Catalog excerpts

apan made products Linear Motor Drive Precision Metal 3D Printer

Open the catalog to page 1

Experience Creating the Future apan made products The new shape is made with grown technology. ew Creat New Form. Create your future with Sodick precision metal 3D printer. he Sodick “OPM Series” OPM250L and OPM 350L precision metal 3D printers are an innovative manufacturing system capable of producing one-piece metal molds, fundamentally changing how molds for plastic products are created. With enhanced productivity, reduced lead times, and substantial cost reduction for molded products, the system achieves levels of performance not possible on conventional production systems. Moreover,...

Open the catalog to page 2

Precision Metal 3D Printer

Open the catalog to page 3

ne Stop Solu Machining Center In addition to our proven linear motor and high-speed milling technologies, the UH Series offers practical machining simulation software and an ergonomic, curved design. Through full linear motor operation, Sodick machining centers achieve high-speed, high- apan made products precision, high-quality machining. Sodick proudly introduces practical one-stop metal 3D printing solutions. 4 he OPM Series precision metal 3D printers allow us to offer an industry-leading “onestop solution.” Sodick provides integrated support for all processes, from design to molding,...

Open the catalog to page 4

Die-Sinker EDM The new “Arc-less Plus” electrical discharge machining system by substantially shortening machining times and reducing Precision Metal 3D Printer the number of electrodes required. Moreover, the SVC circuit The OPM Series performs continuous laser machining and high-speed milling in a single machine. rapidly creates high- quality satin or mirror surfaces. A uniform layer of metal powder is melted and solidified through direct metal laser sintering. This is installed standard, lowering overall costs and human errors is then precision machined by high-speed milling to create a...

Open the catalog to page 5

Machining Methods Additive Manufacturing with Sodick’s Precision Metal 3D Printer The OPM Series is an automated machine that melts and solidifies a uniform layer of metal powder in a process called laser sintering. The machines then engage in high-speed milling for highly accurate finishing. Sodick proudly achieves metal 3D printing through the use of a 500W fiber laser for the melting and solidifying metal powder. After each layer is fully machined, the workspace is recoated with metal powder and the process is repeated. Laser machining 10 passes Milling is performed after 10 laser...

Open the catalog to page 6

Precision Metal 3D Printer Metal 3D printing intermediate stage Mold with cooling channels

Open the catalog to page 7

Technical Excellence Sodick In-house Developed and Manufactured New NC Unit and OS-FLASH Dedicated CAM After designing a mold with 3D cooling channels using CAD software, a plastic temperature simulation is performed using CAE. Next, the optimized 3D CAD data is loaded into the "OS-FLASH" dedicated CAM system, which creates the NC program and directly supplies it to the LN4RP NC unit. Setup screen Laser machining screen Tool management screen Easily configure the settings before mold manufacturing. Production data can be imported by simple drag and drop procedure. Shows laser machining...

Open the catalog to page 8

All elemental technologies developed and manufactured by Sodick ore Technology development of all core technologies Precision Metal 3D Printer High-Speed Cutting Chamber Technology Sodick has fostered a line of high-speed, high-accuracy cutting Sodick is an expert in vacuum chamber design, with over 10 years technology over the years using high-speed milling center of production experience. First designed in 2003, Sodick’s vacuum developed in-house. chamber technology has been tested in the PF00A/PF32A Electron The OPM Series permits stable finishing for a wide range of Beam PIKA Finish...

Open the catalog to page 9

Mold Internet of Things (ioT) Management EDI Process management by Create NC program a scheduler compatible -> Transfer to machine with Sodick machines Consolidate management Error notification of machine operation, analyze and use the acquired data Unmanned and Automated Control, Remote Operation The expertise of experienced engineers was indispensable for conventional mold manufacturing, which required complex processes, numerous parts, and multiple machine tools. Today, however, the OPM Series may be the only machines that encompasses a full production system to manufacture...

Open the catalog to page 10

High-Quality Machining to Create Mold IoT Mold manufacture requires a high sintered density (99.9% melting ratio) and highly accurate machining. The OPM Series meets both criteria, permitting finishing (SPI-A2 class) not possible with a conventional metal 3D printer. Test Machining to Check Accuracy Required precision of ±1/100 mm in maraging steel All shapes were achieved. Precision Metal 3D Printer

Open the catalog to page 11

OPM Series: Plastic Molding Revol (OPM250L / OPM350L) 3D modeled cooling channels Investigate mold design Propose areas of improvement Uniform, high-quality production control (mold IoT) from a remote location High-precision machining of freely configured, one-piece molds Moldex3D plastic injection molding simulation software (Core Tech System Co., Ltd.) permits the 3D arrangement of cooling channels which can normally be arranged in two dimensions only. It also performs simulation of molded products during injection molding. Side-by-side comparisons with conventional molds confirm that...

Open the catalog to page 12

When plastic products are injection molded, the molding performance is significantly affected by the construction of the mold used. Temperature control inside the mold is always a critical element in this aspect. The OPM Series can produce molds with 3D cooling channels freely positioned inside, eliminating uneven temperatures within the mold. It allows an ultra-high cycle rate that was impossible with a conventional mold and permits optimization of the molding shrinkage. As a bonus, these process improvements reduce the lead time by half or more. Cooling channel design OPM mold design...

Open the catalog to page 13All Sodick catalogs and technical brochures

-

ALC Series

24 Pages

-

Linear Product Range 2019

28 Pages

-

HS430L

2 Pages

-

HS650L

2 Pages

-

UH430L/UH650L

16 Pages

-

AQ1200L Premium

2 Pages

-

AQ900L Premium

2 Pages

-

Produkt Range Brochure

28 Pages

-

ALC600G

2 Pages

-

ALC400G

2 Pages

-

OPM350L

2 Pages

-

AP250L

2 Pages

-

AQ1500L

2 Pages

-

AQ1200L

2 Pages

-

AQ750L

2 Pages

-

SLC600G

2 Pages

-

SLC400G

2 Pages

-

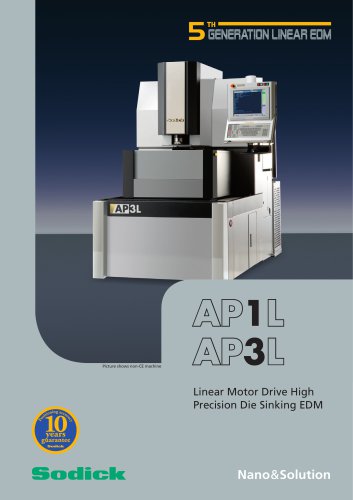

AP3L

2 Pages

-

AQ15L

2 Pages

-

AG100L

2 Pages

-

AG80L LST

2 Pages

-

AG40L

2 Pages

-

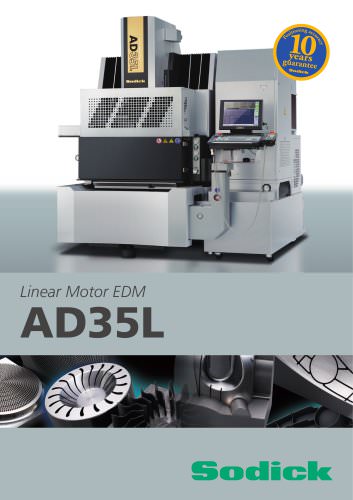

AD35L

2 Pages

-

AP1L

2 Pages

-

K1C/K3HN

4 Pages

-

VL400Q/VL600Q

4 Pages

-

Linear Product Range

24 Pages

-

AG80L LST / AG100L

4 Pages

-

AQ15L / AQ20L

4 Pages

-

AG40L/AG60L/AG80L

16 Pages

-

AD35L / AD55L

4 Pages

-

ad55l

2 Pages

-

aq20l

2 Pages

-

AP250 L

6 Pages

-

SLC-G Series

8 Pages

-

VZ300L/VZ500L

6 Pages

-

Linear EDM Range

20 Pages

Archived catalogs

-

AP1L/AP3L

8 Pages

-

Linear Motor EDM AD35L

4 Pages

-

SLG

8 Pages

-

SLQ

2 Pages

-

AQ400L

8 Pages

-

VZ300L

2 Pages

-

AQ45L

6 Pages

-

AD30L

6 Pages

-

Product Range

6 Pages

-

Sodick - Linear Motor Wire EDM

13 Pages

-

Sodick - Linear Motor Sinker EDM

12 Pages

-

Sodick - High Speed Hard Milling

22 Pages

-

Sodick - Small Hole EDM

6 Pages