Catalog excerpts

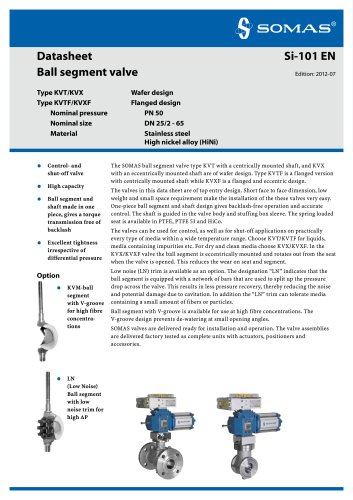

Datasheet Ball segment valve Type KVTW-A/KVXW-A Nominal pressure Nominal size • Control and shut-off valve • High capacity • One-piece shaft gives torque transmission free of backlash • Excellent tightness irrespective of differential pressure • Easy maintenance Wafer design Standard face to face dimension PN 40/25/20/16/10 PN 25/20/16/10 PN 20/16/10 DN 25 - 65 DN 80 - 100 DN 150 - 250 The SOMAS ball segment valve type KVTW with a centrically mounted shaft, and KVXW with an eccentrically mounted shaft are of wafer design. The valve called the A-version is manufactured in standard face to face dimensions common in certain markets. The valve is also manufactured in D-type version with a short face to face dimension. The valve body is in one piece. Shaft device is also in one piece for torque transmission free of backlash. The spring-loaded seat is available in three alternative materials (PTFE, PTFE 53 and HiCo [High Cobalt Alloy]). The valves can be used for control, as well as for shut-off applications on practically every type of media within a wide temperature range. Choose KVTW for liquids, media containing impurities etc. For dry and clean media choose KVXW. In the KVXW-valve the ball segment is eccentrically mounted and rotates out from the seat when the valve is opened. This reduces the wear on seat and segment. Low noise trim is available as an option on DN50 to DN250. The designation “LN” indicates that the ball segment is equipped with a network of bars that are used to split up the pressure drop across the valve. This results in less pressure recovery, thereby reducing the noise and potential damage due to cavitation. Note! Capacity factors will be reduced for valves with LN-trim. Ball segment DN50 to DN250 with V-groove is available for use at high fiber concentrations. The V-groove design prevents dewatering at small opening angles. The SOMAS valves are delivered ready for installation and operation. The valve assemblies are delivered factory tested as complete units with actuators, positioners and accessories.

Open the catalog to page 1

Tightness class The tightness class is related to the chosen material in the seat ring. PTFE seat Code A EN 60534-4 VI (ASME B16-104 Class VI). PTFE 53 seat1 Code B EN 60534-4 VI (ASME B16-104 Class VI). HiCo seat Code T EN 60534-4 IV alt. V (ASME B16-104 Class IV alt. V). 1 50% PTFE + 50% 1.4435 (316L) powder (percentage by weight). FLP1 = One dimension bigger pipe size FLP2 = Two dimensions bigger pipe size FLP3 = Three dimensions bigger pipe size Liquid pressure recovery factor FL Flow characteristics 100% Flow Pipe geometry factor FP Valve Pressure and temperature rating According to...

Open the catalog to page 2

Capacity factor Kv and Resistance factor ξ for ball segment valve type KVTW/KVXW Metric DN 25 40 50 65 80 100 150 200 250 Capacity factor Cv and Resistance factor ξ for ball segment valve type KVTW/KVXW US NPS 1 1.5 1,5 2 2.5 2,5 3 4 6 8 10

Open the catalog to page 3

Metric Ball segment valve type KVTW -A (standard) A Wafer design

Open the catalog to page 4

Actuator selection table Manual override Face to face dimension Further technical information According to Industrial branch standards, standard face to face dimension. Technical data for the materials used in the SOMAS valves, flange standard, steam data, etc. can be found in section 6 of the SOMAS catalogue. Flange standard SOMAS ball segment valves type KVTW DN25/2–250 and KVXW with nominal size DN25–250 are flangeless and should be clamped between flanges. When ordering, please always state the pressure rating of the counter flanges. See the valve specification system on page 8, code...

Open the catalog to page 7

Within the process industry and the energy sector there are a number of applications where process data in combination with standard control valves will end up with problems such as high noise level and erosion. These problems are mostly related to cavitations and high flow velocities inside the valve. State desired valve according to the valve specification system below as well as type of actuator, positioner and accessories. Valve sizing Use SOMAS valve sizing program SOMSIZE to find the correct valve size. All sizing factors are included in the program. Note! By using a standard ball...

Open the catalog to page 8All SOMAS catalogs and technical brochures

-

Si-208 EN

12 Pages

-

Ball segment valve

8 Pages

-

Actuators Type A

8 Pages

-

Check valves: BCV/BCVA

4 Pages

-

Ball valves: SKV

12 Pages

-

Si-210

4 Pages

-

Si-206

8 Pages

-

Si-205

8 Pages

-

Si-204

8 Pages

-

Si-203

8 Pages

-

Si-113

8 Pages

-

Si-112

8 Pages

-

Si-101

8 Pages

-

Hand lever - Gear unit

4 Pages

-

3-piece full bore ball valve

4 Pages

-

Butterfly valves: VSS

8 Pages

-

KVTW-D/KVXW-D

8 Pages

-

KVTF-C/KVXF-C

8 Pages

-

Si-111 EN

4 Pages

-

Si-110 EN

8 Pages

-

Si-109 EN

8 Pages

-

Si-108 EN

4 Pages

-

Si-105 EN

4 Pages

-

Si-103 EN

4 Pages

-

Valve Positioner

13 Pages

-

Manual actuators

2 Pages

-

Pneumatic actuator

8 Pages

-

CHECK VALVE

4 Pages

-

Butterfl y valve

8 Pages

-

Ball segment valve

8 Pages