Catalog excerpts

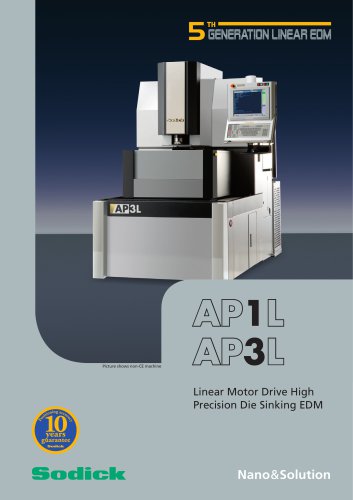

Die Sinker EDM Hybrid Wire > AG35L K1BLK1C Small Hole MachineElectron Beam PIKA Finish Machine > K3HN EB300 AG55LAQ15L AP1L PremiumAD3L saving Lower ecological impact due to energy saving technologies incorporated in all SODICK products. energy 3 size="-3">

Open the catalog to page 3

Sodicks linear motor technology provides instantaneous reaction time which maximises cutting efficiency. As there are no ball screws or couplings, backlash is totally eliminated. This provides several advantages, including improved positioning and cutting accuracy, while providing smooth and vibration free table movement.With SodickҒs new LP Control, Parasolid files (solid models) can be directly imported into the control. This maximises cutting efficiency, reduces workflow and programming errors. Linear High Speed Wire Cut EDM AQ327L/AQ537L with LP Control > The worlds fastest and most...

Open the catalog to page 4

Sodick Wire Cut EDM Series > Sodick's development of core technologies has led to world record achievements in high speed precision machining. Sodick's design uses ceramics for the key com- ponents of the machine tool and implements the latest CAD design technology. However, Sodick does not lose sight of proven traditional methods, such as the scraping of all mating surfaces, to perfect the high rigidity of the basic machine structure. Furthermore the Wire Cut EDM range from Sodick comes with the World's First 10-Year Positioning Accuracy Guarantee. High Rigidity Structure > Sodick's...

Open the catalog to page 6

The LP power supply comes equipped with Intelligent Q > 3 vicԓ as standard. This enables the operator to directly import 3D models and to additionally extract every cutting contour to be wire EDM'd within seconds. Even work pieces with a complicated shape and different cutting heights can be programmed using only a single command. After the surfaces to be machined have been recognised, an NC programme is generated including all cutting parameters. A full on screen simulation is possible prior to machining. > All LP series machines come with Intelligent Q > 3 vicԓ and Espritԓ on a CD ROM....

Open the catalog to page 7

Sodick linear motors for CNC die sinkers reduce EDM machining time by up to 80%. As there are no ball screws or couplings, back lash is totally eliminated. The menu driven control automatically writes the NC code for the operator whilst inserting optimum cutting conditions. With instantaneous linear motor responsive control the need for flushing is eliminated making the impossible possible. Using Sodicks new LP control you can import Parasolid files (solid models). This feature maximises the cutting performance, reduces the workflow and eliminates programming errors. Linear Micro-Precision...

Open the catalog to page 8

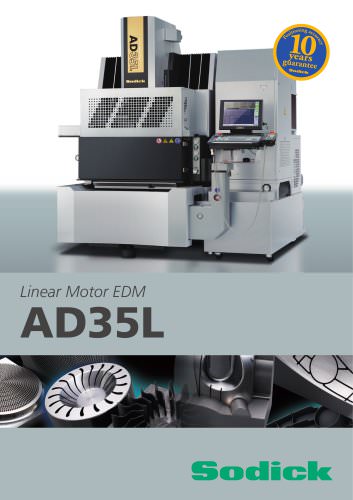

Linear Entry Die Sinker EDM AD3L > Without compromised performance, but at a competitive price, the AD3L makes the performance of linear motor drive machines available to a greater number of customers. The generator comes complete with SVC and SGF circuit as standard. The high speed linear motors maintain the optimal discharge gap and significantly increase discharge frequency to achieve the worlds highest machining speed. Linear Ultra Large Die Sinker EDM AQ15L > An ultra large die sinker EDM specialising in the highly efficient production of large size moulds such as those for automobile...

Open the catalog to page 9

The World's First 10-Year Positioning Accuracy Guarantee > The linear motor-driven EDMs are completely free from the deterioration in machining accuracy caused by worn ball screws throughout the machine life. This enables Sodick to offer a unique 10 year precision accuracy guarantee.Linear motor drives on Sodick die-sinker and wire-cut EDMs have enabled difficult machining operations that were not possible with conventional ball screw-type machines. This exceptional performance has resulted in cumulative sales of over 20,000 units by 2008. ҔLP Series Power Supply Unit > An NC system based...

Open the catalog to page 10

email europe@sodick.eu.com online www.sodick.org >

Open the catalog to page 12All Sodick catalogs and technical brochures

-

ALC Series

24 Pages

-

Linear Product Range 2019

28 Pages

-

HS430L

2 Pages

-

HS650L

2 Pages

-

UH430L/UH650L

16 Pages

-

AQ1200L Premium

2 Pages

-

AQ900L Premium

2 Pages

-

OPM250L

24 Pages

-

Produkt Range Brochure

28 Pages

-

ALC600G

2 Pages

-

ALC400G

2 Pages

-

OPM350L

2 Pages

-

AP250L

2 Pages

-

AQ1500L

2 Pages

-

AQ1200L

2 Pages

-

AQ750L

2 Pages

-

SLC600G

2 Pages

-

SLC400G

2 Pages

-

AP3L

2 Pages

-

AQ15L

2 Pages

-

AG100L

2 Pages

-

AG80L LST

2 Pages

-

AG40L

2 Pages

-

AD35L

2 Pages

-

AP1L

2 Pages

-

K1C/K3HN

4 Pages

-

VL400Q/VL600Q

4 Pages

-

Linear Product Range

24 Pages

-

AG80L LST / AG100L

4 Pages

-

AQ15L / AQ20L

4 Pages

-

AG40L/AG60L/AG80L

16 Pages

-

AD35L / AD55L

4 Pages

-

ad55l

2 Pages

-

aq20l

2 Pages

-

AP250 L

6 Pages

-

SLC-G Series

8 Pages

-

VZ300L/VZ500L

6 Pages

-

Linear EDM Range

20 Pages

Archived catalogs

-

AP1L/AP3L

8 Pages

-

Linear Motor EDM AD35L

4 Pages

-

SLG

8 Pages

-

SLQ

2 Pages

-

AQ400L

8 Pages

-

VZ300L

2 Pages

-

AQ45L

6 Pages

-

AD30L

6 Pages

-

Product Range

6 Pages

-

Sodick - Linear Motor Wire EDM

13 Pages

-

Sodick - Linear Motor Sinker EDM

12 Pages

-

Sodick - High Speed Hard Milling

22 Pages

-

Sodick - Small Hole EDM

6 Pages