommended hole sizes (on pages...

Open the catalog to page 12All SPIROL catalogs and technical brochures

-

Alignment Dowels/Bushings

12 Pages

-

Compression Limiter Design Guide

20 Pages

-

Latch Pins for Plastics

2 Pages

-

Railroad Nuts - AAR Series

2 Pages

-

SPIROL Corporate Brochure

12 Pages

-

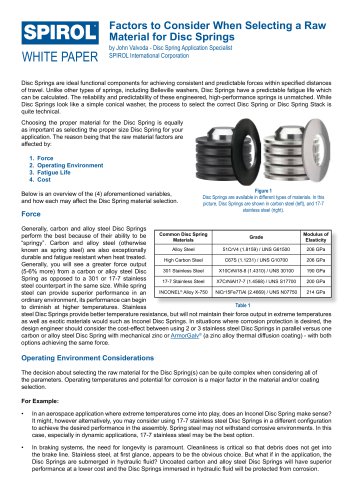

Disc Springs

20 Pages

-

Coiled Spring Pins

24 Pages

-

Series RH600 Twist-Lok™ Pins

2 Pages

-

Cosmestic Pins 550 series

2 Pages

-

Installation Technology

8 Pages

-

SPIROL Precision Shims

8 Pages

-

Medical Device Applications

2 Pages

-

SPIROL Solid Pins Catalog

12 Pages

-

Series 2000 Series 2000

4 Pages

-

Aerospace Applications Flyer

2 Pages

-

PH series PH series

2 Pages

-

HC series HC series

2 Pages

-

Tables Standard

2 Pages

-

Tables Lift and Roll

2 Pages

-

SPD, CXA, CXD, CXE CRD

2 Pages

-

880 Series

2 Pages