Catalog excerpts

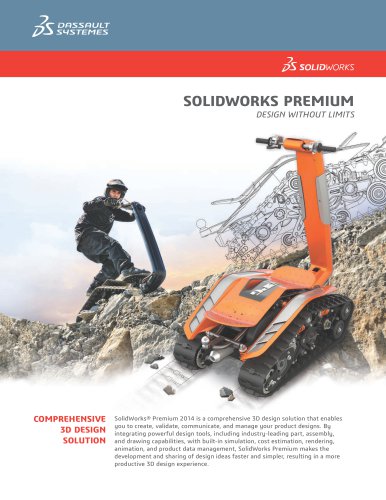

SOLIDWORKS PLASTICS Optimize the design of plastic parts and injection molds OPTIMIZE PART DESIGNS ELIMINATE SINK MARKS MINIMIZE COMMON INJECTION MOLDING DEFECTS Plastic Cordless Drill Housing | Designed in SolidWorks SIMULATION-DRIVEN DESIGN FOR PLASTICS PART PRODUCTION u I F Y V ER SolidWorks Plastics brings injection molding simulation directly to designers of plastic SolidWorks Plastics makes it easy for parts and injection molds. You don’t have to be an expert to easily identify and address companies that design plastic parts or potential defects by making changes to the part or mold design, plastics material, or injection molds to predict and avoid processing parameters, saving resources, time, and money. manufacturing defects during the earliest ® M A N U FACT U R A BIL ITY stages of design, eliminating costly rework, INTUITIVE WORKFLOW AND DESIGN ADVICE improving quality, and accelerating time-tomarket. Fully integrated with SolidWorks CAD, SolidWorks Plastics works directly on your 3D model, avoiding translation issues. You see this intuitive software helps part designers, the impact of design changes right away. Powerful and fast state-of-the-art meshing covers mold designers, and mold makers optimize geometries from thin-walled parts to very thick and solid parts. designs for manufacturability without leaving An intuitive interface leads you step by step. Guided analysis, intelligent defaults, and automated processes ensure correct setup, even if you rarely use simulation tools. The SolidWorks Plastics material database contains thousands of commercial plastics and is fully customizable. their familiar 3D design experience.

Open the catalog to page 1

Part designers get rapid feedback on how modifications to wall thickness, gate locations, materials, or geometry can affect the manufacturing of their part, while mold designers can quickly optimize multi-cavity and family mold layouts and feed systems—including sprues, runners, and gates. ANALYZE AND OPTIMIZE A RANGE OF GEOMETRIES INCLUDING THIN-WALLED PLASTIC PARTS. . . Y PARTS AND CHUNK . . . OR THICK NATURE SOLID IN THAT ARE The Results Adviser provides practical design advice and troubleshooting tips to help diagnose and solve potential problems. This powerful information gives users...

Open the catalog to page 2

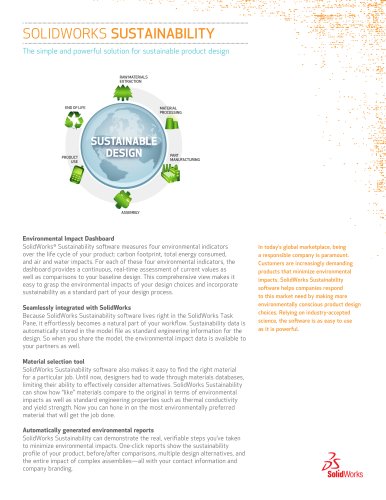

GE COST OF CHAN THE COST OF CHANGE impact of change cost of change While the cost of making changes is low in the early stages of product development, the impact is highest. The sooner you can optimize your plastic parts and injection molds for manufacturability, the better. Design changes in the early stages of product development cost less and have the greatest impact on improving manufacturability. The cost of change increases substantially further downstream and can lead to significant time-to-market delays. Part Design Mold Design Mold Manufacture Part Production Product Launch The...

Open the catalog to page 3

Unbalanced filling in family molds (as seen here) can be predicted and avoided with SolidWorks Plastics. ANCE AUTOMATICALLY BAL SYSTEMS OF THE RUNNER ID FAMILY MOLDS AND AVO G PROBLEMS MANUFACTURIN Plastic Electronics Housing | hondaDesign, LLC FOR MOLD DESIGNERS AND MOLD MAKERS SolidWorks Plastics Premium u EM SYST SolidWorks Plastics Premium gives designers or builders of injection molds an • Windows 7 (32- or 64-bit) or Windows Vista® accurate, easy-to-use way to optimize them. Quickly create and analyze single, • 2 GB RAM (minimum) multi-cavity, and family mold layouts. • Avoid costly...

Open the catalog to page 4All SOLIDWORKS catalogs and technical brochures

-

SOLIDWORKS VISUALIZE

6 Pages

-

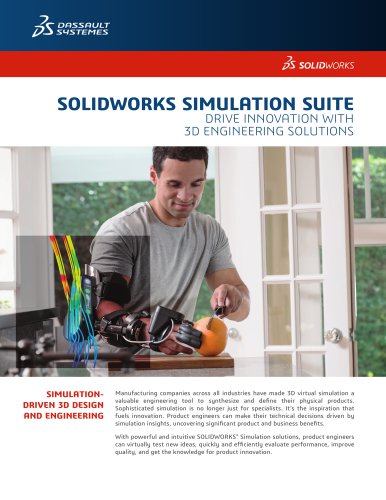

SOLIDWORKS SIMULATION SUITE

4 Pages

-

SOLIDWORKS Solutions

6 Pages

-

SOLIDWORKS PDM

2 Pages

-

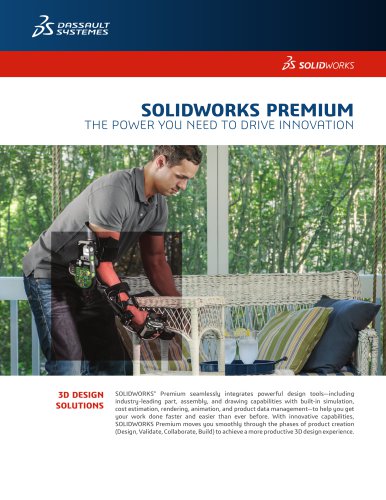

SOLIDWORKS Premium_2016

6 Pages

-

SOLIDWORKS Composer

2 Pages

-

SolidWorks Plastics

2 Pages

-

SOLIDWORKS ENTERPRISE PDM

4 Pages

-

3D COMPONENT DESIGNER

2 Pages

-

INDUSTRY INNOVATION

3 Pages

-

3D SCULPTOR

2 Pages

-

SOLIDWORKS ELECTRICAL SUITE

6 Pages

-

SOLIDWORKS MBD

4 Pages

-

3DVIA COMPOSER

4 Pages

Archived catalogs

-

PROJECT PLANNER

2 Pages

-

Business Innovation

6 Pages

-

2017 SWK PDM

4 Pages

-

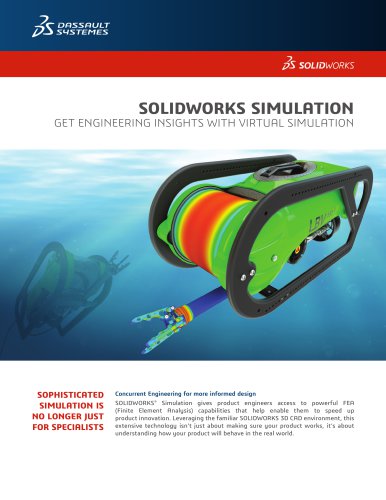

SOLIDWORKS Simulation_2016

6 Pages

-

SOLIDWORKS Subscription

2 Pages

-

SOLIDWORKS PREMIUM_2015

6 Pages

-

SOLIDWORKS Simulation Suite

4 Pages

-

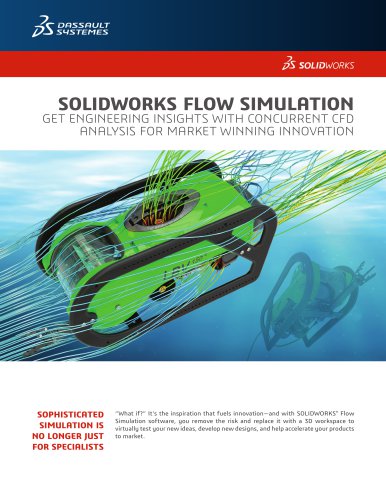

SOLIDWORKS Flow Simulation

4 Pages

-

SOLIDWORKS CircuitWorks

4 Pages

-

SOLIDWORKS EPDM

4 Pages

-

SolidWorks Simulation_2014

6 Pages

-

DRAFTSIGHT

2 Pages

-

SW2014 Datasheet EPDM

4 Pages

-

SW2014 Datasheet Top Ten

2 Pages

-

SolidWorks Premium_2013

8 Pages

-

SOLIDWORKS SIMULATION 2010

6 Pages

-

EPDM

4 Pages

-

hcv

2 Pages

-

em

2 Pages

-

SW_Electrical_DS_2013

4 Pages

-

SOLIDWORKS PREMIUM 2011

4 Pages

-

SolidWorks Routing

2 Pages

-

PhotoWorks Product Overview

2 Pages

-

COSMOSWorks Designer

2 Pages

-

SolidWorks 2008

2 Pages