Catalog excerpts

Large Size Linear Wire-cut EDM

Open the catalog to page 1

Linear Large Wire EDM Range As a response to the growing demands for Large Wire EDM Machines resulting from the growth in Aerospace, Large Mold and Dies stimulated by the popularity of Large Flat Screen TV’s and the growth in large Automotive Tooling; Sodick has expanded its range of Large Size Wire EDM Machines. The AQ750L/900L/1200L/AQ1500L utilize the Linear Motor Technology developed and manufactured by Sodick to ensure smooth and accurate motion. The LP Control is capable of directly importing a 3D Model, therefore helping operators to achieve optimum productivity during the...

Open the catalog to page 2

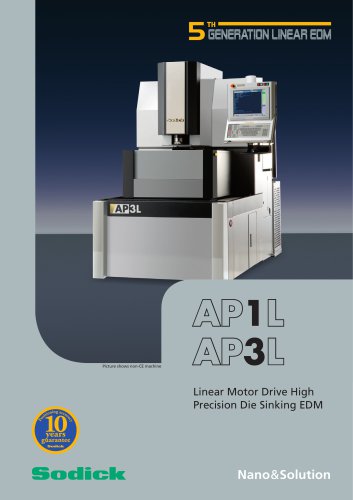

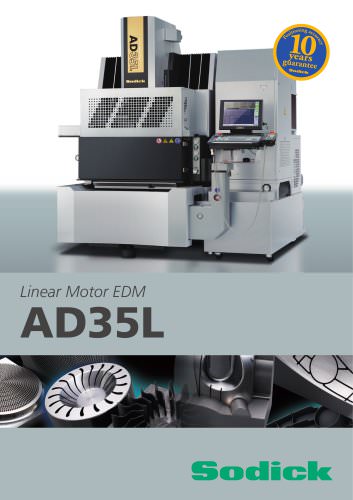

Linear Series Utilising Linear Motor Drive Systems, Sodick Die-Sinker and Wire-Cut EDM Machines have enabled customers to achieve EDM machining standards that are not possible with conventional ball-screw type machines. The Linear Motor Driven EDM Machines do not suffer the disadvantages associated with conventional ball screw type machines. The use of the Linear Motor System removes the deterioration of the machining accuracy due to Backlash and Lost Motion as a result of wear within the ball-screw assembly. Sodick is so condent of the reliability and accuracy of their machines over the...

Open the catalog to page 3

Five Core Technologies Developed in-House Aiming At Manufacturing At The World’s Highest Level. Starting from the development of the electrical discharge circuits, Sodick has continued to pursue the highest possible level of accuracy, speed and efciency of machining. As a result the technologies for the CNC Units, ne Ceramics, Linear Motors, Motion Controllers and the Electrical Discharge Power Supply have been established as the 5 Core Technologies of Sodick. Sodick’s continuous research programme into these core areas and new technologies ensures Sodick remains at the forefront of EDM...

Open the catalog to page 4

Sodick’s Intelligent Q3vic Shapes The Future Of Manufacturing The use of 3D Solid Models has now become an essential part of the manufacturing process. The AQ750L/900L/1200L/AQ1500L Range features a powerful Control Unit compatible with 3D Solid Models. These machines provide customers with the manufacturing technologies capable of producing results which are not totally dependent on the level of skill of the operator; effectively eliminating the need for drawings and reducing the chances of human error. Intelligent Q3vic The LP2WH power supply comes with “Intelligent Q³Vic” as standard....

Open the catalog to page 5

Design Features that ensure continuous and unattended production. High Speed Generator The LP2WH High Speed Generator is standard on the Sodick AQ Series. Both brass and coated-wire are compatible with this advanced Generator. Jumbo Feeder Low Maintenance Tank Seal This wire supply device allows up to a 20kg wire bobbin and enables continuous machining. The tank seal flushing function has been introduced to enhance the capability and reliability. The constant flushing stops the possibility build-up of debris on the rear seal. The High Speed Automatic Wire Threader (AWT) The High Speed...

Open the catalog to page 6

Specications Machine tool Max. workpiece dimensions (W x D x H) mm Max. workpiece weight X-/Y- Z- axis travel U x V axis travel Taper angle (Work. thickness 150mm) Wire diameter Wire tension Max. wire speed Distance from floor to table top Machine tool dimensions (W x D x H) mm Machine installation dimensions Machine tool weight Total power input Dielectric Tank Capacity Dielectric fluid filtration system Deionizer Replaceable paper filters (internal pressure) Ion exchange resin (18-lit. type) Replaceable paper filters (internal pressure) Ion exchange resin (18-lit. type) Replaceable paper...

Open the catalog to page 7

create your future Sodick Europe Ltd. Sodick Contact Rowley Drive, Baginton Coventry, CV3 4FG United Kingdom Phone +44 (0) 24 7621 4314 email europe@sodick.eu.com online www.sodick.org

Open the catalog to page 8All Sodick catalogs and technical brochures

-

ALC Series

24 Pages

-

Linear Product Range 2019

28 Pages

-

HS430L

2 Pages

-

HS650L

2 Pages

-

UH430L/UH650L

16 Pages

-

AQ1200L Premium

2 Pages

-

AQ900L Premium

2 Pages

-

OPM250L

24 Pages

-

Produkt Range Brochure

28 Pages

-

ALC600G

2 Pages

-

ALC400G

2 Pages

-

OPM350L

2 Pages

-

AP250L

2 Pages

-

AQ1500L

2 Pages

-

AQ1200L

2 Pages

-

AQ750L

2 Pages

-

SLC600G

2 Pages

-

SLC400G

2 Pages

-

AP3L

2 Pages

-

AQ15L

2 Pages

-

AG100L

2 Pages

-

AG80L LST

2 Pages

-

AG40L

2 Pages

-

AD35L

2 Pages

-

AP1L

2 Pages

-

K1C/K3HN

4 Pages

-

VL400Q/VL600Q

4 Pages

-

Linear Product Range

24 Pages

-

AG80L LST / AG100L

4 Pages

-

AQ15L / AQ20L

4 Pages

-

AG40L/AG60L/AG80L

16 Pages

-

AD35L / AD55L

4 Pages

-

ad55l

2 Pages

-

aq20l

2 Pages

-

AP250 L

6 Pages

-

SLC-G Series

8 Pages

-

VZ300L/VZ500L

6 Pages

-

Linear EDM Range

20 Pages

Archived catalogs

-

AP1L/AP3L

8 Pages

-

Linear Motor EDM AD35L

4 Pages

-

SLG

8 Pages

-

SLQ

2 Pages

-

AQ400L

8 Pages

-

VZ300L

2 Pages

-

AQ45L

6 Pages

-

AD30L

6 Pages

-

Product Range

6 Pages

-

Sodick - Linear Motor Wire EDM

13 Pages

-

Sodick - Linear Motor Sinker EDM

12 Pages

-

Sodick - High Speed Hard Milling

22 Pages

-

Sodick - Small Hole EDM

6 Pages