Catalog excerpts

Eco Cut O: The Revolution – Oil Cutting Speed = Water Cutting Speed Linear Motor Drive High Precision Wire-Cut EDM Sodick’s latest innovation ECO Cut O makes it possible for Oil Dielectric to realize the same cutting speeds as Water Dielectric in achieving a surface finish of 0.15µmRa and beyond. 1860 Surface Roughness Side View Precision machining/Fine wire Oil submerged high speed range Water submerged high speed range Front View Fire extinguisher Water: Standard Condition Manual start switch for Fire extinguisher Manual start switch 2395 for Fire extinguisher All the CE machines have external transformer with dimension of approx. 650 x 460 x 540 mm 1875 Taper angle (Work. thickness 100mm) Wire diameter Wire tension Distance from floor to table top Machine tool dimensions (W x D x H) EDM is a machining method of removing material by discharge heat, by which its surface is melted and vaporized. When Tungsten Carbide (WC) materials are processed in water dielectric, the cobalt, the bonding material, is depleted. This results in lowering the hardness of the material surface. On the other hand, cobalt depletion is eliminated in oil dielectric. Thanks to the recast layer, its surface is hardened and increases the life of the tool. Furthermore, another advantage of oil dielectric is rust protection of the workpiece. It can also reduce the consumption of filters because of smaller spark gap and therefore removed material. Advanced Oil-Based Wire EDM Technology Fast machining/Regular wire Cutting Time Max. workpiece height (WxDxH) 2395 x 2692 x 2095 mm (incl. power supply, dielectric tank, and wire bucket) Machine weight 3900 kg (Incl. CNC and Dielectric tank) Total power input Work Table Standard Features Material: WC (Cemented carbide)/G5 Thickness: 80 mm Surface finish: 0.06µmRa Dielectric tank Dielectric fluid Thermally stable machine construction Tension servo Fluid filtration method (Oil) FT II (Fine Pick-up Function) Energy saving circuit Linear Motor (X,Y,U,V axis) Replaceable paper filter (One inner pressure cylinder type) Dielectric cooling unit Linear scale (X,Y,U,V axis) Replaceable paper filter (Two inner pressure cylinder type) Fluid filtration method (Water) 1 Gbit/sec communication technology Dielectric fluid capacity The Oil based machining enables fine control of the discharge gap, achieving a surface quality of 0.02µmRa AWT (Automatic Wire Threader) (Air pressure 0.5 MPa is required) Ceramic Components Picture shows non-CE machine Linear Motor Drive High Precision Wire-Cut EDM Machine specifications are subject to change without prior notice. create your future 0.1mm Material: WC (Cemented carbide)/G5 Thickness: 5 mm Surface finish: 0.05µmRa Sodick Europe Ltd. Material: WC (Cemented carbide) Thickness: 20 mm Surface finish: 0.02µmRa Electrode: ø0.2mm Rowley Drive, Baginton Coventry, CV3 4FG United Kingdom Sodick Contact Phone Fax email europe@sodick.eu.com online www.sodick.org

Open the catalog to page 1

Oil Cutting Technology Since 1981 Sodick has developed the cutting technology in oil dielectric since 1981. Wire EDM with Oil dielectric has always been the best solution for high-accuracy and high quality surface finish because of the smaller discharge (spark) gap. On the other hand, the smaller gap always had resulted in slower cutting speed. Thanks to Sodick's know-how and experience through years, Sodick has now developed a new generator “ECO Cut O”. ECO Cut O realizes further improvement on cutting speed and number of cuts with oil dielectric. To achieve the surface finish of less than...

Open the catalog to page 2

Oil Cutting Technology Since 1981 Sodick has developed the cutting technology in oil dielectric since 1981. Wire EDM with Oil dielectric has always been the best solution for high-accuracy and high quality surface finish because of the smaller discharge (spark) gap. On the other hand, the smaller gap always had resulted in slower cutting speed. Thanks to Sodick's know-how and experience through years, Sodick has now developed a new generator “ECO Cut O”. ECO Cut O realizes further improvement on cutting speed and number of cuts with oil dielectric. To achieve the surface finish of less than...

Open the catalog to page 3

Oil Cutting Technology Since 1981 Sodick has developed the cutting technology in oil dielectric since 1981. Wire EDM with Oil dielectric has always been the best solution for high-accuracy and high quality surface finish because of the smaller discharge (spark) gap. On the other hand, the smaller gap always had resulted in slower cutting speed. Thanks to Sodick's know-how and experience through years, Sodick has now developed a new generator “ECO Cut O”. ECO Cut O realizes further improvement on cutting speed and number of cuts with oil dielectric. To achieve the surface finish of less than...

Open the catalog to page 4

Eco Cut O: The Revolution – Oil Cutting Speed = Water Cutting Speed Linear Motor Drive High Precision Wire-Cut EDM Sodick’s latest innovation ECO Cut O makes it possible for Oil Dielectric to realize the same cutting speeds as Water Dielectric in achieving a surface finish of 0.15µmRa and beyond. 1860 Surface Roughness Side View Precision machining/Fine wire Oil submerged high speed range Water submerged high speed range Front View Fire extinguisher Water: Standard Condition Manual start switch for Fire extinguisher Manual start switch 2395 for Fire extinguisher All the CE machines have...

Open the catalog to page 5

Eco Cut O: The Revolution – Oil Cutting Speed = Water Cutting Speed Linear Motor Drive High Precision Wire-Cut EDM Sodick’s latest innovation ECO Cut O makes it possible for Oil Dielectric to realize the same cutting speeds as Water Dielectric in achieving a surface finish of 0.15µmRa and beyond. 1860 Surface Roughness Side View Precision machining/Fine wire Oil submerged high speed range Water submerged high speed range Front View Fire extinguisher Water: Standard Condition Manual start switch for Fire extinguisher Manual start switch 2395 for Fire extinguisher All the CE machines have...

Open the catalog to page 6All Sodick catalogs and technical brochures

-

ALC Series

24 Pages

-

Linear Product Range 2019

28 Pages

-

HS430L

2 Pages

-

HS650L

2 Pages

-

UH430L/UH650L

16 Pages

-

AQ1200L Premium

2 Pages

-

AQ900L Premium

2 Pages

-

OPM250L

24 Pages

-

Produkt Range Brochure

28 Pages

-

ALC600G

2 Pages

-

ALC400G

2 Pages

-

OPM350L

2 Pages

-

AP250L

2 Pages

-

AQ1500L

2 Pages

-

AQ1200L

2 Pages

-

AQ750L

2 Pages

-

SLC600G

2 Pages

-

SLC400G

2 Pages

-

AP3L

2 Pages

-

AQ15L

2 Pages

-

AG100L

2 Pages

-

AG80L LST

2 Pages

-

AG40L

2 Pages

-

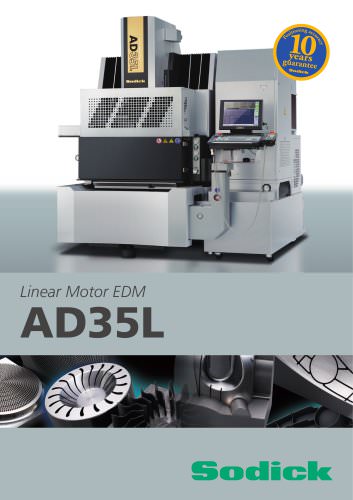

AD35L

2 Pages

-

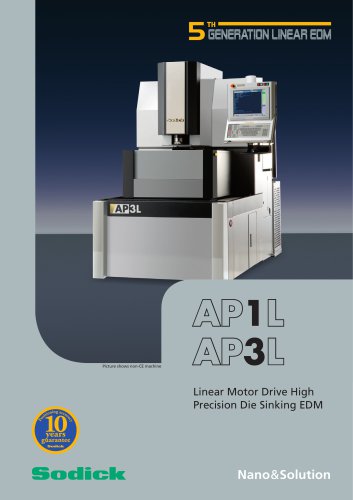

AP1L

2 Pages

-

K1C/K3HN

4 Pages

-

VL400Q/VL600Q

4 Pages

-

Linear Product Range

24 Pages

-

AG80L LST / AG100L

4 Pages

-

AQ15L / AQ20L

4 Pages

-

AG40L/AG60L/AG80L

16 Pages

-

AD35L / AD55L

4 Pages

-

ad55l

2 Pages

-

aq20l

2 Pages

-

SLC-G Series

8 Pages

-

VZ300L/VZ500L

6 Pages

-

Linear EDM Range

20 Pages

Archived catalogs

-

AP1L/AP3L

8 Pages

-

Linear Motor EDM AD35L

4 Pages

-

SLG

8 Pages

-

SLQ

2 Pages

-

AQ400L

8 Pages

-

VZ300L

2 Pages

-

AQ45L

6 Pages

-

AD30L

6 Pages

-

Product Range

6 Pages

-

Sodick - Linear Motor Wire EDM

13 Pages

-

Sodick - Linear Motor Sinker EDM

12 Pages

-

Sodick - High Speed Hard Milling

22 Pages

-

Sodick - Small Hole EDM

6 Pages