Catalog excerpts

create your future Smart Pulse Smart Linear

Open the catalog to page 1

The Spirit of “Create, Implement and Overcome Difficulties” Based on the mindset of "assisting in the product development of customers", Sodick has listened to the demands of customers no matter how insignificant, and has challenged and overcome every difficult technical issue to solve problems. The company has also maintained the stance where Sodick even develop products in-house to solve a problem, if its solution is not available anywhere in the world. Linchpin of man The origin of Sodick the company name, is derived from the spirit of not hesitating to "Create(So)", "Implement (di)",...

Open the catalog to page 2

Creating Future Based on the founding philosophy “Create, Implement, Overcome difficulties”, Sodick strives to be a company that contributes to society by providing products of various kinds for “future creation”: creating a future that is energy-efficient, safe, and eco-friendly, a future with the state-of- the-art technology and with high hopes. nufacturing of the world Message from Management It is our mission to create and deliver machine tools that clients find rewarding to use. In our ceaseless commitment to our corporate principles of "Create, Implement and Overcome Difficulties”,...

Open the catalog to page 3

Linear Motor Drive High Performance Wire-cut EDM Through in-house development and manufacturing of all elemental technologies including linear motors, discharge power supply, NC unit, motion controller and ceramics, the ALC series delivers overwhelming performance based on the “Smart Pulse & Smart Linear” concept.

Open the catalog to page 4

Integration of Sodick's linear EDM experience and know-how perfected over 20 years Sodick has launched a brand new Premium Wire-Cut EDM Series the ALC series. Based on the latest digital innovations in generator technologies, the new ALC Premium range demonstrates considerable advances in cutting speed, accuracy and surface finish. This achievement was made possible through 20 years of Sodick Linear Technology. The Smart Pulse Generator drastically reduces the number of cuts necessary to achieve the required accuracy and surface finish, compared with conventional machines. This reduction in...

Open the catalog to page 5

Electrical Discharge Power Supply Unit The unit contains numerous circuits to optimally control electrical discharge energy. High speed, quality rough cutting essential for finishing is controlled through an optimum discharge pulse to achieve superior surface and form accuracy. The electrical discharge power supply unit To Realize Products Satisfying the World’s containing these circuits is based on energy Strictest Standards, Sodick Develops the saving design that works to minimize Advanced In-house Made Core Technologies. wasteful energy loss. The development philosophy espoused by Sodick...

Open the catalog to page 6

Due to the extremely small thermal displacement, ceramic is ideal material for use in electric discharge machines. In addition to perfect hardness, light weight, heat resistance, and low wear characteristics, ceramic has electric insulation properties as well, which is important for electrical discharge machines. By using ceramic components, high quality machining surface can be ensured in small areas without the need for any special jigs. Linear Motor Sodick's linear motor provides high acceleration and positioning accuracy without backlash, by a direct drive mechanism without any single...

Open the catalog to page 7

The ALC Series is equipped with the all-new "SPW Power Supply Unit" with a Multi-touch LCD monitor to bring new innovations in operability. In addition, the unit is equipped with a high-speed dual core processor. With operability optimized with a LCD monitor system, the unit creates an innovative environment in which workers can perform all necessary work through simple touch operation.

Open the catalog to page 8

Equipped with the NEW “SPW” Controller Newly developed High-speed motion controller 1 Gbit/sec high-speed serial communication K-SMC LINK Equipped with high-speed Dual Core processor Low power consumption Improved linear motor control performance New user interface NC Unit employs 19” Multi-touch LCD Coordinate Setup Screen Maintenance Screen Machining Condition Screen Workpiece Allignment Screen

Open the catalog to page 9

Smart Pulse Electrical Discharge Power Supply Unit The unit contains numerous circuits to optimally control electrical discharge energy. High speed, quality rough cutting are essential for finishing and are Surface roughness, machining accuracy and machining speed can controlled freely The Smart Pulse (SPW power supply) demonstrates overwhelmingly high performance in all areas from the first cut to finish machining. The high peak current during rough machining to the extremely fine discharge pulse during superfine finish machining, can be controlled freely. The performance was improved in...

Open the catalog to page 10

Ultra Surface Finish ALC series provides “Digital PIKA W Plus” as Standard. The transistor-generate current is optimized to save machining energy, also to prevent corrosion by electrolysis free circuit. Using Smart Pulse (High-speed & no electrolysis), Industry’s best surface is given. Machining Speed ALC series provides Ultra high speed & electrolysis free “Smart Pulse – TM circuit” as standard. “Smart Pulse” prevents oxidation, weakening and corroding which occurs when using deionized water. Ionic current is controlled while providing high-frequency bi-polar short pulse into electrode...

Open the catalog to page 11

Since 1998 when linear motor drive system was first introduced to the industry, over 4: machine products have been delivered globally with more than 20 years of track record for its long-term reliability and performance. Sma Comes with world standard Heidenhain linear scale Employs a projection method linear scale which uses projected light as a signal. ^ Encoder scale with extremely fine grid interval > Guarantees minimum position error. As soon as the power is switched ON, position data is acquired from the encoder. > Origin position search motion is unnecessary. ■ > Reduction of origin...

Open the catalog to page 12All Sodick catalogs and technical brochures

-

Linear Product Range 2019

28 Pages

-

HS430L

2 Pages

-

HS650L

2 Pages

-

UH430L/UH650L

16 Pages

-

AQ1200L Premium

2 Pages

-

AQ900L Premium

2 Pages

-

OPM250L

24 Pages

-

Produkt Range Brochure

28 Pages

-

ALC600G

2 Pages

-

ALC400G

2 Pages

-

OPM350L

2 Pages

-

AP250L

2 Pages

-

AQ1500L

2 Pages

-

AQ1200L

2 Pages

-

AQ750L

2 Pages

-

SLC600G

2 Pages

-

SLC400G

2 Pages

-

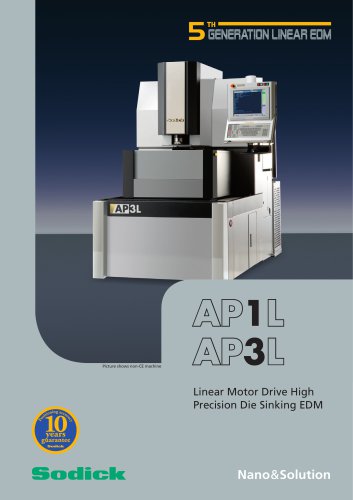

AP3L

2 Pages

-

AQ15L

2 Pages

-

AG100L

2 Pages

-

AG80L LST

2 Pages

-

AG40L

2 Pages

-

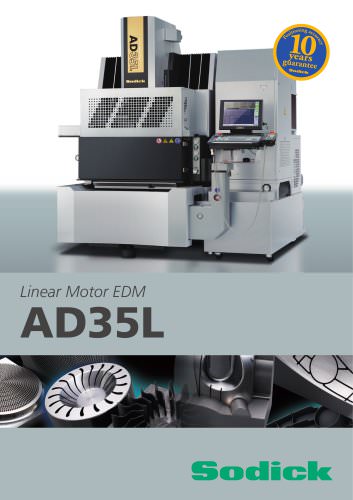

AD35L

2 Pages

-

AP1L

2 Pages

-

K1C/K3HN

4 Pages

-

VL400Q/VL600Q

4 Pages

-

Linear Product Range

24 Pages

-

AG80L LST / AG100L

4 Pages

-

AQ15L / AQ20L

4 Pages

-

AG40L/AG60L/AG80L

16 Pages

-

AD35L / AD55L

4 Pages

-

ad55l

2 Pages

-

aq20l

2 Pages

-

AP250 L

6 Pages

-

SLC-G Series

8 Pages

-

VZ300L/VZ500L

6 Pages

-

Linear EDM Range

20 Pages

Archived catalogs

-

AP1L/AP3L

8 Pages

-

Linear Motor EDM AD35L

4 Pages

-

SLG

8 Pages

-

SLQ

2 Pages

-

AQ400L

8 Pages

-

VZ300L

2 Pages

-

AQ45L

6 Pages

-

AD30L

6 Pages

-

Product Range

6 Pages

-

Sodick - Linear Motor Wire EDM

13 Pages

-

Sodick - Linear Motor Sinker EDM

12 Pages

-

Sodick - High Speed Hard Milling

22 Pages

-

Sodick - Small Hole EDM

6 Pages