Catalog excerpts

ACTUATORS FEATURES • Single Piece, Dual Nodal Mount Horn and Booster Stack • Compact System Profile • High Force Frictionless Cam/Bearing Actuation • Pivoting Lift and Carry Bar for Ergonomic Ease in Handling • Fixed Trigger Handle with Low Force Trigger Switch • 90° Keyed Tips and Anvils Provide 4 Weld Surfaces • Charged Tubes are Crimped, Welded and Cut in less than 2 Seconds • Explosion-proof Version Available Sonics’ 20 kHz ultrasonic tube sealing systems consist of the actuator shown above and a power supply, the MX or MSC series, as shown below. Sonics’ 20 kHz power supplies are available in 2 versions, the MX Series, with standard keypad operation and the SmartControl (MSC) Series with full color touch screen controls. The features of the models are compared below. MODELS POWER LEVELS MXT Time Based Weld Mode • 1500 Watts Peak Power MXE Time and Energy Based Weld Modes • 2500 Watts Peak Power MSC SmartControl with Time, Energy • 4000 Watts Peak Power and Height-Based Weld Modes

Open the catalog to page 1

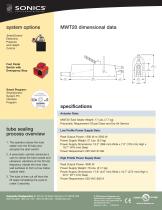

system options SmartControl Electronic Pressure and Height Control Foot Pedal Switch with Emergency Stop Smart Program: SmartControl System PC Interface Program 1969 – 2011 Sonics & Materials, Inc. SmartControl Power Supply Program specifications Actuator Data: MWT20 Tube Sealer Weight: 17 Lbs. (7.7 kg) Pneumatic Requirement: 60 psi Clean and Dry Air Service tube sealing process overview 1. The operator places the tube sealer over the fill tube and actuates the start switch. 2. A pneumatic cylinder advances a cam to clamp the tube closed and ultrasonic vibrations at the 20 kHz frequency...

Open the catalog to page 2All Sonics + Materials catalogs and technical brochures

-

Plastics Assembly

8 Pages

-

ULTRASONIC LIQUID PROCESSORS

31 Pages

-

Tube Sealers

2 Pages

-

Sonochemistry Equipment

1 Pages

-

Flow Cells & Cup Horn

1 Pages

-

Multi-Element Probes

1 Pages

-

Microtips & Extenders

1 Pages

-

Probes and Boosters

2 Pages

-

Atomizers

3 Pages

-

VCX 1500 HV (1500 watts)

1 Pages

-

VCX 1500 (1500 watts)

1 Pages

-

VCX130PB (130 watts)

1 Pages

-

VCX130 (130 watts)

1 Pages

-

Hot Plate Welders

2 Pages

-

Vibration Welders

4 Pages

-

Food Cutting

2 Pages

-

Hand Held Welders

2 Pages

-

e-Press

2 Pages

-

40 kHz Ultrasonic Welder

2 Pages

Archived catalogs

-

POWER SUPPLIES

1 Pages

-

Power Supplies_2008

2 Pages