Catalog excerpts

www.spantechllc.com . SpanTech has developed a new concept in plastic chains. MicroSpan > ή chain was developed for the companysPowered Transfer program. Powered Transfers are devices that fill the space between the end of one con- veyor and the next. They are used when ғend to end product movement is required and conventional chutes or idler rollers will not work. To learn more about SpanTechԒs Powered Transfer program, visit our website at > MicroSpan > ή chain is made of acetal plastic, and has a charcoal grey color. It is a very small, all-metricdesign available in 4mm (0.16) and 6mm...

Open the catalog to page 3

? 4mm Raised High Friction MicroSpan > ( below ). This chain is 4mm (0.16Δ) thick and has raisedpoints on its surface. It is used on inclines where the product surface is soft and the points can aid in gripping the product. Note the open rod segments in the photo ( below ); the drive sprocket teethinterface with and drive the chain at this point. This open feature allows more debris to pass through the chain. > FLOW ? 6mm Raised High Friction MicroSpan > ( below ). Used in applications where a stronger chain isrequired; 6mm chain is more than twice as strong as 4mm chain. > FLOW revised...

Open the catalog to page 4

MicroSpan > chain is designed to run on a small Nose Bar. The Bar thickness is 6mm (0.24Δ) with a 3mm(0.12) radius on the end. The Nose Bar ( > 6mm Nose Bar4mm Chain 14mm(0.55Ԕ) 6mm Nose Bar6mm Chain 18mm(0.71) 6mm (0.24Ԕ) above ) has been developed by SpanTech to withstand the high wear and heat generated bythe application. The Nose Bar is made of extruded #6063 aircraft grade aluminum. The extrusion is drilled and countersunk, then hard plated with a nickel alloy. This nickel plating can withstand high pressure washdown applications. > revised 02-05 2005 SpanTech LLC 5 size="-3">

Open the catalog to page 5

MicroSpan > chain has a snap fit design. One side of the link has a hook; the other side has a pin ( below ).There is no independent rod. The chain elements are molded in two lengths: 60mm (2.36Δ) and 120mm (4.72). The width module( > 15mm(0.59Ԕ) above ) is 15mm (0.59).The chain is assembled in a ԓbrickwork pattern. The standard width for MicroSpan > Ԯ stock is 300mm(11.81); a standard roll is 15.24m (50 ft.) in length. > MicroSpan > Ԯ chain stock is 300mm (11.81) wide, and is cut to width on a conventional table saw. SpanTech uses a special blade, but conventional carbide-tipped wood...

Open the catalog to page 7

M > ICRO S > PAN S > PROCKET M > OUNTING S > PECIFICATIONS Sprocket Locations on Shaft Chain Widths Exceeding 300mm [ ] 0.0 POSITION 1α0.01 [Ա0.25mm] POSITION 2 0.01є [0.25mm] POSITION 3ѱ0.01 [Ա0.25mm] 0.545+0.100Ԕ 13.84mm +2.54mm -0.000 -0.00mm O 0.161Ԕ [4.09mm] (#20 DRILL)ALL HOLES MUST BE ALIGNED AND PERPENDICULAR TO SHAFT AXIS 300mm 2mm MINIMUM SPACINGBETWEEN CHAINS revised 02-05 2005 SpanTech LLC 11 size="-3">

Open the catalog to page 11

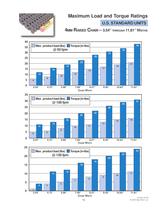

MicroSpan > TransferStandard Configuration > MicroSpan ή Chain Back bend limit is31.75mm (1.25) All torque values provided on the following pages are based upon a MicroSpan > Ӯ Transfer having astandard chain path configuration (above). The stated values reflect the maximum operational torque. Any variations or modifications of the standard configuration will alter the actual torque values.Consult SpanTech for information regarding applications greater than 300mm (11.81) in width. > revised 02-05ԩ 2005 SpanTech LLC 12 size="-2">

Open the catalog to page 12

IDTH revised 02-05ԩ 2005 SpanTech LLC

Open the catalog to page 13

90 MMTHROUGH 300 MM W IDTHS 1 2 > Max. product load (kg) 1 > @ 15 m/min (50 fpm) 3.14.55.46.37.78.69.510.8 1.61.92.42.93.43.74.34.7 02 4 6 8 > 0 12841062 90mm120mm150mm180mm210mm240mm270mm300mm C HAIN W IDTH Max. product load (kg) @ 30 m/min (100 fpm) 1.82.23.13.64.55.05.46.3 1.21.41.61.92.22.52.83.1 01 2 3 4 5 6 7 8 > 0 86475321 90mm120mm150mm180mm210mm240mm270mm300mm C HAIN W IDTH Max. product load (kg) Torque (N-m) Torque (N-m) Torque (N-m) @ 45 m/min (150 fpm) 1.31.82.22.73.13.64.14.5 0.91.11.41.61.82.02.22.4 01 2 3 4 5 > 0 45321 90mm120mm150mm180mm210mm240mm270mm300mm C HAIN W IDTH...

Open the catalog to page 14

IDTH revised 02-05ԩ 2005 SpanTech LLC

Open the catalog to page 15

IDTH revised 02-05֩ 2005 SpanTech LLC >

Open the catalog to page 16

MicroSpan Test Conveyor ALUES > The Maximum Load data for 6mm Raised Chain, provided on the following pages, is based on the actual performance of a MicroSpan ή test conveyor that is 2.29m (7.5 ft.) in length (above). Theconveyor has a center drive and standard plated aluminum nose bars on each end. A dead load is applied to the midpoint of the unit; the load is held in accumulation. Torque is measured with a dynamometer. The Maximum Load values shown in the charts are based on 40 percent of the failure point. The center drive has standard 44-tooth sprockets on standard spacing. The chain...

Open the catalog to page 17

IDTH revised 02-05ԩ 2005 SpanTech LLC

Open the catalog to page 18

90 MMTHROUGH 300 MM W IDTHS 2 5 > Max. product load (kg) 2 > @ 15 m/min (50 fpm) 1 5 1 > 7.210.012.215.017.220.022.224.5 6.27.89.811.613.615.017.218.8 0 5 > 0 251520105 90mm120mm150mm180mm210mm240mm270mm300mm C HAIN W IDTH 2 5 > Max. product load (kg) 2 > @ 30 m/min (100 fpm) 1 5 1 > 6.89.010.913.115.417.720.022.2 5.47.08.810.412.213.815.617.0 05 > 0 251520105 90mm120mm150mm180mm210mm240mm270mm300mm C HAIN W IDTH 2 > Max. product load (kg) Torque (N-m) Torque (N-m) Torque (N-m) @ 45 m/min (150 fpm) 1 5 1 > 5.47.29.010.912.714.516.318.1 4.66.07.28.810.211.412.814.2 05 > 0 2010155...

Open the catalog to page 19All SpanTech catalogs and technical brochures

-

EZSpan Belt Conveyor

2 Pages

-

Wedge Unit Brochure

2 Pages

-

Twist Brochure

2 Pages

-

Transpositor Brochure

2 Pages

-

Traffic Cop Brochure

2 Pages

-

Outrunner Spiral Brochure

2 Pages

-

MicroSpan Transfer

2 Pages

-

High Speed Switch Brochure

2 Pages

-

Helical Curve Brochure

2 Pages

-

Span Tech Brochure

17 Pages

-

MC300HD Conveyor

8 Pages

-

Product Overview

12 Pages

-

High-Speed Switch

1 Pages

-

J-Trax

1 Pages

-

Topper Lift

1 Pages

-

Powered Roller Transfer

1 Pages

-

spiral chain conveyor

10 Pages

-

wedge conveyor

20 Pages

-

MiniLink

1 Pages

-

spiral conveyor

1 Pages

-

CV Series Curving Conveyor

12 Pages

-

incline or Decline Conveyor

20 Pages

-

ST Series Straight Conveyor

16 Pages