Catalog excerpts

WHITE ELECTRONIC DESIGNS CORPORATION Illuminating enhanced flat-panel display design with SolidWorks Premium Enhanced design visualization is one of the reasons why WEDC has been able to decrease its product design cycles by 35 percent with SolidWorks software. The Display Systems Division (DSD) of White Electronic Designs Corporation (WEDC) is a leading manufacturer of flat-panel LCD displays for use in specialized applications that require custom enhancements. Bright sunshine, excessive movement, and constant vibration are examples of the harsh conditions under which WEDC displays must reliably function. The different types of custom display requirements that have surfaced in recent years created the need for greater productivity, agility, and flexibility in DSD’s product development group, in order to capitalize on emerging opportunities. These needs prompted DSD to reassess its CAD tools—Autodesk Inventor® and CADKEY®—in late 2003, according to Andrew Robinson, associate mechanical engineer. “We believed that using Inventor and CADKEY software was holding us back in some respects,” Robinson explains. “We had both systems because of the merger, and realized that we were doing a lot of remodeling as a result of going back and forth between the two platforms. We were also experiencing difficulties in communicating with vendors, because we had to deal with a large number of file conversions and IGES translations. We were looking for a single system that was easier to use, more capable, and better suited to meeting our needs and goals.” DSD evaluated Pro/ENGINEER® and SolidWorks® 3D CAD software before selecting the SolidWorks Premium suite of product development software. The company chose SolidWorks software because of its ease of use, integrated SolidWorks product data management (PDM) software, advanced visualization capabilities, sheet-metal design tools, and additional integrated applications. “We found out about SolidWorks software from one of our sheet-metal vendors,” Robinson recalls. “When we saw the section-view capabilities, we knew SolidWorks software was the right solution. With flat-panel displays, all the elements rest closely together in a very tight space. The ability to look inside using section views is so much more efficient than estimating how parts align.” Results: • Shortened design cycles by 35 percent • Improved management of product design data • Eliminated need to redraw models • Enhanced design communications

Open the catalog to page 1

Enhanced visualization compresses design cycles “THE ABILITY TO LOOK INSIDE Since implementing SolidWorks Premium in early 2004, DSD engineers have used the software for design modifications and new product design. Robinson says that by using SolidWorks software on the design of a new industrial-type monitor for use in factory settings, he was able to meet an ambitious seven-week design deadline, cutting the design cycle by 35 percent. The product, which carries the code name “Arago,” was the first product that DSD developed completely in SolidWorks software. USING SECTION VIEWS IS SO MUCH...

Open the catalog to page 2All SOLIDWORKS catalogs and technical brochures

-

SOLIDWORKS VISUALIZE

6 Pages

-

SOLIDWORKS SIMULATION SUITE

4 Pages

-

SOLIDWORKS Solutions

6 Pages

-

SOLIDWORKS PDM

2 Pages

-

SOLIDWORKS Premium_2016

6 Pages

-

SOLIDWORKS Composer

2 Pages

-

SolidWorks Plastics

2 Pages

-

SOLIDWORKS ENTERPRISE PDM

4 Pages

-

3D COMPONENT DESIGNER

2 Pages

-

INDUSTRY INNOVATION

3 Pages

-

3D SCULPTOR

2 Pages

-

SOLIDWORKS ELECTRICAL SUITE

6 Pages

-

SOLIDWORKS MBD

4 Pages

-

3DVIA COMPOSER

4 Pages

-

SW_Plastics_DS_2013

4 Pages

Archived catalogs

-

PROJECT PLANNER

2 Pages

-

Business Innovation

6 Pages

-

2017 SWK PDM

4 Pages

-

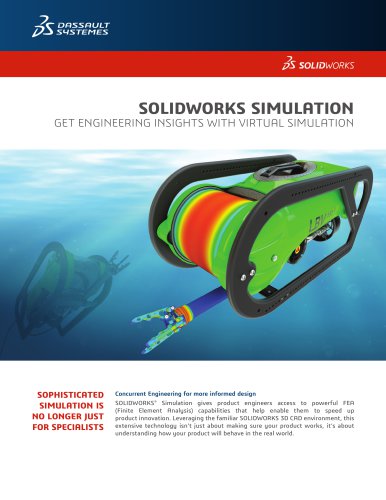

SOLIDWORKS Simulation_2016

6 Pages

-

SOLIDWORKS Subscription

2 Pages

-

SOLIDWORKS PREMIUM_2015

6 Pages

-

SOLIDWORKS Simulation Suite

4 Pages

-

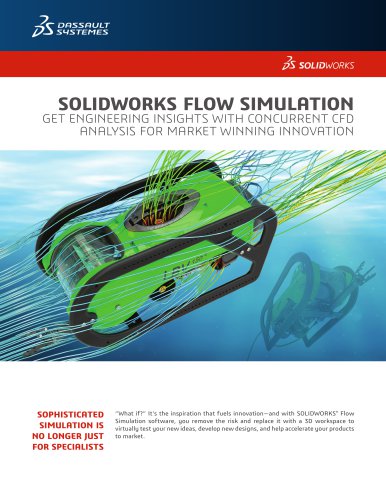

SOLIDWORKS Flow Simulation

4 Pages

-

SOLIDWORKS CircuitWorks

4 Pages

-

SOLIDWORKS EPDM

4 Pages

-

SolidWorks Simulation_2014

6 Pages

-

DRAFTSIGHT

2 Pages

-

SW2014 Datasheet EPDM

4 Pages

-

SW2014 Datasheet Top Ten

2 Pages

-

SolidWorks Premium_2013

8 Pages

-

SOLIDWORKS SIMULATION 2010

6 Pages

-

EPDM

4 Pages

-

hcv

2 Pages

-

em

2 Pages

-

SW_Electrical_DS_2013

4 Pages

-

SOLIDWORKS PREMIUM 2011

4 Pages

-

SolidWorks Routing

2 Pages

-

PhotoWorks Product Overview

2 Pages

-

COSMOSWorks Designer

2 Pages

-

SolidWorks 2008

2 Pages