Catalog excerpts

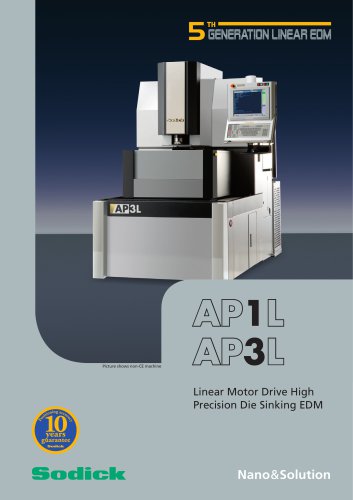

Picture shows non-CE machine Linear Motor Drive High

Open the catalog to page 1

The World's First 10-Year Positioning Accuracy Guarantee Utilising the linear motor drive system, Sodick die-sinker EDMs and wire-cut EDMs have enabled difficult machining operations that were not possible with conventional ball screw-type EDMs, resulting in the cumulative shipment of more than 27,000 units by early 2011. The linear motor-driven EDM, eliminates the need for ball screws and allows for non-contact motion. Use of the Linear Motor removes the deterioration in machining accuracy caused by the worn ball screw assemblies throughout the machine life. Sodick’s confidence in the...

Open the catalog to page 2

Sodick's Linked Process: Manufacturing of Side-View LED 1: Core Pin Block 2: Drilling Of Start Hole 2 workpieces with 64 pins each are processed by single tool achieving surface finish of 0.028µmRa. 32 start-holes are made by K3BL on a workpiece. Thanks to the oil dielectric, workpiece is protected from corrosion/rust. Workpiece: ELMAX (HR60) | 20x20x25 mm Spindle: Max. 40,000 rpm Cutting Tool: cBN Radial ø 0.5, R 0.02 Cutting Time: 5 min 14sec/piece Bottom Corner Radius: < 0.03 mm Workpiece: ELMAX (HR60) | Height of 20 mm Electrode Material: Cu Pipe | Cutting Time: 4 min/hole Electrode...

Open the catalog to page 3

Five Core Technologies Developed In-House For Achieving The World's Highest Quality Machining Starting with the development of electrical discharge circuits, Sodick has continued to make untiring efforts in the research and development of advanced EDMs. Sodick’s philosophy has been the pursuit of the highest level of accuracy, speed and versatility of machining in order to provide the highest quality products to its customers. Sodick's: Power Supply Units, Discharge Units, Linear Motors, Motion Controllers and Fine Ceramic Components have evolved as its five core technologies. These...

Open the catalog to page 4

Ceramic Components In major components, such as quill and table, the Sodick Die Sinker EDM series is equipped with in-house made ceramic material, which has been carefully researched and is considered as the best material for use in high-end EDM machines. Advantages Of Ceramic Material 1) hen it is used in moving components, such as the quill, the low density is W effective in weight reduction, leading to increased dynamic response, resulting in superior machined surface quality. 2) he low co-efficient of linear thermal expansion minimises the thermal T deformation caused by changing...

Open the catalog to page 5

Options Super-High Precision Rotary Head, “R Head” Sodick’s in-house made super-high precision rotary head “R Head” is designed and developed only for the Sodick AP sinker EDM range. The spindle is capable of rotation speed up to 2,000rpm with resolution of 1,048,576 divisions. Resolution Min. increment Positioning Speed Spindle Speed Max. Electrode Weight Automatic Tool Changers Automatic Tool Changer (ATC) is available on AP1L and AP3L. 8-station ATC is available on AP1L and 24 or 48-station ATC is available on AP3L. Furthermore, both machines are compatible with Robot system as an...

Open the catalog to page 6

Specification Machine Tool Ceramic table dimensions Dielectric level (min~max, mm) Step resolution Distance from floor to table top Machine tool dimensions (W x D x H) Incl. power supply and dielectric tank Machine installation space (W×D) (including maintenance space) Machine weight Controlled axis Resolution C Axis (optional) Rotational speed C Axis (optional) Dielectric Tank Dielectric fluid Replaceable paper filter (MF-1530P) Replaceable paper filter (MF-1530P) Filtration method CNC Power Supply LN2/LN20 Max. machining current Offset settings storage capacity Discharging power supply...

Open the catalog to page 7

Side Cooling Unit 360 Power Supply Dielectric Tank 415 Coil Cooling Dielectric tank Power Supply Dielectric Tank Coil cooling Coil Cooling Pomp Unit Power Supply 480 Power Supply Dielectric Tank Coil Cooling Coil cooling Pump unit · All CE spec machines have external transformer with dimension of ca. 650 x 460 x 540mm create your future Sodick Europe Ltd. Sodick Contact Rowley Drive, Baginton Coventry, CV3 4FG United Kingdom Phone +44 (0) 24 7621 4314 email europe@sodick.eu.com online www.sodick.org

Open the catalog to page 8All Sodick catalogs and technical brochures

-

ALC Series

24 Pages

-

Linear Product Range 2019

28 Pages

-

HS430L

2 Pages

-

HS650L

2 Pages

-

UH430L/UH650L

16 Pages

-

AQ1200L Premium

2 Pages

-

AQ900L Premium

2 Pages

-

OPM250L

24 Pages

-

Produkt Range Brochure

28 Pages

-

ALC600G

2 Pages

-

ALC400G

2 Pages

-

OPM350L

2 Pages

-

AP250L

2 Pages

-

AQ1500L

2 Pages

-

AQ1200L

2 Pages

-

AQ750L

2 Pages

-

SLC600G

2 Pages

-

SLC400G

2 Pages

-

AP3L

2 Pages

-

AQ15L

2 Pages

-

AG100L

2 Pages

-

AG80L LST

2 Pages

-

AG40L

2 Pages

-

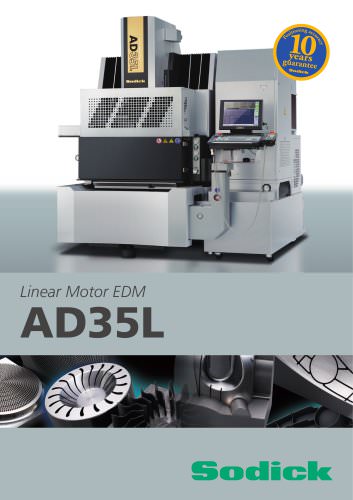

AD35L

2 Pages

-

AP1L

2 Pages

-

K1C/K3HN

4 Pages

-

VL400Q/VL600Q

4 Pages

-

Linear Product Range

24 Pages

-

AG80L LST / AG100L

4 Pages

-

AQ15L / AQ20L

4 Pages

-

AG40L/AG60L/AG80L

16 Pages

-

AD35L / AD55L

4 Pages

-

ad55l

2 Pages

-

aq20l

2 Pages

-

AP250 L

6 Pages

-

SLC-G Series

8 Pages

-

VZ300L/VZ500L

6 Pages

-

Linear EDM Range

20 Pages

Archived catalogs

-

AP1L/AP3L

8 Pages

-

Linear Motor EDM AD35L

4 Pages

-

SLG

8 Pages

-

SLQ

2 Pages

-

AQ400L

8 Pages

-

VZ300L

2 Pages

-

AQ45L

6 Pages

-

AD30L

6 Pages

-

Product Range

6 Pages

-

Sodick - Linear Motor Wire EDM

13 Pages

-

Sodick - Linear Motor Sinker EDM

12 Pages

-

Sodick - High Speed Hard Milling

22 Pages

-

Sodick - Small Hole EDM

6 Pages