Catalog excerpts

Local regulations may restrict the use of this product to below the conditions quoted. In the interests of development and improvement of the product, we reserve the right to change the specification without notice. © Copyright 2020 BDV60 Blowdown Vessels Description BDV60 blowdown vessels are marked and comply with the Pressure Equipment Directive (PED). They also comply with Blowdown Systems, Guidance for Industrial Steam Boilers (Ref: BG03), for the construction of vessels used in boiler blowdown applications, issued by the Health and Safety Executive. BDV60 blowdown vessels are designed to accept discharges from: Manual/automatically controlled bottom blowdown. Automatic TDS blowdown control valves and systems. Controlled bleed valves for continuous blowdown. Level control chambers and level gauge glasses. Heat recovery equipment. Design and construction Design code Carbon steel Standard EN 1092 ASME Class 150 and ASME Class 300 flanges Paint finish Temperature resistant silver paint Associated equipment - VH vent head - Pressure gauge and 'U' syphon Vessel drain valve Cooling water system For further details please refer to the appropriate literature.

Open the catalog to page 1

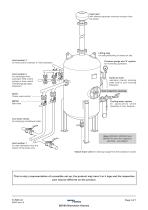

Shell cylinder Dished ends Wrapper plate Nozzle, pipe Support leg/foot Nozzle, flange Nameplate stand-off Nozzle, coupling Nameplate bracket Inspection opening Inspection opening gasket Rubber, NR/SBR Impingement plate Long radius butt weld elbow (Internal)

Open the catalog to page 2

Vent head with internal separator removes moisture from the steam. Lifting lugs for safe positioning of vessel on site. Inlet number 3 for level control chamber or TDS blowdown. Pressure gauge and 'U' syphon for monitoring operation. Inlet number 2 for discharges from automatic TDS control system or level control chamber/gauge glass blowdown. Outlet to drain maintains internal standing water level to cool incoming blowdown. Oval inspection opening DCV2 Check valve control M21S2 Ball valve Cooling water system for applications where blowdown is very frequent. Line drain valves for emptying a...

Open the catalog to page 3

The selection of a blowdown vessel depends on the flowrate and the proportion of flash steam released. The following factors affect the selection: The blowdown line size. The length of blowdown line between the boiler and the blowdown vessel. For example the sizing below assumes the blowdown line has an 'equivalent straight length' of at least 7 m. When estimating 'equivalent straight length' the lengths shown in Table 1 should be added to the length of straight pipe to allow for valves and fittings. From Table 1 it will be seen that in most practical applications it would be unusual for...

Open the catalog to page 4

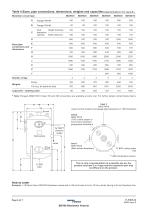

Table 1 Equivalent straight lengths Blowdown line size Pipe fitting or valve Table 3 Vent head selection Equivalent length in metres Note: The vent head required depends on the vessel selected For a BDV60/3 select a VH4 vent head For a BDV60/4 select a VH4 vent head Long radius bend For a BDV60/5 select a VH6 vent head Manifold inlet For a BDV60/6 select a VH6 vent head Globe valve For a BDV60/8 select a VH8 vent head Check valve For a BDV60/10 select a VH8 vent head Blowdown valve Graph 1 Blowdown flowrates Table 2 Blowdown vessel selection Blowdown line size This graph will give the...

Open the catalog to page 5

Table 4 Sizes, pipe connections, dimensions, weights and capacities (approximate) in mm, kg and L Blowdown vessel type Oval Height (Internal) Inspection opening Width (Internal) Sizes,pipe connections and dimensions Full (e.g. for hydraulic test) Number of legs Weights Capacities - standing water Note: Flanged ASME B16.5 Class 150 and 300 connections are available at extra cost. For further details contact Spirax Sarco. Inlet 3 DN25 PN16 (Level control chamber and gauge glass blowdown or TDS blowdown) Inlet 2 DN25 PN16 (TDS control system or level control chamber/ gauge glass blowdown) G F...

Open the catalog to page 6

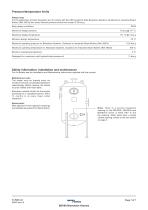

Pressure/temperature limits Please note: For the application of boiler blowdown and to comply with the HSE Guidance Note Blowdown Systems, Guidance for Industrial Steam Boilers (Ref: BG03) the vessel internal pressure should not exceed 0.35 bar g. Body design conditions Maximum design pressure Maximum design temperature Minimum design temperature Maximum operating pressure re. Blowdown Systems, Guidance or Industrial Steam Boilers (Ref: BG03) Maximum operating temperature re. Blowdown Systems, Guidance for Industrial Steam Boilers (Ref: BG03) Minimum operating temperature Designed for a...

Open the catalog to page 7All Spirax Sarco catalogs and technical brochures

-

Safety valves overview

12 Pages

-

Exhaust Vapour Condenser

2 Pages

-

BBV Bottom Blowdown Valve

2 Pages

-

Condensate recovery solutions

16 Pages

-

TN2000

1 Pages

-

VHT Vent Heads

1 Pages

-

SC20 Sample Coolers

3 Pages

-

Flash Vessel

4 Pages

-

Boiler feedback systems

8 Pages

-

Steam Trapping Overview

22 Pages

-

VHT vent heads

2 Pages

-

STAPS Sales Brochure

10 Pages

-

M850 Flow Computer

6 Pages

-

Spirax Sarco the products

24 Pages