Website:

SPIROL

Website:

SPIROL

Catalog excerpts

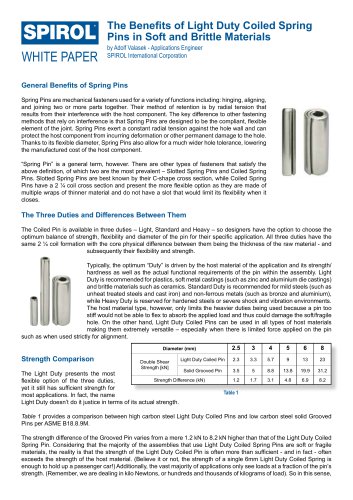

WHITE PAPER How to Select the Proper Spacer for Your Assembly by Tom Buchta, President and Tubular Products Director SPIROL Industries Ltd., Windsor, Ontario, Canada There are many different types of components that can be used as spacers, standoffs, distance bushings and sleeves. Popular options include cut-off tubing, tubes, ferrules, grommets, and machined parts. A low cost alternative to these more expensive options are Roll Formed Tubular Spacers. SPIROL offers metal Tubular Spacers in two standard wall thicknesses, SP100 Standard Wall and SP150 Heavy Wall, to accommodate specific application strength and bearing requirements. As the name implies, the SP100 Standard Wall Spacer has a thinner wall thickness compared to the SP150 Heavy Wall Spacer. Often used in conjunction with a bolt, Tubular Spacers are designed to provide a clearance fit over standard bolt and screw sizes. Columnar strength is a primary consideration when determining whether to use the SP100 Standard Wall or SP150 Heavy Wall Spacer. In addition to having a higher columnar strength, Design Engineers may prefer the SP150 Heavy Wall Spacer as the thicker wall makes it more robust, enabling it to withstand a higher clamping load than the SP100 Standard Wall Spacer. Other applications may require the thicker wall for the larger bearing surface for distribution of the clamp load on the mating surfaces. This is particularly beneficial to prevent indenting of the material when the Spacer is clamped between two soft materials. As a general rule of thumb, SPIROL’s roll formed Spacers have about 70% of the columnar strength of cut pipe or tubing of similar size, material and wall thickness. (Variation in wall thickness and material types have significant effects on overall performance). For lighter duty applications where clamp loads are less and the larger bearing surface is not required, it is recommended to use the SP100 Standard Wall series. In addition to costing less, the SP100 Standard Wall Spacer also reduces the weight of the overall assembly since it contains less material than the SP150 Heavy Wall Spacer. The savings that companies realise through using SPIROL Roll Formed Spacers rather than more expensive spacing options is achieved through SPIROL’s proprietary roll forming technology that allows production at high speeds with no need for secondary deburring the ends of the Spacers after forming like with cut tubing. In addition, while SPIROL offers Spacers with distinct diameter and length combinations from stock, intermediate lengths can be produced quickly, without any special tooling costs. SPIROL’s Application Engineers are ready to assist you in selecting the most appropriate Roll Formed Spacer for your specific application. Difference in material thickness between SP100 Standard Wall (left) and SP150 Heavy Wall (right) Flange Hinge application with bolt passing through Spa

Open the catalog to page 1

Innovative fastening solutions. Lower assembly costs. Technical Centres Europe SPIROL United Kingdom Coiled Spring Pins Alignment Dowels / Bushings Slotted Spring Pins Spacers & Rolled Tubular Components Solid Pins Compression Limiters Threaded Inserts for Plastics Railroad Nuts Disc Springs Americas SPIROL International Corporation Precision Shims & Thin Metal Stampings Precision Washers Parts Feeding Technology SPIROL Canada 3103 St. Etienne Boulevard Windsor, Ontario N8W 5B1 Canada Tel. +1 519 974 3334 Fax. +1 519 974 6550 SPIROL Mexico Avenida Avante #250 Parque Industrial Avante...

Open the catalog to page 2All SPIROL catalogs and technical brochures

-

Alignment Dowels/Bushings

12 Pages

-

Compression Limiter Design Guide

20 Pages

-

Slotted Spring Pins

16 Pages

-

Latch Pins for Plastics

2 Pages

-

Railroad Nuts - AAR Series

2 Pages

-

SPIROL Corporate Brochure

12 Pages

-

Disc Springs

20 Pages

-

Coiled Spring Pins

24 Pages

-

Series RH600 Twist-Lok™ Pins

2 Pages

-

Cosmestic Pins 550 series

2 Pages

-

Installation Technology

8 Pages

-

SPIROL Precision Shims

8 Pages

-

Medical Device Applications

2 Pages

-

SPIROL Solid Pins Catalog

12 Pages

-

Series 2000 Series 2000

4 Pages

-

Aerospace Applications Flyer

2 Pages

-

PH series PH series

2 Pages

-

HC series HC series

2 Pages

-

Tables Standard

2 Pages

-

Tables Lift and Roll

2 Pages

-

SPD, CXA, CXD, CXE CRD

2 Pages

-

880 Series

2 Pages