Catalog excerpts

New Features Support Cost Effective Machining Sodick's expertise in EDM innovation using 3D design systems, the latest CAE technologies and numerous simulations have made it possible to create an improved basic machine structure of optimised rib arrangements which increase rigidity by approximately 70%. Using the new design, machine deformation is minimised, allowing optimum performance at high-speed and rapid acceleration linear motors. Furthermore the original design of an independent X and Y-axis plus an efficient machine layout leads to a longer stroke, smaller footprint and highly...

Open the catalog to page 2

High-Rigidity Machine Structure The machine structure has been designed to ensure optimum strength and rigidity. It features a symmetrical machine design to guarantee stability and eliminate the detrimental effects of vibration caused by machine axis movements and thermal influences. A Highly rigid direct guide is employed on Y-axis for further rigidity. The generator and machine body are enclosed within a single footprint, reducing the space requirement and ensuring the installation is quick and easy.

Open the catalog to page 3

Core Technologies For Outstanding Performance In-House Developed Linear Motor Drive Sodick's in-house developed linear motor is a direct drive, vibration free device which has unrivalled acceleration and positioning accuracy with no backlash. It's high dynamic responsiveness, stability for precision machining, and perfor- mance do not diminish over time and remain maintenance free. The linear motor achieves even better performance thanks to (K-SMC) which Sodick Linear Motor Drive Conventional Ball Screw Advanced Components AQ45L is constructed using ceramic components for the Z-Axis quill...

Open the catalog to page 4

900 1357 2520 2099 2361 Keyboard-shaped Electrode No Flushing Cutting Time Surface Workpiece Cutting Depth Electrode 8h 5min 0.3μmRa Steel (1.2344) 9mm Cu

Open the catalog to page 5

Linear Motor Drive All CE spec machines have external transformer with dimension of ca. 650 x 460 x 540mm Work table size(WxD) Work tank inner dimensions Work tank fluid level Work tank capacity Maximum weight of work piece Maximum weight of electrode Distance from floor to table top Machine weight Total power input *340 mm when fitted with ATC Standard Features Linear Motor on X, Y, Z-axis Linear glass scale on X, Y, Z-axis Ceramic components Dielectric chiller SGF Nano wear generator 15" Touch screen display Due to ongoing research, specifications are subject to change without prior...

Open the catalog to page 6All Sodick catalogs and technical brochures

-

ALC Series

24 Pages

-

Linear Product Range 2019

28 Pages

-

HS430L

2 Pages

-

HS650L

2 Pages

-

UH430L/UH650L

16 Pages

-

AQ1200L Premium

2 Pages

-

AQ900L Premium

2 Pages

-

OPM250L

24 Pages

-

Produkt Range Brochure

28 Pages

-

ALC600G

2 Pages

-

ALC400G

2 Pages

-

OPM350L

2 Pages

-

AP250L

2 Pages

-

AQ1500L

2 Pages

-

AQ1200L

2 Pages

-

AQ750L

2 Pages

-

SLC600G

2 Pages

-

SLC400G

2 Pages

-

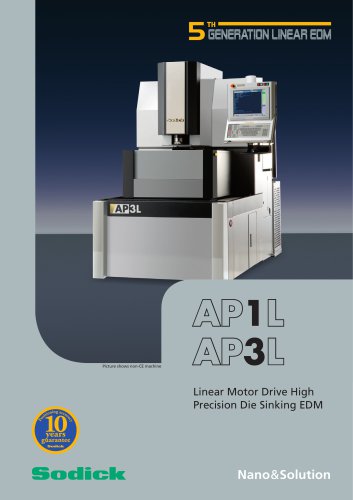

AP3L

2 Pages

-

AQ15L

2 Pages

-

AG100L

2 Pages

-

AG80L LST

2 Pages

-

AG40L

2 Pages

-

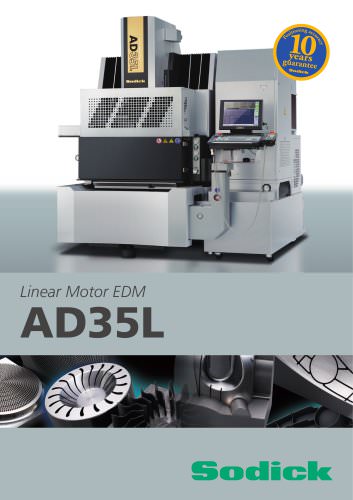

AD35L

2 Pages

-

AP1L

2 Pages

-

K1C/K3HN

4 Pages

-

VL400Q/VL600Q

4 Pages

-

Linear Product Range

24 Pages

-

AG80L LST / AG100L

4 Pages

-

AQ15L / AQ20L

4 Pages

-

AG40L/AG60L/AG80L

16 Pages

-

AD35L / AD55L

4 Pages

-

ad55l

2 Pages

-

aq20l

2 Pages

-

AP250 L

6 Pages

-

SLC-G Series

8 Pages

-

VZ300L/VZ500L

6 Pages

-

Linear EDM Range

20 Pages

Archived catalogs

-

AP1L/AP3L

8 Pages

-

Linear Motor EDM AD35L

4 Pages

-

SLG

8 Pages

-

SLQ

2 Pages

-

AQ400L

8 Pages

-

VZ300L

2 Pages

-

AD30L

6 Pages

-

Product Range

6 Pages

-

Sodick - Linear Motor Wire EDM

13 Pages

-

Sodick - Linear Motor Sinker EDM

12 Pages

-

Sodick - High Speed Hard Milling

22 Pages

-

Sodick - Small Hole EDM

6 Pages