Website:

SPIROL

Website:

SPIROL

Catalog excerpts

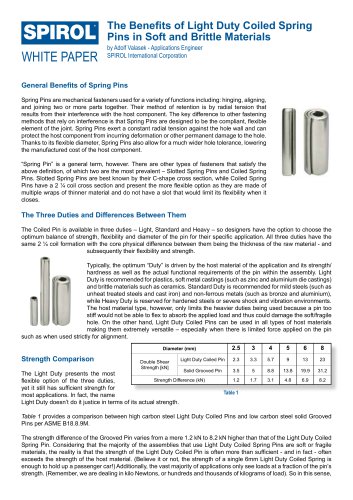

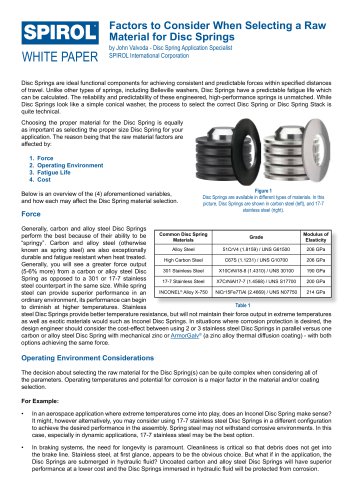

WHITE PAPER How to Design the Proper Hole for Heat / Ultrasonic Inserts by Christie Jones, Director of Marketing, Vice President SPIROL International Corporation Threaded Inserts for Plastics allow designers to replace machined and cast metal components with plastic to achieve significant cost and weight savings while maintaining bolted joint strength – provided that: 1. the proper Insert is selected for the application requirements, 2. the Insert is properly installed into the hole, and 3. the hole in which the Insert is used is designed correctly given the plastic composition, the selected Insert and installation method. Inserts also provide reusable threads and secure tight threaded joints. Given that Threaded Inserts are generally twice the diameter of screws, the load carrying ability of a joint that uses Inserts is increased by approximately four times the amount as when screws alone are used. Pull-out resistance can be further increased by increasing the length of the Inserts. Retention within the hole is provided by the plastic conforming to the external features of the Insert. A sufficient volume of plastic must be displaced to entirely fill these external features so that the Insert achieves maximum performance when the plastic solidifies. This White Paper focuses on the design guidelines for the holes in plastic assemblies that use Threaded Inserts installed by heat or ultrasonic equipment to ensure maximum performance is achieved. Optimum Design Guidelines: Holes for Inserts installed by heat or ultrasonics should always be deeper than the length of the Insert. The assembly screw should never bottom out in the hole as jack-out would result. The recommended minimum hole depth is the Insert length plus two (2) thread pitches. The top of the installed Insert should be flush with the surface of the plastic part with maximum protrusion from the host of 0.13mm (.005”). Correct (flush) Incorrect (above flush) Incorrect (below flush) Top of the Insert should be installed as close to flush as possible with the surface of the plastic. Counterbores are only recommended for Headed Inserts so that the top of the Insert will be flush with the surface of the plastic after installation. The diameter of the counterbore should be 0.5mm (.02”) to 1.3mm (.05”) larger than the head diameter of the Insert. The minimum counterbore depth should be specified as the thickness of the head.

Open the catalog to page 1

Correct hole size is critical. Larger holes decrease performance, while smaller holes induce undesirable stresses and potential cracks in the plastic. Undersized holes may also result in flash at the hole edge and make the Insert difficult to install. SPIROL provides the recommended hole sizes for each Insert style in the Inserts for Plastics Design Guide. The recommended holes need to be reviewed if glass / mineral fillers are used. If the filler content is equal to or greater than 15%, it is suggested to increase the hole 0.08mm (.003”), and if the content is equal to or greater than 35%,...

Open the catalog to page 2

Innovative fastening solutions. Lower assembly costs. Technical Centres Europe SPIROL United Kingdom Coiled Spring Pins Slotted Spring Pins Solid Pins Alignment Dowels / Bushings Spacers & Rolled Tubular Components Compression Limiters SPIROL Czech Republic Pražská 1847 274 01 Slaný Czech Republic Tel/Fax: +420 313 562 283 SPIROL Poland ul. Solec 38 lok. 10 00-394, Warszaw, Poland Tel. +48 510 039 345 Americas SPIROL International Corporation Threaded Inserts for Plastics Railroad Nuts Disc Springs Precision Shims & Thin Metal Stampings Precision Washers Parts Feeding Technology SPIROL...

Open the catalog to page 3All SPIROL catalogs and technical brochures

-

Alignment Dowels/Bushings

12 Pages

-

Compression Limiter Design Guide

20 Pages

-

Slotted Spring Pins

16 Pages

-

Latch Pins for Plastics

2 Pages

-

Railroad Nuts - AAR Series

2 Pages

-

SPIROL Corporate Brochure

12 Pages

-

Disc Springs

20 Pages

-

Coiled Spring Pins

24 Pages

-

Series RH600 Twist-Lok™ Pins

2 Pages

-

Cosmestic Pins 550 series

2 Pages

-

Installation Technology

8 Pages

-

SPIROL Precision Shims

8 Pages

-

Medical Device Applications

2 Pages

-

SPIROL Solid Pins Catalog

12 Pages

-

Series 2000 Series 2000

4 Pages

-

Aerospace Applications Flyer

2 Pages

-

PH series PH series

2 Pages

-

HC series HC series

2 Pages

-

Tables Standard

2 Pages

-

Tables Lift and Roll

2 Pages

-

SPD, CXA, CXD, CXE CRD

2 Pages

-

880 Series

2 Pages