Catalog excerpts

Local regulations may restrict the use of this product to below the conditions quoted. In the interests of development and improvement of the product, we reserve the right to change the specification without notice. © Copyright 2017 spirax ysarco FV Flash Vessel Description The Spirax Sarco FV flash vessel is designed and constructed to ASME VIII DIV 1 2004 + ADD06. The design is free-draining which is essential in boiler blowdown applications. Applications These vessels are particularly suited to boiler blowdown heat recovery systems where efficient separation of the flash steam from the blowdown is essential to prevent contamination of the boiler feedtank and / or heat transfer surfaces. Spirax Sarco flash vessels are equally suited to condensate flash steam applications. Principal features: - Designed and constructed in compliance with the European Pressure Equipment Regulations 2014/68/EU. - Low separation velocity to produce drier steam. - Free-draining. Sizes and pipe connections Connections available as standard: Screwed connections to BS 21 taper. Flanged connections to EN 1092 PN16. Note: Vessels are available flanged to ASME B16.5 Class 150 or 300, or screwed NPT. Limiting conditions Maximum design conditions (body) are 14 bar g @ 198 °C (saturation temperature of steam). Minimum design (operating) temperature -10 °C Cold hydraulic test pressure in accordance with European Pressure Equipment Directive 2014/68/EU. Note : Maximum design Pressure and Temperature can be further limited, lower than that stated on the nameplate depending on the chosen flange rating of the system. PN16 13.3 bar g @ 198 °C Note: These vessels will withstand full vacuum conditions. First for Steam Solutions

Open the catalog to page 1

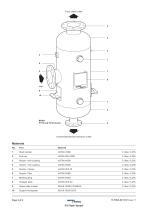

Flash steam outlet Condensate/residual blowdown outlet MaterialsNo. Part Material 1 Shell cylinder 3 Nozzle - Half coupling 4 Nozzle - Full coupling spirax Tsarco TI-P404-03 EMM Issue 11

Open the catalog to page 2

Use the chart below to select the appropriate flash vessel. It is necessary to know the pressure on the steam traps or boiler pressure in the case of blowdown heat recovery, the flash steam pressure (desired or existing), and the condensate or blowdown flowrate. Example 1: (solid lines) A boiler plant operating at 12 bar g has a TDS control blowdown flowrate of 2 500 kg/h (3 boilers at 833 kg/h each). The flash steam from the blowdown is to be added to the low pressure steam system operating at 1 bar g. 1. From boiler pressure move horizontally to flash steam pressure - A 2. Drop vertically...

Open the catalog to page 3

Installation The vessel should be mounted with the flash steam outlet at the top, and connected as indicated below. Each vessel incorporates a " screwed boss for a pressure gauge. For drainage, it is recommended that a float trap is fitted. A safety valve connection is provided on the vessel. It should not be assumed that the safety valve will be the same size as the connection. Safety valve sizing and selection should be in accordance with National and Local Regulations. Flash steam outlet How to order Example: 1 off Spirax Sarco FV6 flash vessel having screwed BSP connections. The unit is...

Open the catalog to page 4All Spirax Sarco catalogs and technical brochures

-

Safety valves overview

12 Pages

-

Exhaust Vapour Condenser

2 Pages

-

BBV Bottom Blowdown Valve

2 Pages

-

Condensate recovery solutions

16 Pages

-

TN2000

1 Pages

-

VHT Vent Heads

1 Pages

-

SC20 Sample Coolers

3 Pages

-

Boiler feedback systems

8 Pages

-

Steam Trapping Overview

22 Pages

-

BDV60 Blowdown vessels

7 Pages

-

VHT vent heads

2 Pages

-

STAPS Sales Brochure

10 Pages

-

M850 Flow Computer

6 Pages

-

Spirax Sarco the products

24 Pages