Catalog excerpts

Datasheet Butterfly valve for exhaust gas applications Type VSS Wafer design Nominal pressure PN 10 - 25 Nominal size DN 80 - 800 Material Stainless steel triple • Advanceddesign eccentric • Designed for control and shut-off applications • Standard up to applications 600° C (1112 °F). For higher temperatures consult SOMAS • Tightness class inEN accordance with 60534-4 Class V as standard • Wafer design (Mounted between flanges) alt. lugged design SOMAS butterfly valves, type VSS is used as a control, on/off and shut-off valve. The VSS valve is designed to handle a wide range of of gases within a broad temperature range. The valves have an advanced triple eccentric design including a unique shape of the disc allows the use of a solid stainless steel seat. The solid seat remains un-affected by high flow velocities and temperatures. A good valve function is achieved also in difficult applications. The seat is easily replaceable. The VSS valve can be mounted between flanges and is also supplied in lugged design. The SOMAS valves are delivered ready for installation and operation. The valve assemblies are delivered factory tested as complete units with actuators, positioners and acc

Open the catalog to page 1

Temperature performance The VSS is designed to operate at very high temperature and still maintain tight shutoff over a long period of time. The standard material combination for VSS exhaust gas valve is based on 1.4408 material for applications up to 550°C. Temp PN 25 PN 25 Tightness class Pipe geometry factor FP The tightness class dependent on application to the chosen material in the seat ring. Metal seat Code D EN 60534-4 V (ASME B16-104 Class V). Flow characteristics Valve opening Liquid pressure recovery factor FL Opening angle Factor Flp Factor Flp is valid for all sizes

Open the catalog to page 2

Standard disc - Capacity factor Kv and Resistance factor ξ Slim disc - Capacity factor Kv and Resistance factor ξ Opening angle DN 600 650 700 800 Disc Slim Slim Slim Slim Max. allowable pressure drops/torque figures Maximum allowable pressure drops are valid at 20° C (see below). Max. pressure drop. bar at opening angle

Open the catalog to page 3

VSS Butterfly valve with single acting (spring loaded) actuators DN

Open the catalog to page 5

Manual operation

Open the catalog to page 6

Flange standard Further technical information SOMAS butterfly valve type VSS in this data sheet is of wafer type for mounting between flanges PN 10-25. Technical data for the materials used in the SOMAS valves, flange standard, steam data, etc. can be found in section 6 of the SOMAS catalogue. For other standards consult SOMAS. The valve can also be delivered in lugged design. The valve can be ordered in other flange standards. The valves can be fitted with SOMAS manual, on/off or control actuators in accordance with the selection table. The valves will then be delivered as tested units...

Open the catalog to page 7

The standard VSS valve is designed to be mounted between flanges, but is also available in lugged design. State desired valve according to the valve specification system below as well as type of actuator, positioner and accessories. Face to face dimension Valves face to face dimension according to EN 558-1 Series 20. Valve specification system VSS Butterfly valve advanced type Bearing – valve body/shaft 2 Valve body design 9 A = Wafer design according to EN 558-1. Series 20 6 Material – seat X = Graphite with Seal air connection 5 = PN 25 7 Material – shaft 4 Material – valve body X =...

Open the catalog to page 8All SOMAS catalogs and technical brochures

-

Si-208 EN

12 Pages

-

Ball segment valve

8 Pages

-

Actuators Type A

8 Pages

-

Check valves: BCV/BCVA

4 Pages

-

Ball valves: SKV

12 Pages

-

Si-210

4 Pages

-

Si-206

8 Pages

-

Si-205

8 Pages

-

Si-204

8 Pages

-

Si-203

8 Pages

-

Si-113

8 Pages

-

Si-112

8 Pages

-

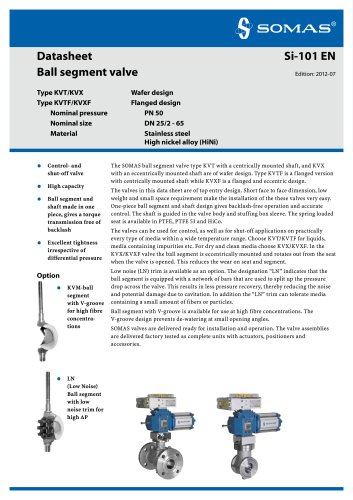

Si-101

8 Pages

-

Hand lever - Gear unit

4 Pages

-

3-piece full bore ball valve

4 Pages

-

Butterfly valves: VSS

8 Pages

-

KVTW-D/KVXW-D

8 Pages

-

KVTW-A/KVXW-A

8 Pages

-

KVTF-C/KVXF-C

8 Pages

-

Si-111 EN

4 Pages

-

Si-110 EN

8 Pages

-

Si-109 EN

8 Pages

-

Si-108 EN

4 Pages

-

Si-105 EN

4 Pages

-

Si-103 EN

4 Pages

-

Valve Positioner

13 Pages

-

Manual actuators

2 Pages

-

Pneumatic actuator

8 Pages

-

CHECK VALVE

4 Pages

-

Butterfl y valve

8 Pages

-

Ball segment valve

8 Pages